Loading a bobbin on a sewing machine is not as difficult as it might sound. It’s a simple process that involves just a few steps, but if you take the wrong steps, it can lead to lots of frustration and extra work. So here’s how to do it the right way and get your bobbin loaded quickly and correctly.

Step 1: Wind the Bobbin

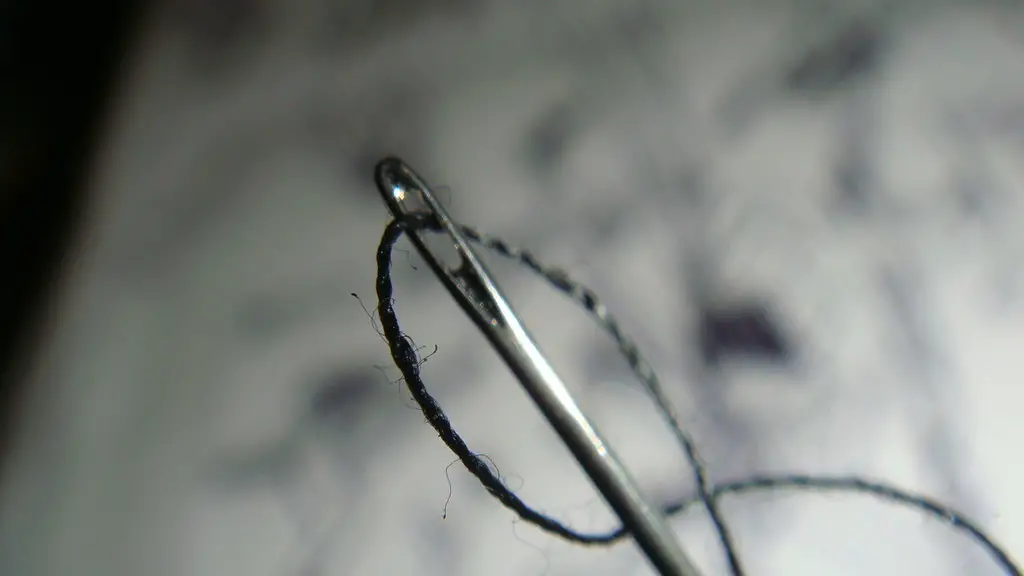

Before loading the bobbin, you’ll need to wind it with the thread that you plan to use. Most sewing machines will have a bobbin winder mechanism so you can easily wind it up. Start by inserting the bobbin into the winder and then pressing the winder button. As the thread comes from the spool, guide it around the bobbin and push the bobbin into the winder until it’s completely wound up.

Step 2: Place the Bobbin in the Bobbin Case

Once the bobbin is wound, slide it into the bobbin case. It should fit snugly, so make sure it’s secure and won’t fall out. The bobbin typically goes in the bottom of the bobbin case, so check the machine manual if you’re confused. Some machines will also have a cover that you’ll need to open and close once the bobbin is in place.

Step 3: Insert the Bobbin Case into the Machine

The next step is to insert the bobbin case into the machine. The bobbin case typically goes between the needle and the machine’s feed dogs. Be careful when inserting the bobbin case, as the needle could be sharp and cause injury if you slip. Once the bobbin case is securely inserted, you can thread the machine and then start sewing.

Step 4: Monitor the Bobbin Thread

As you sew, periodically check the bobbin thread. If the thread ends in the middle of a seam, you’ll need to re-thread the machine and replace the bobbin. Most machines will also have a way to monitor the thread level, usually a small window on the bobbin case. Whenever the thread level is low, it’s time to replace the bobbin.

Tips and Troubleshooting

If you’re having difficulty loading the bobbin, it’s probably due to a few common issues. First, make sure the bobbin isn’t winding too tight. If the bobbin won’t wind, it could be due to a defective bobbin. In this case, you’ll likely need to replace it. Finally, always make sure the thread is going in the correct direction. If you thread it in the wrong direction, it won’t be properly loaded and you’ll need to start over.

Replacing the Bobbin

If you need to replace the bobbin, the process should be similar to loading it. Start by winding the thread around the bobbin, making sure to keep the thread tight. Then, insert the bobbin into the bobbin case and place the bobbin case into the machine. Finally, thread the machine and start sewing.

Inspecting the Bobbin

If you’re having trouble with the bobbin, it may be due to a defect. To check, inspect the bobbin for lint build-up or rust. If there is lint, use a soft brush to remove it. If rust is present, the bobbin may need to be replaced.

Maintenance and Cleaning

If your bobbin keeps jamming or winding incorrectly, it could be due to a lack of maintenance and cleaning. In this case, make sure to periodically clean the bobbin case and the bobbin itself. You can do this with compressed air or a soft brush, as long as the tool is appropriate for the material the bobbin is made from.

Storing the Bobbin

Once you’re done sewing, make sure to store the bobbin and the bobbin case correctly. Many machines have storage compartments for the bobbin and the bobbin case, which is the best way to store them. If your machine does not have storage compartments, you can store the bobbin and bobbin case in an air-tight container or plastic bag. This will help protect the thread and keep it from becoming tangled or damaged.

Troubleshooting Common Problems

Sometimes even with correct loading, your bobbin can still jam or misfire. This is usually caused by a lack of tension, or too much tension. If you’re having this issue, make sure to check the tension and adjust it as needed. It’s also a good idea to check for any lint or thread buildup in the bobbin case or on the bobbin itself. If these are present, the bobbin won’t move smoothly and you’ll need to clean the machine before sewing again.

Choosing The Right Bobbin

When it comes to loading the bobbin, it’s important to pick the right one for your machine. Most machines require a specialized bobbin, so make sure to check the sewing machine manual before purchasing. It’s also a good idea to get extra bobbins to ensure you always have a backup in case your bobbin runs out or gets damaged.

The Best Practices for Loading a Bobbin

Overall, the best way to load a bobbin is with patience and expertise. Make sure you have a good grasp of the instructions from your machine’s manual, and take it slow. Don’t rush through the steps, as this can lead to mistakes. Instead, think through each step and be sure you don’t miss any details. This will help you avoid frustration and save time in the long run.