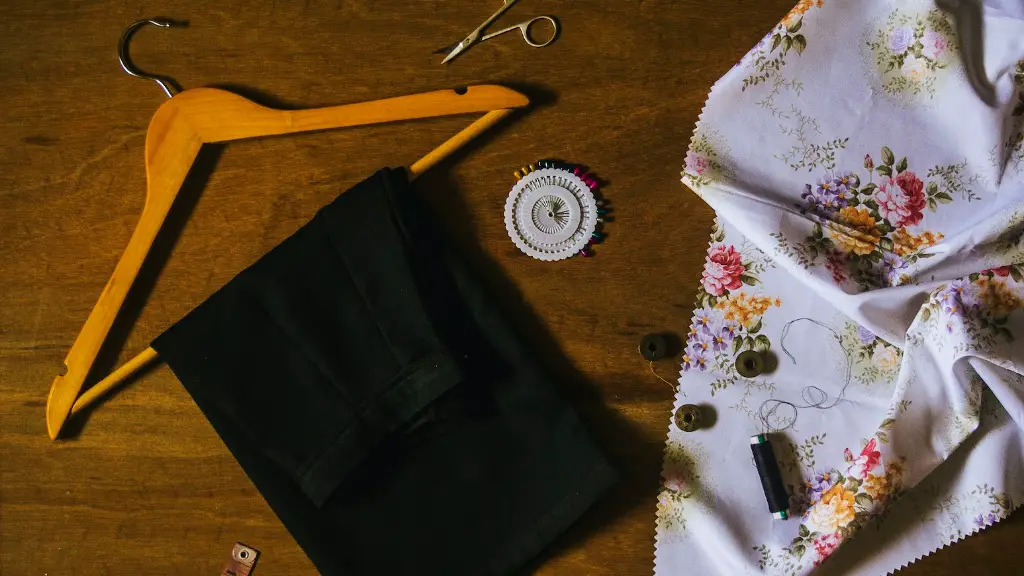

Tools for Making a Buttonhole on a Singer Sewing Machine

Having the right tools for the job is essential when making a buttonhole on a Singer sewing machine. A good sewing machine will come with the standard presser foot, but it is wise to invest in more specialized tools to take on the complex task of buttonholes.

For an optimal result, a special presser foot for a zipper and buttonholes are ideal. This presser foot will slot into the side of the sewing machine, and will have an adjustable width and length for different size buttons. A set of sharp scissors will also be required to cut the material after the buttonhole is completed.

Preparation and Set Up

Once the right tools are collected, the buttonhole can be prepared. It is important to select the right thread and fabric, taking into account the weight and texture of the material, as well as the size and shape of the button. Extra factors to consider when selecting the right fabric are the required pattern allowance and the depth of the buttonhole.

The material is then placed under the sewing machine presser foot and the button is fitted into the foot. The needle should be positioned to the highest point, so it is appropriate for the buttonhole size. The machine should also be set to the appropriate stitch length and stitch width, which typically changes for different fabrics and patterns.

Sewing the Buttonhole

Once the machine is set, the buttonhole can be sewn. The machine’s silhouette feature can be used to start the project and the foot should be deployed in order to begin the pattern. The thumb lever can be used to sew forward, stitch by stitch, and the foot should be moved according to the pattern instruction.

The machine will usually move the needle in and out of the material while it is stitching, so it is important to keep a steady hand on the material to ensure it does not move or bunch. Once the stitches are finished, the needle should be pushed to its highest point and the machine can gently backtack, which will keep the end of the stitches secure. The fabric should then be trimmed to the side of the buttonhole and the buttonhole is finished.

Assessing the Final Result

When assessing the final result it is important to identify if the buttonhole fits the button correctly. If the button is too small, the result may be a loose buttonhole, while conversely, if the button is too large, the button will not fit correctly into the buttonhole. A suitable size button should fit perfectly into the buttonhole. Once the right button is chosen, checking the alignment of the buttonhole is essential. The buttonhole should be perfectly straight and should fit the fabric neatly.

Troubleshooting

If the buttonhole appears too small, the thread tension of the machine may need to be adjusted, which can usually be fixed by loosening up the thread. If the buttonhole appears too large, the tension should be adjusted, by tightening the thread. The needle should also be adjusted and changed if needed. If the buttonhole appears misaligned, the needle bar should be checked and adjusted to the correct position.

Tips for Perfect Buttonholes

The perfect buttonhole comes from careful preparation and good use of the machine settings. Taking the time to select the right thread and material type for the project is key. A short stitch length and a medium to wide stitch width will be the optimal settings to use. Practice the sewing technique in order to gain a steady hand, as well as using presser feet and steady thumbs when moving the machine.

Getting Professional Results

Receiving professional results with buttonholes requires detailed instruction when setting up the sewing machine. The stitch length, width and tension must be selected based on the fabric type and size of the button. The style selections of the machine should also be reviewed and moderate settings used in order to receive the best results.

Using Specialty Feet

Specialty feet are designed for specific sewing tasks such as buttonholes. The operator should get familiar with the feet and learn how to use them correctly both on and off the machine. Familiarizing with the feet will also help getting more professional results on any task.

Planning the Project Ahead

By planning the project ahead the operator can save time, materials and money. The tools, fabrics and machine settings need to be selected before starting the project. Making a trial sample with scrap materials will also be time-saving and it helps the operator to refine the techniques used when sewing a buttonhole.

Finished Products

Once the buttonhole is completed it should be moved away from the sewer to cool and check if it is correct. If the buttonhole appears as desired it should be pressed with a warm iron until it is properly set. Once the fabric is cooled down any loose threads should be snipped off, and the button should fit perfectly into the buttonhole. The garment should now be ready to wear.