Troubleshooting Tips to Make a Sewing Machine Work

Sewing machines can be confusing and intimidating if you are new to them. Often, experienced sewers will have done certain things that may work for them, but may not work for you. In order to get the most satisfaction from a sewing machine and the neatest stitches, the following tips can help anyone, regardless of experience level, make the machine work for them.

Correct Thread Type

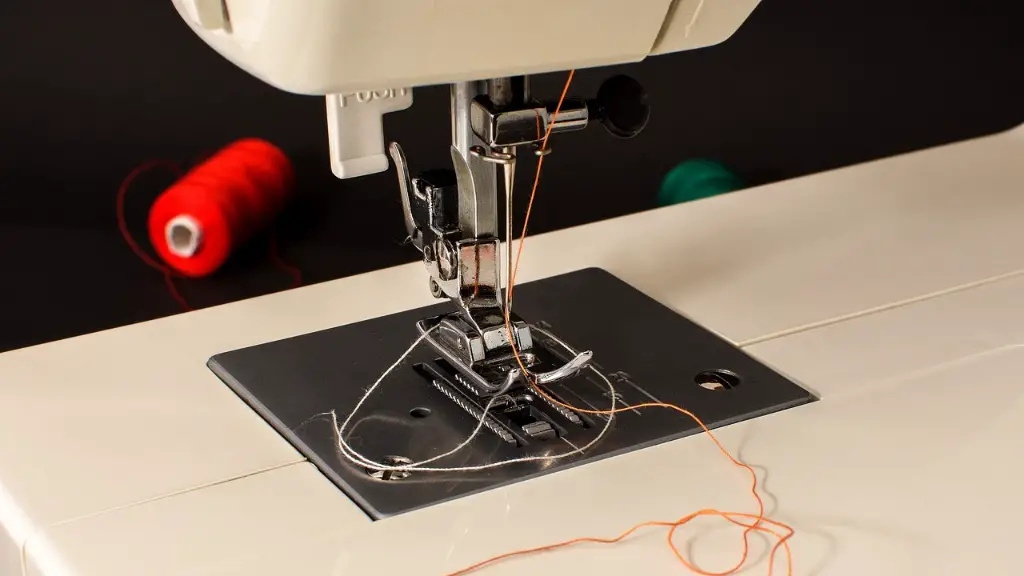

One of the most deeply rooted issues with running a sewing machine is that the wrong type of thread has been used. All sewing machines have a specific tension disk gauge they use, so it is important to use the correct type of thread. Using an incorrect type of thread can cause difficulties with stitching, especially if the wrong weight of thread is chosen. It is also important to use correctly labelled sewing machine needles.

Check Settings

Settings on a sewing machine are incredibly important, and even experienced sewers should double check them before beginning any project. Settings should be set according to the type of stitch and the thickness of fabric being used. For example, zig zag stitches should normally be set higher than straight stitches, and for two layers of denim, higher settings are needed than for lighter fabrics.

Tension Control and Tension Discs

Tension control is one of the most important aspects of a sewing machine, and the tension needs to be checked often. If the tension is too tight, it will create a puckered stitch, while if it is too loose, the thread will be more prone to breaking. The tension disk must be cleaned on a regular basis and is especially essential when winding the bobbin.

Check Sewing Path

If stitch length and tension don’t seem correct while sewing, it is important to check the sewing direction on the machine. Most sewing machines have an arrow indicating the sewing direction, so it’s important to check this first to make sure the fabric flows with the arrow.

Adjusting the Stitch Length

Stitch length for any machine can be adjusted, although the sewing machine instructions will differ for each machine. Generally, adjusting the stitch length slightly can fix issues in tension or puckering. For instance, if the fabric is puckering and gathering, then a shorter stitch length should be used. Conversely, if the stitches are too tight or close together, a longer stitch length should be used.

Oil the Machine Regularly

Sewing machines need to be oiled about once a month or every time the machine is used, depending on the manufacturer’s instructions. Oiling helps to keep the parts of the machine moving smoothly, and lack of oil can cause the metal parts to corrode. Sewing machines also need to be cleaned regularly, as any buildup of dust or lint can get caught in the moving parts of the machine and cause issues.

Overhaul the Machine Every 5-10 Years

Sewing machines should be overhauled ever 5 to 10 years, depending on the frequency in which it is used. Overhauling includes taking the machine apart, cleaning it, and re-lubricating it. It can be done at home, although it is recommended that a technician be consulted to ensure that the machine is reassembled correctly. Missing parts can cause the machine to no longer function correctly.

Check Electrical Connections

If the sewing machine seems to be running slower or faster than usual, then it is important to check the electrical connections. Worn out connectors can cause the machine to run at an inconsistent speed. If the electrical cords and wires look worn, they should be replaced. Also, be sure to check the power source itself, as well as the socket or plug for possible issues.

Learning How to Use the Machine

If all of the other tips have been followed, but the machine still not working correctly, then it’s time to consider taking a class on how to use a sewing machine. Taking a class is the best way to learn about troubleshooting and all of the technical aspects of a sewing machine. Learning how to troubleshoot any common problems associated with a sewing machine can save a lot of frustration in the long run.

Storing the Machine Properly

Once all of the other tips have been followed and the machine is running properly, it’s time to consider storing it properly. Regular cleaning and dusting of the machine with a soft, lint-free cloth is essential. Storing the machine in an area with low humidity can prevent rust and corrosion. The machine should also be covered with a cloth when it is not in use and extra care should be taken when transporting it.

Check the Manual

Once all of the above tips have been exhausted, the best way to make sure the sewing machine is running correctly is to check the user manual. It is important to read, understand, and follow the manufacturer’s instructions for proper maintenance and use of the machine. The manual can provide additional information about the machine and can answer any questions that may arise.

Avoid Unnecessary Adjustments

Most sewers don’t need to adjust their machine all the time in order to make it work properly. Adjustments should only be made if a certain stitch or tension isn’t working correctly. Over-adjusting the machine can cause it to stop functioning properly and is best avoided. If adjustments are needed, consult the manual or a tailor or repair professional to make sure it is done correctly.

Preventative Maintenance Tips

One of the best ways to keep a sewing machine running properly is to use preventative maintenance. Regular oiling and cleaning of the machine, as well as checking tensions and stitch lengths, will go a long way. Additionally, investing in a good quality machine cover and storing the machine in a dry area will help to ensure the machine runs properly for a long time.

Educate Yourself

Sewing machines, no matter how complex or simple, operate differently. If a user is having trouble figuring out how their machine works, taking a class or reading up on basic machine maintenance tips can go a long way. It is also important to remember that different models of sewing machines may require different maintenance tips.

Conclusion: Proper Maintenance and Care Keep Machines in Peak Condition

Whether a novice sewer or an experienced one, troubleshooting tips can help make any machine run properly. Following the manufacturer’s instructions and consistently upholding preventative maintenance procedures will help to keep a machine running smoothly and in peak condition. A bit of knowledge and upkeep can get any type of sewing machine up and running properly.