Gathering Materials

Making jeans with a sewing machine requires basic sewing supplies and a few jean-specific materials. Cloth for the jeans legs will require about 2.5 yards depending on the desired length. Thread needs to be heavy-duty, such as denim or upholstery thread, and should be strong enough to link the components of the jeans together securely. Be sure to purchase topstitching thread for a professional finish. Jean-specific materials also include rivets, jeans buttons, and a zipper to add a fly to your jeans. To create the guideline for the stitching, an erasable fabric marker is essential. Sewers can also use a pair of jeans that fits properly as a model to replicate.

Preparing the Pattern

In order to make the jeans, a pattern must be created. In order to do that, a few measurements must be taken that will give sewers the size of the jeans they will make. Measurements include the waist, hip, back rise, front rise, thigh circumference, knee circumference, inseam, and outseam. With the appropriate measurements in hand, sewers can either draft the pattern themselves or use a commercial pattern to follow. If sewing from an existing pair of jeans, unpick the seams and trace the pieces onto tracing paper.

Cutting Out The Pieces

Lay out the jeans material on a flat surface ensuring that all pieces are facing the same direction and cut out the pattern pieces with sharp scissors. As sewing denim can be tricky, it is important to lay out the pieces with the grain. To find the grain, locate the pulled thread and cut along it. As jeans usually have at least two pockets, be sure to trace the pocket shapes onto the fabric, so that the pocket details can be cleaned and stitched properly.

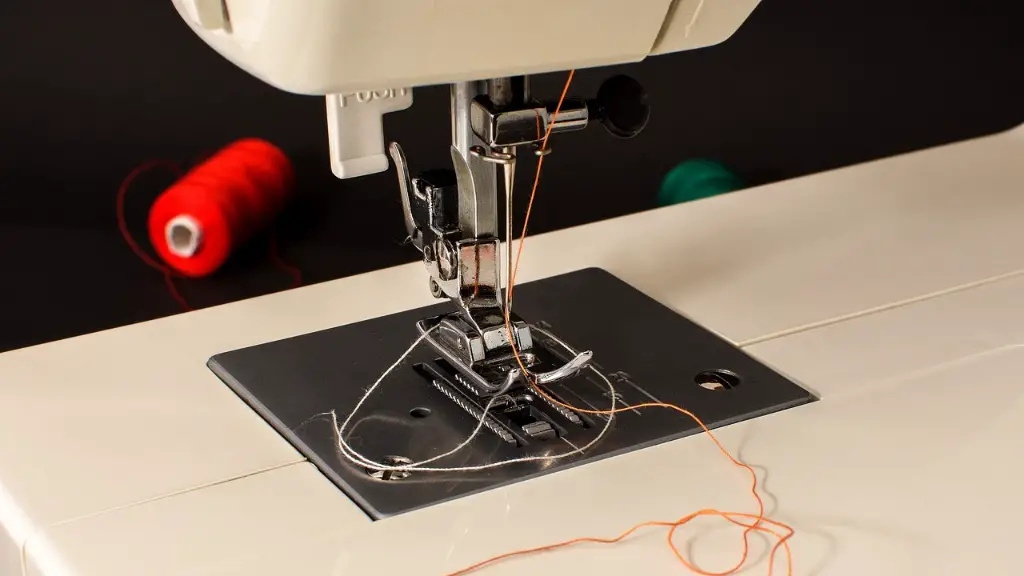

Stitching

Traditionally, the top-stitching was used to prevent the seams from unraveling as opposed to only being decorative. It is vital to use a longer stitch length and heavier thread when stitching so jeans will have a strong, finished look. Using the sewing machine, start stitching the seams. Use an edgestitch foot for an overall professional finish. Follow the pattern instructions for assembling the jeans.

Finishing Touches

Jeans require a few extra details to have a professional finish. Some of these include securing the fly and riveting the pockets. A jeans zipper foot for the machine is useful for stitching the zipper and jeans buttonholes. Rivets can also be attached using a rivet machine.

Adding Details

Jeans need to look personalized as this adds to their charm. Adding pockets, patches, embroidery, and embellishments are just some of the details that can be added. To add these details, sewers need to stay creative and be aware of what they are capable of completing.

Troubleshooting

Certain problems may arise when sewing jeans such as puckering, uneven stitches, or bulky seams. To fix these mistakes, sewers need to step back, determine the issue, and make the necessary adjustments. If the problem is with the stitching itself, it is possible to unpick the stitches. Unpicking will require patience, but it will help to fix the stitching issue and prevent any future problems.

Tools and Techniques

When making custom jeans, a few tools and techniques need to be used. Sewers need a sewing machine equipped with a jeans foot, an appropriate stitch length, and a denim or upholstery-strength thread. It is also important to use an upholstery needle. Proper pressing tools are needed throughout the process such as a ham to taper the side seams. Seam rolling tools will help to create even seam allowances. Hammering the rivets and other pocket details down with metal setting hammers will make sure the components on the jeans are secured.

Creating Custom Fits

When making jeans, sewers don’t have to stick to a commercial pattern. With the right measurements, the jeans can be made to fit the individual. However, if one is more experienced, they can choose to create more intricate details such as kick pleats, inserting gussets, or adding waistbands.

Marking and Notching

Marking and notching the jeans are essential for accuracy in construction. It helps to memorize where to mark the notches and put a dot for the intersections on the paper pattern. Remember to mark the pockets as well when cutting out the jeans from the fabric. Investing in quality tools like pattern weights and tracing paper can be helpful.

Topstitching

Topstitching is essential for a professional, finished look for your own jeans. For jeans, the standard stitch length is 3.5 or 4.0 on a medium-weight cotton setting. Thread needles properly and don’t forget to replace the standard presser foot with an edgestitch foot if you have one. Remember to use a smaller stitch and thinner thread to alternate the needle positions between 3.2 and 3.5.

Testing the Fits

It is important to check the fit of custom jeans while they are still in process. The fit of the waistband should be snug on the body, and be sure to try them on before the waistband is sewn down. Additionally, the other components need to be tested for proper fit and mobility of movement, such as the rise and the legs.

Know How to Use the Sewing Machine

When starting a project, it is important to know how to use all parts of the sewing machine. If someone has limited experience with a sewing machine, they should watch videos and tutorials to learn more about its features, functions, and capabilities.

Using the Right Needles

The right needle is essential when making jeans, as the wrong needle can easily rip the fabric. Denim needles are specifically designed for denim fabric and are essential for a high-quality finish. Be sure to use an upholstery needle for layers of fabric or heavy-duty thread.

Working with Accessories

Adding rivets, buttons, and a zipper to the jeans fly is essential for a finished look. Sewers must purchase jeans buttons and rivets made from heavy duty and heat-resistant material. It is possible to attach the accessories manually or with a specialised machine. Specialised machines for adding accessories are easy to use and add a professional finish on the jeans.

Choosing the Best Fittings

When making jeans, sewers can use the best-fitting fittings to make the jeans really pop. These include belt loops, waistbands and pockets. Belt loops are usually made out of loose double welt; the two-piece construction ensures durability and longevity. Quality pockets should also be used, as regular stitching is not strong enough to hold the contents of pockets. Waistbands can be made with a variety of materials, including denim and wool, depending on the look desired.