Maintenance of Singer Simple Sewing Machines

Singer Simple Sewing Machines are great for sewing projects of any kind. Although they are an older model machines, they are still often relied upon for a variety of uses. To keep your Singer Simple Sewing Machine running in top condition, it needs to be regularly serviced and oiled. Oiling the machine is often overlooked, but is essential in keeping it in optimal health. This article will provide a beginner’s guide on how to oil a Singer Simple Sewing Machine.

To prepare the machine for oiling, the first step is to unplug the machine from its power source. Also, be sure to open the machine and locate the rotating parts inside. It’s important to note that Singer Simple Sewing Machines do not require frequent oiling, but must be oiled at least once every year. Oiling too often will lead to deposits of lint and dirt, which will cause the parts to accumulate more dirt.

The next step is to choose the right oil for the machine. Singer recommends a lightweight household oil such as 3-in-1 oil. These oils have a thinner consistency than other oils and will make sure the moving parts are smoothly lubricated. It’s important to note that Singer recommends against using sewing machine oil as it is too viscous and will attract extra dirt.

When oiling the machine, use a small flat-tipped screwdriver or an oiling needle depending on which parts need to be oiled. It is important to be very specific when applying oil, as too much can lead to an accumulation of dirt and lint, as well as cause the parts to seize up. Oil the rotating parts on the side of the machine located within the bobbin area by avoiding the gears. Be sure not to oil within the location of the needle or the shuttle race, as this will cause the machine to no longer sew properly.

When oiling the machine, the goal is to oil those parts that touch when the machine is running, such as the bearings and gears. Start by applying a few drops of oil onto the contact points, then move to the feed dogs that are located at the back of the presser foot. A few drops of oil should be applied to the front and back of each feed dog. It is important to avoid over-oiling, as this can cause buildup and seizing up of the parts.

Finally, after the oiling is done, it’s important to unplug the machine again and check for any excess oil. Use a paper towel to wipe away any excess oil that may be visible on the machine. With the machine’s power off, move the handwheel by hand to make sure all the parts are moving smoothly and were properly lubricated.

Cleaning a Singer Simple Sewing Machine

Regular cleaning of your Singer Simple Sewing Machine is often overlooked, but just as important as oiling. As dirt, lint and thread accumulates, it can lead to the machine not sewing straight and can even cause malfunctions. To begin cleaning the machine, make sure it is unplugged and remove the bobbin and needle.

Using a soft brush, brush off and remove any dust or dirt that may be present. Be sure to vacuum around the machine to remove any hidden debris. A can of compressed air can be used to blow built-up lint and dirt from difficult to reach areas of the machine. Take caution when using compressed air, as excessive air pressure can cause damage to the internal components.

When cleaning the machine, be sure to avoid any water contact. Using a dry cleaning cloth, gently wipe and clean the faceplate and other areas of the machine. Check for any excess buildup of lint or thread and use a pair of tweezers to remove them. With the bobbin and needle removed, use the brush to gently clean around the bobbin and needle areas.

It is also important to check the tension discs and pick the threads that may have been left behind due to improper tensioning. This can help avoid any future buildup of thread or lint and can help enhance the accuracy of the stitches. Finally, use a can of compressed air to gently blow any remaining debris from the machine

Properly Threading a Singer Simple Sewing Machine

Threading a Singer Simple Sewing Machine is a relatively simple process. Begin by pressing the tension release button located on the top left side of the machine. This will ensure that the tension discs are properly released for re-threading.

Next, with the threading guide in the take-up lever, insert the thread in the needle from back to front. Then, guide the thread around and beneath the thread guides and back up to the spacing bar. With the tension discs still released, pull the thread through the tension discs on the top left of the machine. Finally, guide the thread back down the tension bottom, but leave a tail of thread.

Once the thread has been properly threaded, the next step is to slide the threading guide back into its original position and close the tension release. Pull the thread up through the take-up lever and adjust the top thread tension or the lower tension accordingly. It is important to test the thread tension with a sample project before starting on the project.

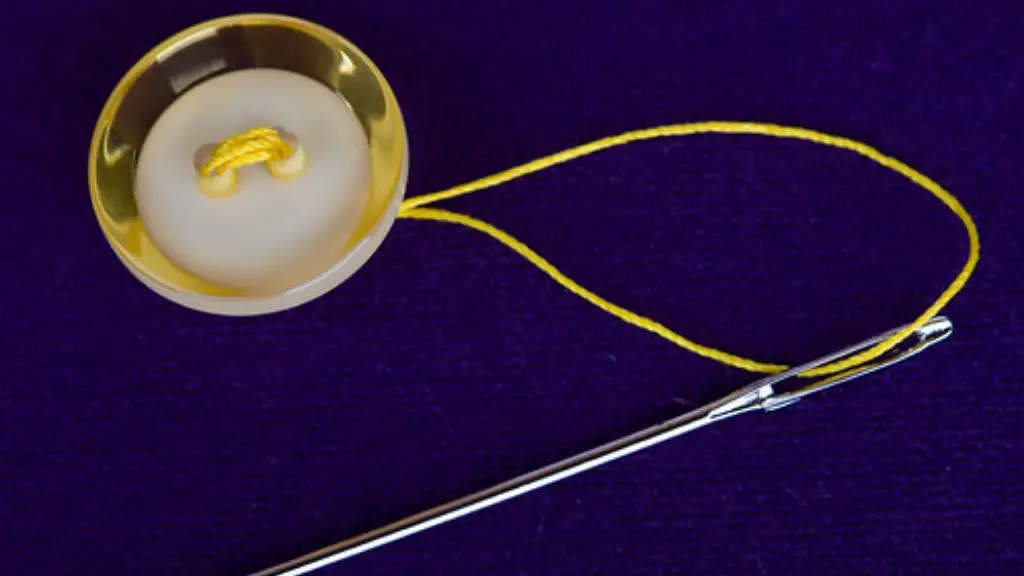

With the threading complete, the final step is to thread the bobbin. As bobbin threading techniques vary from machine to machine, it is important to consult the Singer Simple Sewing Machine’s manual for the detailed instructions. With the bobbin threaded correctly, the machine is ready for sewing.

Replacing the Needle

Replacing the needle on a Singer Simple Sewing Machine is an easy process. Begin by unplugging the machine, and then raising the presser foot and removing the needle. Use a small screwdriver to unscrew the needle clamping screw on the needle plate and remove the screw and the needle.

It’s best to use a Singer specified needle for the machine. Inserting the wrong type of needle can cause damage to the machine as it may not fit into the needle plate properly. When inserting the needle, make sure the flat side of the needle is facing in the direction of the back of the machine. With the needle in place, use a tiny drop of oil, Singer 3-in-1 oil is recommended, on the needle shank.

Then, screw the needle clamping screw back into place with the needle and the needle plate. Be sure to use the screwdriver to tighten the needle clamping screw and make sure it is securely in place. Finally, raise the presser foot and test the machine to make sure the needle is properly in place.

Troubleshooting a Singer Simple Sewing Machine

If a Singer Simple Sewing Machine is malfunctioning and not sewing properly, it is important to first go through the troubleshooting steps before taking it to a repair shop. Begin by checking the tension, as the tension discs may need to be adjusted. Take a look at the threading of the machine and make sure it is properly threaded. If the machine is properly threaded, try re-threading it to see if that resolves the issue.

If the machine is still malfunctioning with the proper threading, check the needle. Make sure it is the correct size and type for the project, and that it is properly inserted into the machine. If the needle appears to be inserted properly, try replacing it with a new one. It is also possible the needle may have a burr or be bent, and in this case, it should be replaced.

The bobbin may also be the cause for the machine not sewing properly. Make sure the bobbin is properly inserted and that it is wound with the right type of thread. It is also important to make sure the tension is set correctly, if it is too tight, the machine could struggle, and if it is too loose, the thread may not be wound properly.

If the machine is still malfunctioning, it may be time to take it to a professional to have it checked out. Many repair shops have certified Repair Technicians and experienced a Service Technician who specialize in Singer Simple Sewing Machines. These professionals can identify the issue and fix it professionally.

Conclusion

Singer Simple Sewing Machines require periodic maintenance, including oiling and cleaning. While oiling the machine, it is important to be very specific when applying oil, as too much can lead to an accumulation of dirt and lint. Cleaning the machine regularly can help keep it in optimal health and help ensure the stitches are accurate. Proper threading ensures the tension discs are properly adjusted for re-threading. Finally, replacing the needle is an easy process and can help resolve many issues.