Most modern sewing machines have electric bobbins, so it can be tricky to put a bobbin into a Bernina sewing machine as they have manual bobbins. Bernina sewing machines have additional cogs and springs, making threading and winding of bobbins more complex. The good news is that it is not a difficult task to do, and it can quickly become a second nature once regular practice is taken.

When threading and winding a manual Bernina bobbin, firstly, make sure it is the correct size to fit in the machine. Then, locate the bobbin itself – the needle plate should be removed and check whether the metal bobbin winder tension disc is pulled up and the bobbin holders inserted on and between the sides of the machine.

The thread should be placed around the spool pin and under the metal tension discs. Next, put the thread into the bobbin from the inside and wind it to the top. To do this, turn the small metal wheel on the side of the sewing machine, clockwise, using your thumb or forefinger whilst guiding the thread around the bobbin. Pull the thread all the way under the metal tension discs and wind a few turns. Wind the bobbin until it is full, making sure that the thread is evenly wound.

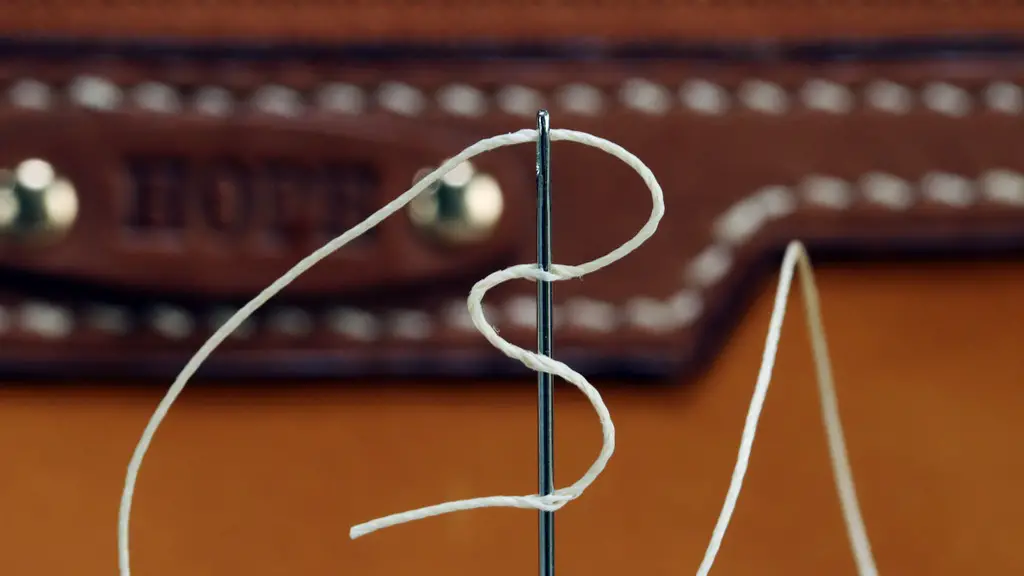

Once the bobbin has been filled, cut the thread on the side of the bobbin, ensuring that you leave enough thread hanging so that it is able to be threaded through the needle eye. Finally, align the arrow on the bobbin and different numbered knob to match with the shaft number on the Bobbin Case. Place the bobbin in the case and push down

Before threading the bobbin through the machine, raise the pressure foot and have the needle in its highest position. Pull out the thread from the bobbin and allow it to go down, to the left side of the machine. Then, turn the handwheel until the needle passes through the middle of the bobbin case. Make sure that the bobbin thread is coming out of the slot on the side of the case.

Finally, pull the top thread and bobbin thread together towards the back of the machine, then pull them towards the front of the machine, pushing the bobbin thread beneath the presser foot.Finally, pull the top thread and bobbin thread away from the machine and your bobbin is ready for sewing.

Planning

Though it might not be as complicated as winding an electric bobbin, putting a manual Bernina bobbin still requires careful planning. The size of the bobbin needs to match the machine and the bobbin holders need to be inserted so the fabric is held down. Next, the metal tension is adjusted and the thread is wrapped tightly and evenly around the bobbin.

Once the winding is complete, the bobbin thread and top thread should be pulled away from each other and the bobbin thread should be threaded through the needle eye. Threading the bobbin should always be done with the pressure foot raised and the needle in the highest position.

To ensure that the thread does not get tangled as it’s being threaded through the machine, there should be no tension and the stitch selection should be set to zero. If there are any concerns, it’s best not to force it and contact a professional for assistance.

Practicing

The task of putting a bobbin into a Bernina sewing machine is not difficult, however it does take practice to get the technique down and ensure that the bobbin is correctly threaded. Having a regular practice procedure is important and with enough practice, winding a bobbin can quickly become second nature.

For those who are instructing others, every step should be taken carefully and step-by-step. If there is any confusion, it is best to pause and break down the process into smaller steps and make sure all the necessary components are in place. Taking extra time at the start can prevent any mistakes from occurring.

Tools and Supplies

To ensure that the bobbin is correctly installed, the right tools and supplies should be collected before beginning the job. Supplies that are often needed are: new bobbins, thread, bobbin winding cogs, bobbin holder, and a pair of scissors. Additionally, since Bernina sewing machines have additional cogs, springs and tension discs, it is important to use the correct tools and supplies.

Having the correct tools and supplies helps to prevent any damage to the machine, as well as ensuring that it’s in the best condition to produce quality stitches. Any faulty tools can cause the thread to get tangled or the bobbin to be installed incorrectly, so it’s important to use the best quality supplies for this task.

Maintenance

Regular maintenance of the machine is necessary to ensure that it runs smoothly and produces quality stitches. Winding a bobbin is an important part of maintenance and helps to ensure that the thread is correctly fed through the machine. It also helps to reduce the chances of tension issues, as well as preventing the formation of lumps or knots due to excess thread.

In addition to winding bobbins, the machine should be regularly oiled and cleaned. This helps reduce dirt build-up and friction, preventing the rust and corrosion that can occur when left unattended. Additionally, the tension discs and cogs should be checked to make sure they are aligned and working correctly.

Safety

Whenever handling a machine, safety should be a top priority. It is important to make sure that the machine is unplugged before performing any type of maintenance work, in order to avoid any risk of electrical shock. Additionally, the machine should be cleaned regularly to reduce the chances of any dirt or debris getting stuck in the needles or the bobbin itself.

When winding the bobbin, it is important to use the correct size thread and to ensure that it is wound evenly and tightly. Any excess or loose threads can cause jamming of the machine and create tension issues. Finally, make sure to read the instructions for the machine thoroughly to ensure that all safety procedures are followed.

Troubleshooting

In the event that something goes wrong, it is important to troubleshoot quickly and efficiently to minimize the damage. If the thread becomes tangled, the best course of action is to unplug the machine and carefully remove the thread. This will allow the bobbin to be replaced and threaded correctly.

If the bobbin isn’t winding properly, it can be helpful to pull out the bobbin and rewind it, ensuring that the wind is even and there are no lumps or knots. If the machine gets jammed, it is best to switch it off immediately and check that the bobbin is correctly aligned and that the tension disc is in its correct position.

Conclusion

Putting a bobbin into a Bernina sewing machine is not a difficult task, but it is important to ensure that the machine is correctly setup and the bobbin is wound tightly. By gathering the right tools and supplies, taking safety precautions, and regularly practicing the technique, it can quickly become second nature.