How to Put Presser Foot on Sewing Machine:

Adding a presser foot to a sewing machine is an important task in the stitching process and can enhance the look of your fabric. Before you start adding a presser foot, though, it’s important to understand a few key concepts to make sure the process is safe, efficient and successful. This article will provide you with a step-by-step guide on how to put the presser foot on your machine, and then offer some tips for the best results.

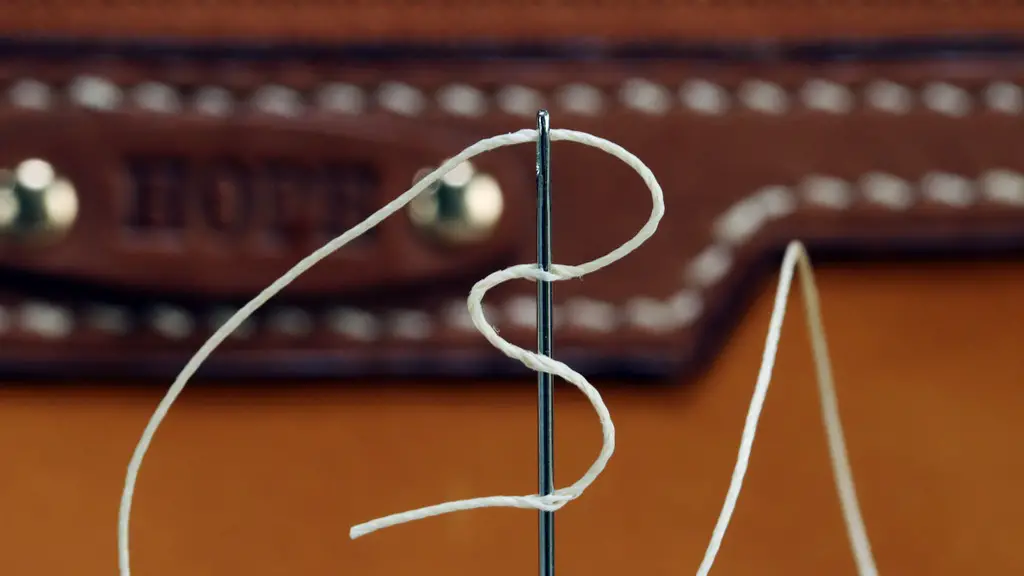

To begin, the presser foot needs to be connected securely to the sewing machine. If it isn’t, the needle could hit it and break, or the fabric may bunch up, resulting in uneven stitches. Take the appropriate size presser foot from the machine’s accessory item and match it to the machine’s shank. Align the post on the presser foot and the corresponding post of the shank, flip the foot over and then pull it down to make sure it’s attached properly. Most machines will have a locking lever or a pin which will keep the foot in place.

Once the presser foot is attached and secured, you’ll need to adjust the height of it. Generally, you should adjust it to the seam allowance that is printed on the pattern. If nothing is printed, use a standard 5/8-inch (1.6 cm) seam allowance, which is the most commonly used size. You can adjust the height of the presser foot with a dial near the shank.

Next, line up the presser foot so that it’s even with the needle before you begin sewing. You may need to raise or lower it to either side of the needle if you’re sewing with a zig-zag stitch or a wide seam allowance. Most sewing machines will have a guide for easily aligning the needle, but it may vary from model to model.

Once the presser foot is adjusted and ready to go, you’re ready to begin sewing. Before you start, it’s important to make sure that the needle is also properly aligned to the fabric. Make sure that it’s at the right height and that there is a good amount of room between the presser foot and the fabric. If there is too much pressure on the foot, it can cause the fabric to stretch, which will result in poor stitching.

In summary, adding a presser foot to a sewing machine is an essential step in any stitching project. With the right adjustment and alignment, you can ensure consistent, even stitches on any project. Now that you know how to put the presser foot on the sewing machine, let’s take a look at some additional tips for the best results.

Tips for the Best Results

When you’re attaching the presser foot, make sure it’s securely in place. If it isn’t, the needle may break or the fabric may bunch up and cause poor stitching.

When you’re adjusting the height of the presser foot, make sure it’s even with the needle before you begin sewing. Make sure there is adequate spacing between the presser foot and the fabric, or the fabric may stretch and cause poor stitching.

Use the recommended seam allowance that is printed on the pattern, or use a standard 5/8-inch (1.6 cm) seam allowance for the most commonly used size.

Check the condition of the needle periodically to make sure it’s in good working order. If the needle is bent, blunt or damaged, it can cause poor stitching.

When removing the presser foot, always do it in a downward motion so that it doesn’t get caught on the fabric. Don’t pull up on the foot, as this can damage the needle and the fabric.

What to Do if the Presser Foot Gets Caught

It’s not uncommon for the presser foot to get caught on the fabric while sewing. If this happens, carefully pull the fabric out from under the presser foot so it’s free. Then, adjust the presser foot back to the correct height and start sewing again. If it continues to get stuck, check the tension to make sure it’s set correctly.

You may need to adjust the tension as you move from one fabric type to another, as different fabrics may need more or less tension for the best results. Another issue could be the needle; it may be too large for the fabric, so switch out to a smaller, more suitable size if necessary.

Tips for Troubleshooting Presser Foot Issues

If you’re experiencing problems with the presser foot, take a few moments to troubleshoot the issue. Check the needle first to make sure it isn’t bent, blunt or damaged. If it is, replace it with a new needle. If the needle is in good condition, check the tension to make sure it’s set to the right level for the fabric you’re using. Finally, adjust the presser foot height, making sure it’s even with the needle.

If none of those solutions help, take a look at the presser foot and make sure it’s the correct size and type, and that it’s securely attached and aligned with the needle. If none of those solutions work, you may need to take the machine in for servicing.

Why Is It Important to Use the Right Presser Foot?

The presser foot does more than just hold down the fabric when sewing; it also helps guide the fabric in the desired direction and ensure even, consistent stitching. The wrong foot can cause the fabric to be misaligned or even bunched up, resulting in poor stitching. It’s also important to make sure that the foot is securely attached to the machine; if it isn’t, the needle may hit it and break.

Now that you know how to put the presser foot on the sewing machine and why it’s important to use the right foot, you’ll be able to make sure that all your stitching projects turn out perfectly.

Common Presser Foot Types

There are a variety of presser feet available for different types of sewing projects. The most common are the standard or all purpose foot, the zipper foot, the blind hem foot, the buttonhole foot and the teflon foot. The all purpose foot is the most common and can be used for a variety of fabrics and types of stitching. The zipper foot is used for inserting zippers, the blind hem foot for hemming fabric, the buttonhole foot for making buttonholes and the teflon foot for sewing fabrics that tend to stick.

Each of these feet will work on most machines, though some may require an adapter. It’s important to make sure that you have the right foot for your specific project and that it’s securely attached and adjusted properly.

Using a Presser Foot to Guide the Fabric

In addition to keeping the fabric from moving, the presser foot can also help guide the fabric when you’re stitching. By adjusting the position of the foot and the needle, you can guide the fabric in any direction you want. This is especially useful for intricate stitches and fabrics with more than one layer. This can be a helpful tool for any sewing project, from hemming a skirt to making a dress.

Now that you know how to put the presser foot on the sewing machine and some tips for using it, you’ll be able to ensure consistent, even stitches every time. With the right foot, the right tension and a little practice, you’ll be an expert in no time.