How to Reduce Tension on a Sewing Machine for Stress-Free Sewing

Sewing machines are complex pieces of equipment that require constant adjustment to keep them running at their best. Tension on a sewing machine is one area that has to be taken into account when working with fabric. If the tension is too tight, the stitch will be too small, resulting in frayed edges on your fabric, puckering, and weakened seams. If it’s too loose, the stitch will be too large, and the seam could come apart. Too much tension can cause stress points and thread breakage, as well as problems with your fabric.

Fortunately, keeping your tension settings just right isn’t too complicated. Here are some tips to ensure your next sewing project is a success and keep stress off your sewing machine.

Check the Needle

The needle installed on your machine is the first step in determining what the tension should be set at. Check the size of the needle and evaluate if it’s the correct size for the material you’ll be using. If the needle isn’t appropriate for the fabric it’s harder for the thread to pass through and that pushes the tension up. So, before you start a project, always make sure your needle is the correct size for your fabric.

Adjust the Presser Foot Pressure

The presser foot pressure of the machine is the amount of pressure used to hold the fabric in place while you are sewing. Too much pressure can result in tension problems, so it’s important to adjust it accordingly. If you are using a lightweight fabric, set the presser foot pressure to its lowest setting. For heavier fabrics, set it to a moderately high setting.

Check the Tension Balance

When you first thread your machine, check the tension. Make sure the balance of left and right tension is even. You can adjust tension for the left or right side (or both) to get the right balance. To do this, simply adjust the tension knob to the tension number specified in the owner’s manual.

Test Your Thread

Sometimes, even when all the settings are correct, you can still have tension issues. If that happens, test your thread to make sure it’s not the cause of the problem. With a simple test, you can determine the thread’s weight and thickness. This will tell you if it’s appropriate for the fabric and help you decide if it’s causing tension problems.

Clean the Machine

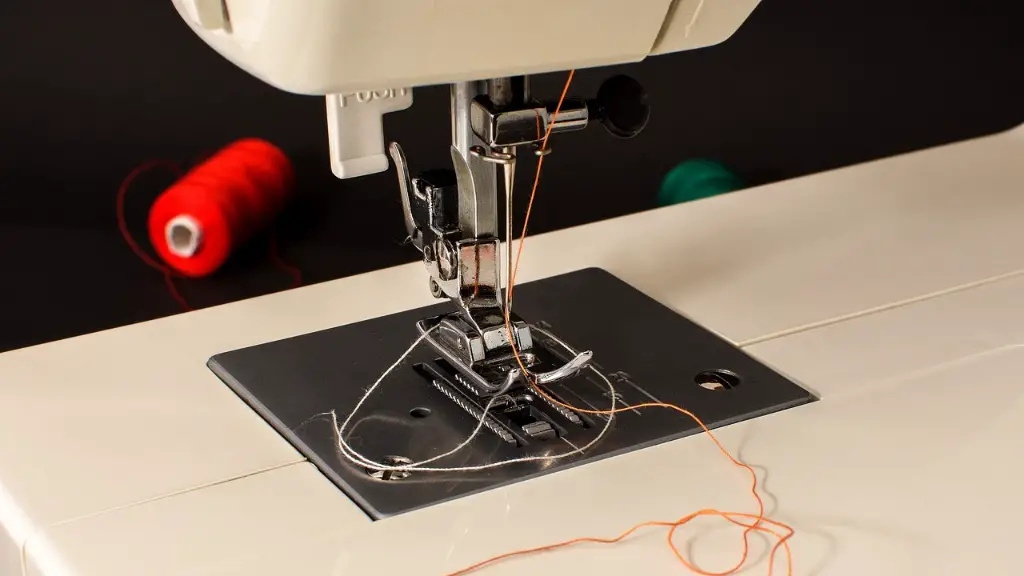

It’s easy to forget to keep your machine clean – but it’s one of the most important things you can do when it comes to reducing tension problems. Lint build-up and idle pieces of fabric can cause tension issues, so it’s important to keep your machine clean. Make sure to regularly clear out the lint tray and clean the bobbin area and needle plate.

Choose the Right Settings

When starting a sewing project, the fabric type, stitch length, and thread type all play a role in tension settings. It’s important to use the right settings for the job. For example, if you’re using a lightweight fabric, use a short stitch length and lightweight thread. If your fabric is too heavy for the thread, the thread has a harder time passing through and that pushes the tension up, leading to frayed edges and other tension problems.

Pre-Stretch the Thread

If your tension is still off no matter what you do, you may have to pre-stretch the thread. To do this, simply pull the thread gently with your fingers and then re-thread the machine. This allows the thread to stretch and reduces tension levels.

Tension Troubleshooting

Sewing machines are delicate devices, and sometimes tension issues can be caused by something out of your control. If adjusting the settings doesn’t work, it’s best to take the machine to a technician for a tune-up. They can check for any mechanical problems that may be causing tension issues.

Change the Needle Regularly

When using your sewing machine often, it’s important to change the needle regularly. Even if you’re using the right needle for the project, constantly pushing it through fabric can cause it to wear out and become dull. This can lead to tension problems, as well as other issues with the stitch and fabric.

Check the Thread Path

To make sure the thread is flowing correctly through the machine, check the thread path. Not all sewing machines are the same, so check the owner’s manual to follow the thread path correctly. All of the thread guides should be accurately in place and the thread should be going through the correct area at each step.

Conclusion

Keeping your sewing tension balanced doesn’t have to be a hassle. With a few adjustments and some regular maintenance, you can keep your sewing machine running smoothly for years to come. Remember to always check the manual before working with the machine, and always use the correct settings for each project.