Threading the Needle on a Sewing Machine

When it comes to sewing, threading the needle on the sewing machine is one of the most important tasks you need to do. If the needle isn’t threaded properly, it can turn a sewing project into a major hassle. Luckily, with a few easy steps, threading the needle on a sewing machine is simple and straightforward.

Before you begin threading the machine, it’s important to make sure that the needle is in the correct position. It will usually be a few millimetres above the level of the presser foot. Then, take the spool of thread and place it at the top of the machine. Pull the thread down toward the needle, passing it through the hole on the needle plate.

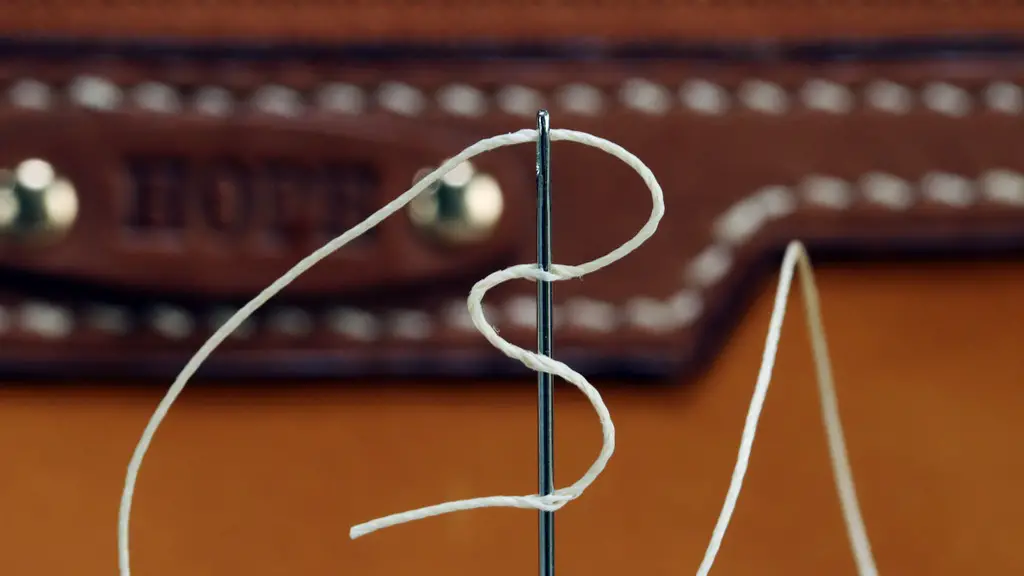

Next, take the thread and wrap it around the take-up lever several times. Then thread the end of the thread through the small hole to the left of the needle. Pull the thread taut and direct it down through the thread guide. From here, you can bring the thread up through the eye of the needle.

Now it’s time to engage the needle. To start, hold the needle up with the thread in it. While doing this, press down on the needle clamp and engage the needle. Release the needle clamp and the needle should now be firmly attached to the sewing machine.

To make sure the needle is engaged correctly, try wobbling it gently with your fingers. If it feels loose in any way, repeat the steps above until it is properly secured. Once it feels nice and secure, your thread should be secured as well.

When you’re threading the needle, don’t forget to insert the thread spindle into the spool pin. This will help the thread flow smoothly through the machine and make threading the needle much easier and faster.

Finally, once your needle is securely engaged, you should raise the presser foot of the machine. This will make it easier to pull the thread through and finish off the threading process.

Testing the Sewing Machine

Now that the needle is secured, it’s crucial that you test the sewing machine to make sure it is working properly. To do this, gently place your finger on the thread near the needle and press the peddle to lift the presser foot. The thread should move smoothly through the machine without any tension.

Once the needle is threading correctly, test the machine on a spare piece of fabric. This will let you know if the thread is placed correctly in the needle, and if the tension and stitch length are set properly. Adjust the tension and stitch length as needed until the stitches look even and consistent, then you can start sewing.

Don’t forget to familiarize yourself with the different stitches and settings. Each stitch will determine the length and tension for your projects. Knowing how to use the different settings and adjust the tension will help you create better-looking, more professional garments and projects.

Tips to Make Sewing Easier

One of the best ways to make threading the needle on a sewing machine easier is to make sure your thread is in good shape. Make sure the thread is properly spooled and doesn’t have any knots or tangles. Invest in a quality thread stand or thread guide as well – this will help to keep the thread in place while you’re threading the needle.

Another good tip is to keep the needle and thread clean. Dust, lint and other debris can make threading the needle difficult and cause knots and tangles in the thread. Taking the time to keep your machine clean will help to make threading the needle faster and easier.

Finally, using a magnifying glass can make threading the needle much easier. A magnifying glass will help you to see the needle and thread better, making it easier to accurately thread the needle.

Replacing the Needle on a Sewing Machine

Eventually, you will need to replace the needle on the sewing machine. Replacing the needle can seem like a daunting task, but it’s actually quite easy. To get started, simply loosen the screw at the top of the needle and remove the old needle. Make sure to note the type of needle and size – this information will come in handy when purchasing a new one.

When it comes to replacing the needle, make sure that you only use needles that are designed specifically for the type of machine you have. Universal needles are not always a good option, as they may not fit properly or may cause damage to the machine. Your best bet is to purchase the same type of needle that was originally used in your machine.

When inserting the needle into the machine, make sure that the flat side of the needle is facing the back of the machine. It’s also important to make sure that the needle is inserted all the way in and tightened securely. If the needle is loose, it can cause stitches to be irregular and result in poor quality results.

Sharpening the Needle on a Sewing Machine

Over time, the needle on a sewing machine can become dull and will need to be sharpened. To sharpen a needle, you will need a special needle sharpener made specifically for sewing machines. Most of these devices have a sharpening stone or a grinding wheel, and they are designed to sharpen the needle quickly and easily.

To sharpen the needle, begin by removing it from the machine and then insert it into the sharpener. Place the sharpener firmly against the needle and turn the sharpener in a circular motion. Make sure to check the needle frequently as you sharpen it, as you don’t want to over sharpen and damage the needle.

Once the needle is sharpened, reinsert it back into the machine and make sure it is secured firmly. Then, test the machine by stitching on a spare piece of fabric – this will let you know if the needle is sharp enough and placed correctly.

Caring for a Sewing Machine

Taking good care of your sewing machine is important for ensuring that it works properly and lasts for a long time. Regular maintenance is important – make sure to clean and lubricate the machine regularly. This will help to keep the machine running smoothly and will reduce the wear and tear of the parts.

Also, be sure to read the instruction manual that came with your machine. It will have valuable information on how to care for the machine and troubleshoot any problems that may arise. It’s also recommended that you keep spare parts, such as needles, on hand just in case you need to replace one.

Finally, when it’s time to replace the needle, always make sure that the needle is the correct size for your machine. Using the wrong type of needle can cause damage to the machine, resulting in costly repairs.

Frequently Asked Questions About Sewing Machines

Many new sewers have questions about how to use and care for a sewing machine. Here are some of the most frequently asked questions, and their answers:

- How often should I thread the needle? Generally, it is recommended that you thread the needle each time you start a new project. This will help to keep the thread free of knots and tangles.

- How often should I replace the needle? It is recommended that you replace the needle every 8-10 hours of sewing.

- How do I know when to sharpen the needle? If the needle start skipping stitches or the thread has to be pulled forcefully through the needle, it’s time to sharpen it.

- How should I store my machine? It’s best to store your machine in a cool, dry place. Temperature and humidity can affect the machine and lead to rust or mold growth.

Threading the needle on a sewing machine is a simple task that can be completed in a few easy steps. With a little practice, you’ll become a pro at threading the needle and be able to start sewing projects quickly and easily.