Singer Sewing Machine repair is a skill that needs to be learned and honed. It is often a frustrating task, since there can be a number of components and problems to work through. However, with some patience and the right tools Singer Sewing Machines can be repaired. This article is intended to help guide you through the process of repairing your Singer Sewing Machine.

Check Troubleshooting Manual for Problems

Firstly, use the troubleshooting manual that came with your machine to identify the most probable cause of the problem. Manuals can often list filter maintenance and lubrication problems as well as troubleshooting any mechanical problems with the machine. If your manual doesn’t indicate the exact issue, you’ll need to proceed further.

Check the Threads and Bobbin Case

A typical issue with a Singer Sewing Machine is the bobbin case getting blocked. The blockage occurs when the bobbin thread winds around the bobbin case which in turn causes the upper thread to pull the bobbin thread up. To check for this, detach the bobbin case and make sure the threads are lying flat. If the threads aren’t laying flat, then the bobbin case needs to be replaced. Care should also be taken to ensure there aren’t any other blockages.

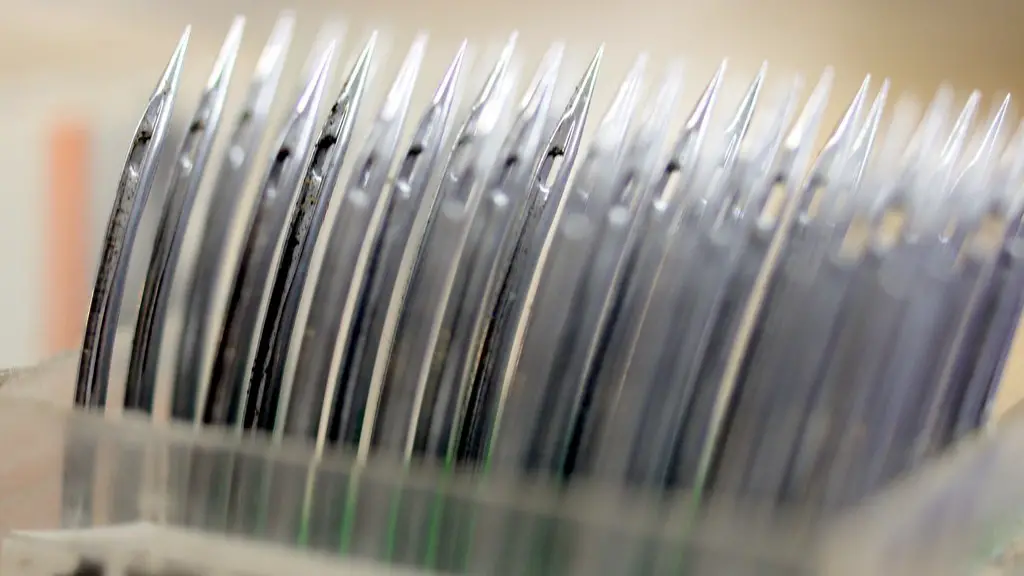

Inspect the Needle and Bobbin

The needle is a crucial component of the Singer Sewing Machine and should be inspected regularly. Make sure the needle is secure and firmly in place as well as being suitable for the fabric you plan to use. In addition, the bobbin needs to be filled properly, winding thread in the correct direction. If the bobbin is not filled properly, the needle will not work properly.

Examine the Belt, Pedal and Motor

Many Singer Sewing Machines rely on a belt to keep the needle moving. Over time, the belt can become stretched and worn out, causing the machine to be unable to sew properly. So it is important to check the belt regularly as well as the pedal and motor for signs of wear. If any parts need to be replaced, it is best to get the replacement parts from a Singer Sewing Machine specialist.

Check the Machine’s Oil and Lubrication

The Singer Sewing Machine needs to be oiled and lubricated regularly in order to keep it running smoothly. To do this, refer to your manual and then use machine oil to fill the oil holes. Make sure to oil every component including the motor, belts, and pulleys. Care should also be taken to ensure the oil is clean and free from contaminants. If the oil is not clean it can damage the machine.

Inspect the Machine for Loose Connections

The Singer Sewing Machine needs to be regularly inspected for any loose connections that may be causing problems. This involves inspecting all the cables, wires and connections for any signs of wear, corrosion or disconnections. Any defective connections should be repaired immediately to avoid potential problems.

Clean and Service the Machine

Finally, a Singer Sewing Machine needs to be regularly serviced to maintain its performance and quality. This involves cleaning the machine and all its components, to remove dust and debris. A good rule of thumb is to change the needle of the machine after every two to three sewing projects. In addition, Singer Sewing Machines should be lubricated and serviced by a qualified technician every twelve months to eighteen months, depending on the amount of usage.

Tension Problems

Tension problems affect all types of sewing machines, including Singer Sewing Machines. It is very important to ensure that thread tensions are properly balanced to ensure an even stitch. To do this, it is important to adjust the upper and lower threads, as well as the bobbin tension. If the upper and lower thread tensions are mismatched this may cause the fabrics to pucker and bunch. A good way to test thread tension is to sew a test swatch and observe the result.

How to Adjust Tension Knob

The tension knob can be located on the front or side of the Singer machine and is used to adjust the tension of the upper thread. To do this, turn the tension knob in either direction until the upper thread laid on the fabric is even and neither too loose nor too tight. It is also important to ensure that the bobbin tension is adjusted correctly as this will influence the tension of the upper thread. If possible, use the same type and weight of thread for both the upper and lower threads.

Check Timing on the Machine

Timing is extremely important on a Singer Sewing Machine. It is necessary to ensure that the needle and the presser foot are properly aligned in order to get even stitches. If the timing is off, there will be irregular or skipped stitches. To keep the timing on a Singer Sewing Machine in check, it is important to regularly check it and make any necessary adjustments. To do this, turn the hand wheel until the needle is at its highest point, then check for the correct timing. If necessary, use the adjustment screw to make any alterations.

Finding and Replacing Parts

When it comes to finding and replacing parts, Singer Sewing Machine parts are highly sought after. It is therefore important to research and find the correct parts for your model of Singer Sewing Machine. To do this, you can look up the model number of your machine and search online for available replacement parts. Alternatively, you can also go to a local Singer Sewing Machine dealer or repair shop who should be able to help you find the right parts.

Asking for Assistance

If all else fails, there is nothing wrong with asking for help. There are lots of experts who specialize in Singer Sewing Machine repair and are happy to help you out. It is best to contact Singer directly who will have trained professionals to help you diagnose and repair your machine. You can also find local sewing machine repair shops and ask them for help.

Replacing the Entire Machine

Repairing a Singer Sewing Machine can often be expensive and time-consuming. If your machine is too old or too damaged to be repaired, or if it’s causing too many problems, then it may be best to replace the whole machine. There are lots of different models of Singer Sewing Machines available on the market, so it’s important to carefully research and consider your options. After all, a good Singer Sewing Machine requires a good investment.

Practicing on Regular Basis

A Singer Sewing Machine is a great tool for any crafter and sewist. However, to get the most out of it and to avoid future problems and repairs, it is important to practice regularly. Try to sew different fabrics and use different types of needles and threads. This will help you to become familiar with the machine and its components. Practicing also helps to identify any problems early on so they can be fixed before they become more serious.