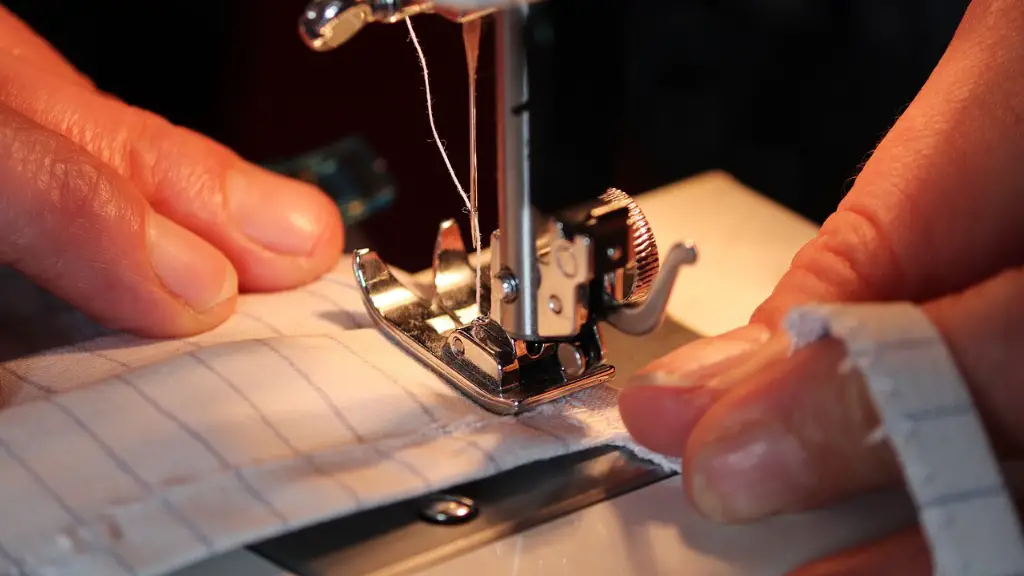

Sewing machines are one of the most commonly used tools in the home, and their needles are constantly in use. Over time, the needles will become dull and will need to be replaced. Here are a few easy steps on how to replace a sewing machine needle.

To replace a sewing machine needle, first remove the old needle by unscrewing the needle clamp with a screwdriver. Insert the new needle into the needle clamp with the flat side facing the back, and tighten the screw to secure it.

Is it easy to replace sewing machine needle?

Sewing machine needles should be replaced when they become dull or break. This is a simple task that will improve your stitch quality. Most sewing machine manuals come with instructions for replacing the needle, but here are the basics: Loosen the needle set screw, pull the needle downwards and out of the needle bar.

To position the needle, turn the hand wheel towards you with your left hand. Hold on to the needle with your right hand.

Are sewing machine needles universal

Sewing machines needles are standardised and are compatible across the range of brands, including Janome, Brother, Husqvarna, Elna, Pfaff etc.

If you want your sewing projects to go smoothly, it’s important to use a sharp needle. Amazing Designs recommends changing your needle at the start of every project, or after about eight hours of sewing. Also, be sure to change your needle whenever it becomes bent, dull or develops a burr. Damaged or worn needles can cause broken or shredded threads, so it’s important to keep your needle in good condition.

What happens when a sewing machine needle breaks?

If your sewing machine needle breaks, it’s important to take care when removing it. It may affect the timing, which means that the machine will not form a stitch correctly. You also need to make sure you recover all parts of the needle because even as tiny as the broken point may be, it can become lodged in the wrong place and keep the working parts of your machine from moving as they should when you sew.

There is no definitive answer to this question since it depends on a variety of factors, such as the type of fabric you are using and the desired outcome of your project. However, as a general rule of thumb, the bigger the size number, the bigger the needle, and the thinner the fabric you are using, the smaller the needle size you will need. Vice versa, for thicker fabrics you will need a larger needle. Ultimately, it is best to experiment with different sizes to see what works best for your particular project.

How do you take the needle out of a singer start?

Using our screwdriver, we’ll turn our screw to the left. And all we need to do is just loosen the screw a bit and it should come right off.

There are two ways to put a needle in a machine, with the flat side or the rounded side facing the back. The flat side is the correct way, as the rounded side should be facing forward.

How do you remove a singer needle plate

To remove the base plate, lift it up at the back and push it backwards. There’s a little lip at the front that you can use to pry it up if needed.

If you are giving someone a shot, it is important to hold the syringe in one hand and pinch up the skin around where you will give the shot. This will help ensure that the needle is inserted at the correct angle. Once the needle is in, let go of the skin and gently push the plunger to inject the medication.

What are the 3 types of needles?

There are a few different types of needles that are commonly used for sewing. The universal needle is a good all-purpose choice for most fabrics. The ballpoint needle is designed to not pierce fabric ends, which can be helpful when working with delicate fabrics. The quilting needle is a good choice for quilting projects. The sharp needle is designed for piercing through tougher fabrics like leather and denim. The topstitching needle is a good choice for topstitching projects. The stretch needle is designed for working with stretchy fabrics.

There are different types of home sewing machine needles, each designed for different types of fabric. The 130/705H system is designed for light to medium weight fabrics. You can see this number on the package, in the picture above.

Do you thread a sewing machine needle from the front or back

To thread a needle, start by pulling your thread down toward the sewing machine needle. Then, thread the eye of the needle from front to back. Keep pulling the end of the thread until there are several inches of thread through the needle.

It is important to change your sewing needle often, as overused needles can cause tugs in your fabric, uneven stitches, and many other common sewing headaches. The average lifespan of a sewing needle is between 6-10 hours, depending on the thickness of the fabric being used.

How can you tell what size needle you should use on your fabric?

Whether you are hand sewing or using a machine, the needle you choose is important. The wrong needle can make sewing difficult, and can even damage your fabric.

Most needle companies show both sizes on the package. A good rule of thumb to keep in mind is: the lighter the fabric the smaller the needle size and the heavier the fabric the larger the needle size. Many times the thread you will be using for your sewing project will also determine the type of needle you choose.

There are different types of needles for different types of fabrics and projects. Below is a list of some of the most common needles and when to use them:

Universal needle: can be used on a variety of fabrics from light to medium weight

Ballpoint needle: use on knit fabrics to prevent runs and snags

Sharps needle: use on delicate fabrics or when you need a precise stitch

Buttonhole needle: use when sewing buttonholes

The type of needle you use is important, but so is the size. Needles come in a variety of sizes, from very fine to very thick. The size you need will depend on the fabric you are using and the type of stitch you want.

When in doubt, it is always best to err

If you find a needle in your animal, it is important to remove it carefully and immediately. Firmly rub your hand over the injection area to locate the needle, and then remove it ensuring that the entire needle is retrieved. If you are unable to remove the needle, seek professional veterinary services immediately.

Warp Up

If your sewing machine needle is bent, dull, or otherwise damaged, you will need to replace it. Replacing a sewing machine needle is a fairly simple process that only requires a few minutes and a few tools. Here is how to replace a sewing machine needle:

1. First, identify the type of needle you will need. There are different types of needles for different types of fabrics and projects.

2. Next, remove the old needle from the sewing machine. To do this, first loosen the needle clamp screw and then carefully pull the needle out of the holder.

3. Insert the new needle into the holder, making sure that the flat side of the needle is facing the back.

4. Tighten the needle clamp screw to secure the needle.

5. Finally, rethread the machine and test it on a scrap piece of fabric before beginning your project.

Thread the new needle that is the same size as the old one onto the machine. Make sure that the needle is facing the correct direction and is inserted all the way. Then, take off the old needle by unscrewing the needle clamp. Finally, screw on the new needle by tightening the needle clamp.