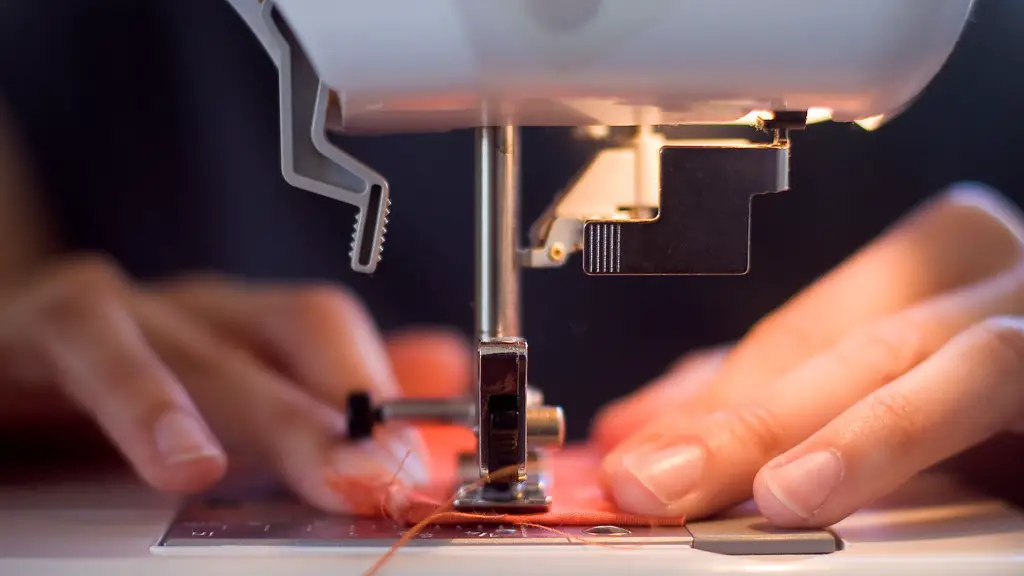

Steps to Replace Needle on Kenmore Sewing Machine

Replacing a needle on a Kenmore sewing machine is an essential part of machine maintenance, and it helps ensure that effective stitching can be made. While needle size and type will vary based on the project and material, replacing it is a relatively simply process once the user understands the basics. Here are some key steps to follow when replacing needles on the Kenmore sewing machine.

Step 1: Before You Begin

Before replacing a needle on the Kenmore sewing machine, it is important to ensure that the needle is compatible with the machine and the project. It is essential to check the needle size and type before starting the process. The needle should be perpendicular to the presser foot when correctly mounted. When in doubt, refer to the manual for the Kenmore sewing machine model.

Step 2: Loosen the Needle Screw

Once the needle is selected, the user will need to loosen the needle screw located in the needle clamp. Before loosening the screw, the user should apply some pressure downwards on the pressure foot. This helps to protect the machine and make sure that the needle does not move unexpectedly during the replacement process.

Step 3: Insert and Tighten the Needle

Once the needle screw is loosened, the user can then insert the new needle into the machine. To do this, they must place the needle in the grip with its long shaft towards the rear of the machine and with its flat side facing the left. The user can then tighten the needle screw until it is secure and the needle is in the correct position.

Step 4: Replacing the Needle Plate

To ensure the needle is securely in place, the user should remove the needle plate and use a small brush to clean the clogged areas. This will help to keep the machine running smoothly. The user should then replace the needle plate securely. This process helps to prevent fabrics from becoming caught during stitching.

Step 5: Test the Needle

Once the needle is changed and the needle plate is replaced, the user should test the needle by stitching some fabric. This helps to check that the needle works correctly and that the fabric is not caught in the machine during stitching. By following these steps, replacing a needle on the Kenmore sewing machine should be relatively straight forward.

Selecting The Right Needle

Needle selection is another essential factor when replacing a needle on the Kenmore sewing machine. Needles come in all different sizes and lengths, and it is important to check and make sure that the correct needle is being used for the project. Some factors to consider when selecting the right needle are the type and weight of the fabric, the thread size, and the type of stitch being used.

Needles also come in various types, such as universal, stretch, denim, and microtex needles. Universal needles are suitable for most fabrics and effects, such as basic stitching and decorative stitching. Stretch needles are designed for highly elastic fabrics and can be used for a variety of fabrics that “stretch”, such as fabric for sports clothing. Denim needles are best for tougher fabrics such as denims, canvas, and heavy twills. Lastly, microtex needles are specially designed to work with delicate fabrics, such as microfiber and polyester.

Not only is it important to select the right type of needle, as it ultimately affects the quality of the stitching, but it is also important to ensure that the needle is suitable for the machine. This is where the manual is essential; it will specify the correct needle size and type for the model.

Using the Correct Needle Size

Depending on the type of fabric, the user will also need to select the correct needle size. The size of a needle is determined by its diameter, with typical sizes ranging from 60 to 110. A larger size needle will penetrate the fabric more easily and produce a stronger stitch. Conversely, a smaller needle will produce a finer stitch on finer fabrics. It is recommended that the weight of the fabric should determine the size of the needle being used.

In general, a needle size of 60 to 70 is appropriate for light fabrics such as satin, silk, taffeta, and chiffon. A size of 80 to 90 is suitable for medium weight fabrics such as cotton, flannel, and batiste. And a needle size of 90 to 110 is appropriate for heavier fabrics such as denim, corduroy, and vinyl.

Other Considerations

When replacing the needle on a Kenmore sewing machine, there are some other factors to consider. It is important to note that needles wear down quickly with use. For example, when stitching multiple thick fabrics, it is recommended to use a higher gauge needle. This is because the needle needs to penetrate the fabric multiple times to form the stitches. As such, it is important to check the needle frequently to make sure that it is in perfect condition and does not need to be replaced.

Lastly, to extend the life of the needle, it is important to use the right pressure when stitching. Too much pressure can cause the needle to warp or break, which could damage the unit and lead to extra costs. Generally, the presser foot should be adjusted to the lowest pressure that produces a good stitch.

Preparing the Cushion and Throat Plate

When replacing a needle on a Kenmore sewing machine, it is important to check that the cushion and throat plate have also been prepared. The cushion ensures that the fabric is held in place and the throat plate prevents the needle from entering the internal parts of the machine. To make sure these components are ready for use, it is important to make sure that the cushion is clean, the throat plate has been oiled, and the presser foot is correctly adjusted.

It is also wise to check if the presser foot is secure. If the foot does not align correctly with the needle, it can cause the fabric to move or become stuck in the machine during stitching. To avoid any issues, it is therefore important to make sure that the presser foot is secured correctly.

Cleaning the Machine

After replacing the needle and preparing the cushion, throat plate, and presser foot, the machine still needs to be cleaned. This is important as wool and fibres can accumulate around the needle, affecting stitching quality. To do this, the user should use a gentle brush and a mild cloth to dust away any loose particles.

It is also important to ensure that the bobbin area is cleaned frequently and oiled when necessary. This helps to reduce any fraying of threads and prevents the machine from becoming obstruction withwool. Additionally, it is important to remove any accumulated lint from the bobbin area. This will help to keep the machine running smoothly.

Keeping Spare Parts on Hand

Having spare parts for the Kenmore sewing machine can be a great asset and help to keep the machine running smoothly. Items such as needles, bobbins, and presser feet can be useful in certain instances and can help to make sure that the project is completed in a timely manner. In this way, it is wise to keep some spare parts on hand in case of emergency.

In terms of needles, it is important to check which type of needle is compatible with the machine model. Additionally, it is wise to keep a variety of needles in different gauges and sizes, as this can help to ensure that the most suitable needle is always at hand.