Hemming is one of the most common sewing techniques and is an essential skill to learn if you want to make your own clothes. Hemming your own clothing is not only an economical choice, but it also allows you to create garments that fit your unique body type. Rolling hems are a great way to finish off a garment with a neat and structured look, but they can be tricky to master. In this article, we will provide step by step instructions on how to roll hem on a sewing machine.

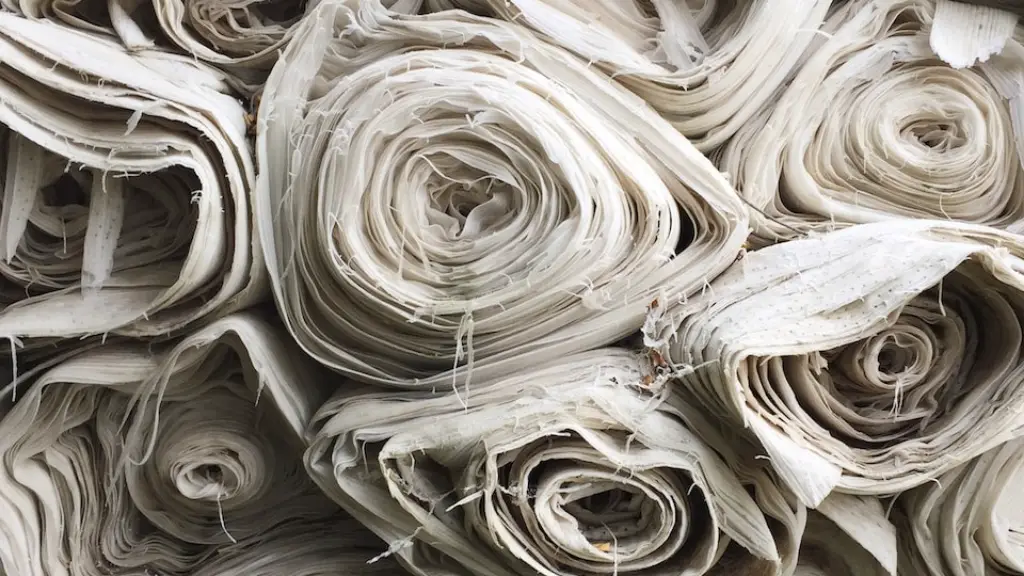

Before you begin, it is important to understand the basics of hemming. Hems are most commonly used to finish off the edge of a garment – holding the fabric in place and keeping it from fraying. Hemming can be done with hand stitching or a sewing machine, and can vary in size depending on fabric weight, style and area hemmed. Rolled hems usually offer a neat and structured look, and are used to provide a clean, professional finish to garments.

When hemming with a sewing machine, it is important to understand the gapping technique. This technique involves setting two lines of stitches that are slightly apart in order to create a ‘tuck’ or ‘gap’ along the hem edge. This process can be achieved with a regular sewing machine, however using a triple stitch function may achieve a neater finish. The triple stitch is a zig zag stitch that passes over the edge of the fabric – the wider the gap between the stitches, the wider the rolled hem.

To create a rolled hem, begin by folding the edge of the fabric over itself at a 1/4 inch seam allowance. Ensure that the fold is as even and straight as possible, as this will help to keep your hem neat and consistent. Once the fold is in place, sew two lines of stitches along the edge of the fold – about a quarter of an inch apart – using the gapping technique mentioned above. Once the hems been stitched, iron the seam to press the fold in place and make sure it is even.

With the bent seam in place and securely sewn, you’re ready to roll the hems. Before you begin, make sure to use narrow double fold bias tape or store-bought hem tape to secure the rolled hems in place. Begin by rolling the hem slightly from the inside of the garment, making sure to keep the fold as even as possible. Once you have finished rolling the hem, use a top stitch to secure the fold, ensuring the stitch is guided between the two lines of gapping stitches. The final step is to secure the rolled hem using the bias tape or hem tape, and then top stitch it in place. This will help to keep your hem in place and add a clean, professional look.

Checking the Finished Hem

Once you have finished rolling the hem and securing it in place, it is important to check the finished product. Make sure that the hem is straight and even, and the stitches are placed correctly and securely. To ensure your rolled hem is secure and even, use a seam ripper to remove any excess fabric or misaligned stitches.

When it comes to rolled hems, practice makes perfect. With some practice and patience, you will soon be able to produce professional looking hems with ease. If you’re having trouble getting the hang of it, there are plenty of online tutorials and sewing classes that will provide helpful tips and advice.

Troubleshooting

If you’re having trouble getting your rolls to look neat and even, there are a few simple techniques that you can use. First, try using a smaller stitch length to make sure the stitches stay in place. You can also try using a wider gap between the gapping stitches to give the fabric more of a rolled effect. Lastly, make sure to use the right fabric and thread type – some fabrics and threads are better suited to rolling hems than others.

Rolled hems are often used to finish off garments with a clean and professional look. To achieve the best results, it is important to make sure that your fabric and thread type are suitable for rolling hems, and that you understand the gapping technique. With some practice and patience, you will soon be able to produce neat and even rolled hems with ease.

Preventing Seam Fraying

Another useful tip when hemming is to make sure the seam allowance is secured properly. This will help to keep the edges of the fabric from fraying during rolling and stitching. To secure the seam allowance, use a small strip of fusible webbing along the fold line. This will help to hold the fabric in place and prevent seam fraying during the rolling process.

Hemming is an essential skill for anyone who wants to make their own clothing. It may take some practice, but with a few simple tips and tricks you can easily master rolling hems. From selecting the right fabric and thread type, to understanding the gapping technique, rolling hems is an art that can add the perfect finishing touch to any garment.

Correct Fabric Length Measurement

Before you start rolling the hem, it is important to ensure that the fabric is the right length. The easiest way to measure fabric length is to use a tape measure. Measure the fabric from the top of the hem to the bottom edge. Do this twice – once along the side and once along the end. If the fabric is too long or too short, you may need to trim it down to the right size. This will help to ensure that your rolled hem is even and neat.

When hemming, it is best to avoid using fabric with an oily finish, as this type of fabric can be more difficult to roll. Additionally, it is important to use the correct thread type and thread size for rolling hems. The thread should be lightweight and of good quality, as this will ensure that the stitches will not break or unravel easily.

Rolling hems is a great way to give your garments a professional and tidy finish. With some patience and practice, you will soon be able to master rolling hems and create garments that fit your unique body type. Remember to use the right fabric and thread type, understand the gapping technique, and to measure the fabric length correctly before you start rolling the hem.

Using the Right Needle Size

When hemming with a sewing machine, it is important to use the right needle size. Choose a needle size that is slightly smaller than the thread size, as this will reduce the risk of thread breakage and help to create a neat and even seam. Additionally, using the right needle size will ensure that the stitches pass through the fabric without ripping the material. Choose a universal or microtex needle for light and medium weight fabrics, or a topstitch needle for heavy fabrics.

Using a twin needle can also be helpful when creating rolled hems. Twin needles are designed to stitch two lines of stitches at the same time, and can help to create neat and even lines of stitches. Using a twin needle may also reduce the risk of thread breakage, and ensure that the stitches stay in place.

When rolling hems on a sewing machine, it is essential to use the right needle size. Choosing a needle size that is slightly smaller than the thread size, can help to reduce the risk of thread breakage and ensure that your rolled hem looks neat and professional. Additionally, twin needles can help to create straight and even lines, and can help to secure the rolled hem in place.

Seam Allowance and Stitch Length

When hemming, it is important to make sure that the stitch length and seam allowance are correct. Depending on the fabric type, a seam allowance of 1/2 to 3/4 inches is recommended. It is also important to choose the right stitch length – standard stitch lengths are between 2.5 to 3.5, however heavier fabrics may require a longer stitch. Additionally, using a wider sensor foot can help to keep the fabric in place while hemming.

When rolling hems with a sewing machine, it is important to make sure that the stitch length, seam allowance and needle size are correct. The correct settings can help to make sure that your hem is neat and even, and will help to prevent thread breakage. Additionally, it is important to use the correct fabric and thread type for roller hems, as this will ensure that the fabric and thread do not move or fray during the stitching process.

Rolling hems is a great way to add a neat and structured finish to any garment. With a few simple tips and techniques, you will soon be able to create professional quality hems with ease. From understanding the gapping technique to selecting the right fabric and thread type, rolling hems is an art that can help to enhance any garment.