Threading a Kenmore Sewing Machine

Threading a sewing machine can be a daunting task, even for experienced sewists. If you are using a Kenmore Sewing Machine Model 158, threading your machine doesn’t have to cause you stress. Today, we will discuss the steps you’ll need to take to thread your Kenmore Model 158 sewing machine.

Steps to Thread the Kenmore Model 158 Sewing Machine

The first step in threading your Kenmore Model 158 sewing machine is to raise the presser foot. To do this, simply lift the presser foot lever located to the left of the machine’s needle. This will allow the presser foot to be raised from the machine’s needle.

The second step is to pull out the thread from the spool of thread and guide it from the spool to the tension discs located at the top of the machine. To do this, use the thread guide located on the top of the machine. This will ensure the thread passes through the tension discs smoothly.

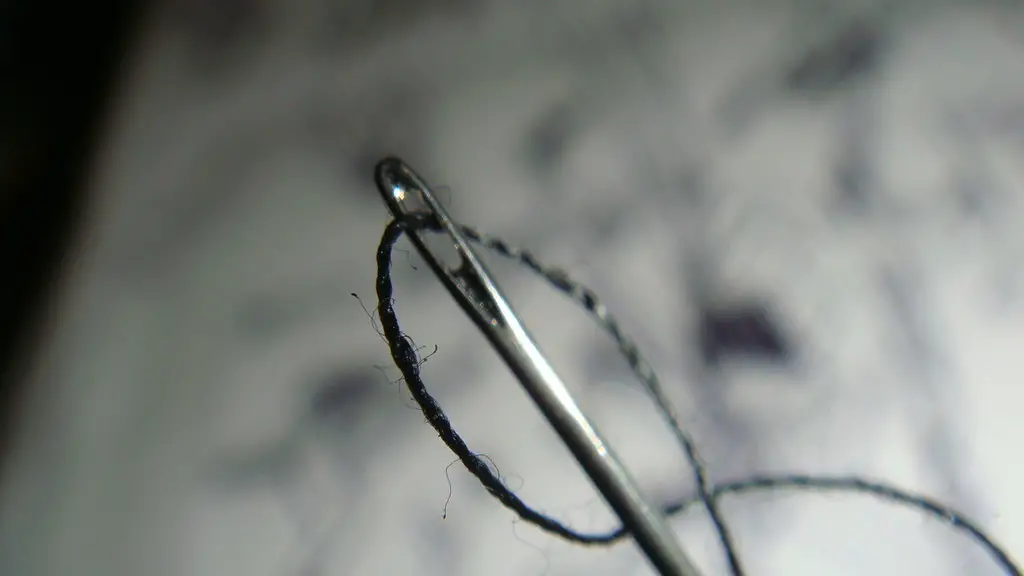

The third step is to thread the needle. To do this, firstly ensure the needle is in its highest position. Then, pass the thread through the needle’s eye and draw the thread taut.

The fourth step is to pass the thread through the thread guides. You can find the thread guides located on either side of the machine. Take the thread and pass it through the guides in the proper order. When you have done this, the thread is nearly ready to go.

The fifth step is to pass the thread through the take-up lever. This is located above the needle. The take-up lever is responsible for taking the thread up through the bobbin case.

The sixth step is to pull the thread through the bobbin case in an anti-clockwise motion and then to the left. This will ensure the thread is correctly threaded through the bobbin case and the needle.

The seventh step is to pass the thread from the needle to the loopers. The loopers help to form the stitches. Ensure you do this step carefully as any misunderstanding of the loopers could result in a messy stitch.

The eighth and final step is to pass the thread through the lower thread guide, presser foot and the needle plate. This will ensure the thread is securely in place.

Changing the Needle

Should you need to change the needle on your Kenmore Model 158 sewing machine, firstly ensure the power is switched off. Then, remove the needle plate by loosening the screw located on the underside of the machine. This will enable you to access the machine’s needle.

Next, remove the old needle and replace it with the new one. Make sure the flat side of the needle is facing away from you when inserting the needle. Reinsert the needle plate, ensuring it is securely in place, and you’re all done.

Maintaining Your Kenmore Model 158 Sewing Machine

To maintain your Kenmore Model 158 sewing machine, start by cleaning the machine after each use. This will help to protect the machine from dust, dirt, and rust. Use a dry paintbrush to sweep away any debris from the machine after each use.

Secondly, oil the moving parts of the machine. To do this, simply use a sewing machine oil, applying both the oil and the grease to the necessary parts. Make sure to use the oil correctly, as using too much oil could damage the machine.

It is also important to keep the needle and presser foot in good condition. If your needle is dull or bent, replace it with a new one. If the presser foot is damaged, it can cause the stitches to be uneven and of poor quality, so make sure to replace it too. Additionally, check the tension discs regularly to make sure the tension is correct.

Identifying Threading Issues

If your thread is not being threaded correctly, it could be caused by many factors. It is important to inspect each of the thread’s path. Firstly inspect the tension discs; if the thread is slipping through them, the tension may be set too low. If the tension is too high, the thread may not be able to pass through the discs.

It is also important to check the needle eye. If it has become too small, it may be necessary to replace the needle. Additionally, the thread guides can become worn over time, so it is important to keep them in good condition. Finally, make sure the thread is wound correctly on the bobbin.

Restoring Your Kenmore Model 158 Sewing Machine

Sometimes your Kenmore Model 158 sewing machine may need more than just a simple repair or maintenance. If your machine needs restoring, it is best to enlist the help of a professional. Always remember that professional repairs for older models of sewing machines may be expensive and time consuming, so be sure to use a reputable service provider.

If you are not sure if your machine needs restoring, there are several signs that can help you identify if this is necessary. The stitching of the machine may become uneven or the machine may become noisy. If your machine starts to produce bad stitches, that is also a sign that it may need restoring.

Troubleshooting Tips

Sometimes threading issues can arise while using your Kenmore Model 158 sewing machine. Firstly, if you are having trouble threading, make sure the thread is correctly wound on the spool of thread. Additionally, if the thread is not being drawn through the tension discs, adjust the tension screw to the correct setting.

If you have completed the threading process but the machine is still not stitching, it could be due to a misaligned presser foot. In this case, you can use a ruler to check that the presser foot is aligned correctly with the needle plate. Finally, if the machine is still not stitching, try adjusting the presser foot pressure.

Keeping Your Kenmore Sewing Machine in Good Working Condition

Now that you know how to thread and maintain your Kenmore sewing machine model 158, it is important to keep up with the necessary maintenance. This will help ensure your machine is in good working condition and that your projects come out perfect every time.

Check for loose screws, clean the bobbin case and oil the moving parts. Be sure to regularly inspect and tighten all parts, as a tighter machine will perform better. Additionally, inspect the needle for bends and nicks as this can cause thread to break or jam the machine.

Lastly, store the machine in a cool, dry place away from direct sunlight. Sunlight can cause the machine to become brittle and faded over time, so make sure to keep it stored in a safe place.