Introduction: An industrial sewing machine is a powerful tool that can make quick and efficient work of a variety of sewing tasks. Threading the machine can seem a daunting task, however, with a few easy steps, you will soon be on your way to sewing. In this article, we will show you how to thread an industrial sewing machine, as well as provide tips to help you get the most out of your machine. Read on to find out all you need to know about threading your industrial sewing machine.

Know Your Machine

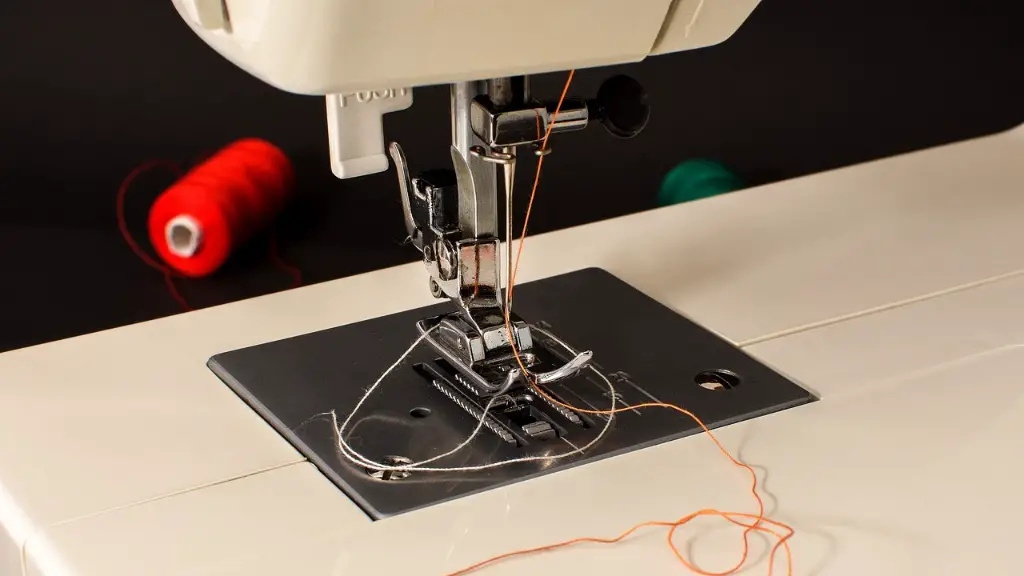

Before you start to thread your industrial sewing machine, it is important to be familiar with the various parts of the machine. For instance, some machines may have a removable needle plate, while others may be equipped with a bobbin winder. Familiarize yourself with the different components, and spend some time familiarizing yourself with how they work.

It is also important to make sure that the machine is properly adjusted. For example, you will want to make sure that the tension is set correctly and that the needle is positioned correctly. Once you are confident that everything is in good working order, you can then proceed to thread the machine.

Threading the Machine

To thread your machine first, lift the presser foot and place the thread in the upper thread guide, located at the side of the machine. Then, pull the thread from the guide and thread it through the take-up lever, then run it under the foot, and finally bring it out the front of the machine. Now the thread can be inserted into the needle from left to right, and any excess thread can be cut.

Next, you will need to prepare the thread for the bobbin. Start by turning the handwheel to make sure the needle is in its lowest position, then open the bobbin case cover. To insert the bobbin, insert the thread onto the two grooves in the bobbin, then place the bobbin in the bobbin case and pull the thread through the small slot. When the thread has been secured, close the bobbin case.

Once the bobbin is correctly inserted and the thread is ready, you can proceed to thread the bobbin. To do this, pull the thread from the bobbin and thread it through the two guides. The thread should then be pulled through the small hole located above the needle plate, and into the tension discs.

Finally, you will need to pull the thread from the bobbin and thread it through the needle from left to right. Then, you can begin to sew.

Tips for Trouble-Free Threading

Threading an industrial sewing machine can be tricky if you are not used to it. Here are some tips to help make the threading process easier:

1. Use good thread: It is important to use high-quality thread that is designed for industrial sewing machines. This will ensure that your thread is strong and smooth, and that it will not snag or break.

2. Replace your needles regularly: A worn-out needle can cause thread to break and jam in the eye of the needle. To prevent this, make sure to replace your needle regularly.

3. Maintain your machine: Like all machines, an industrial sewing machine needs regular maintenance to keep it running smoothly. Make sure to clean and lubricate your machine regularly to keep it running in top condition.

Additional Threading Advice

Threading an industrial sewing machine can be daunting at first, but it is an essential element to a successful sewing project. Here are some additional tips to help you get the most out of your machine:

1. Have the correct tension: The tension of your thread is a crucial part of successful sewing. Make sure that the tension is correct for the fabric you are working with, so that the stitches look even and the fabric does not become stretched or damaged.

2. Familiarize yourself with the settings: Each industrial sewing machine will have its own unique set of settings and features. Familiarize yourself with these so that you can choose the best settings for the job at hand.

3. Read the manual: Most industrial sewing machines come with a detailed manual. Take some time to read the manual carefully and familiarize yourself with its instructions and features.

Solving Threading Problems

Threading an industrial sewing machine can be tricky, and problems may arise. Here are some tips on how to troubleshoot common threading issues:

1. Feed Dog Issues: If the feed dog mechanism is not working correctly, it can cause the thread to snag and break. To fix this issue, make sure the feed dog roller is correctly aligned with the needle plate. If the roller is not lined up correctly, it can cause the thread to be pulled and tangled.

2. Thread Knots: Thread knots can be a frequent occurrence, especially if the tension is not set correctly. To avoid this, make sure that the tension is set properly and that the thread is fed through the guides and tension discs correctly.

3. Bobbin Problems: If the bobbin is not inserted properly, this can lead to threading problems. To make sure the bobbin is properly inserted, check the manual for instructions.

Sticking to Best Practices

Threading an industrial sewing machine can be a tricky process but with a few simple guidelines, you can be sure to get the most out of your machine. Remember to use high-quality thread, replace your needles regularly, and keep your machine well-maintained. Familiarize yourself with the settings and read the manual to make sure you are using the right settings for the job, and take the time to troubleshoot any threading issues that may arise. With these tips in mind, you are sure to get the most out of your industrial sewing machine.