The Basics of Threading a Sewing Machine Bobbin

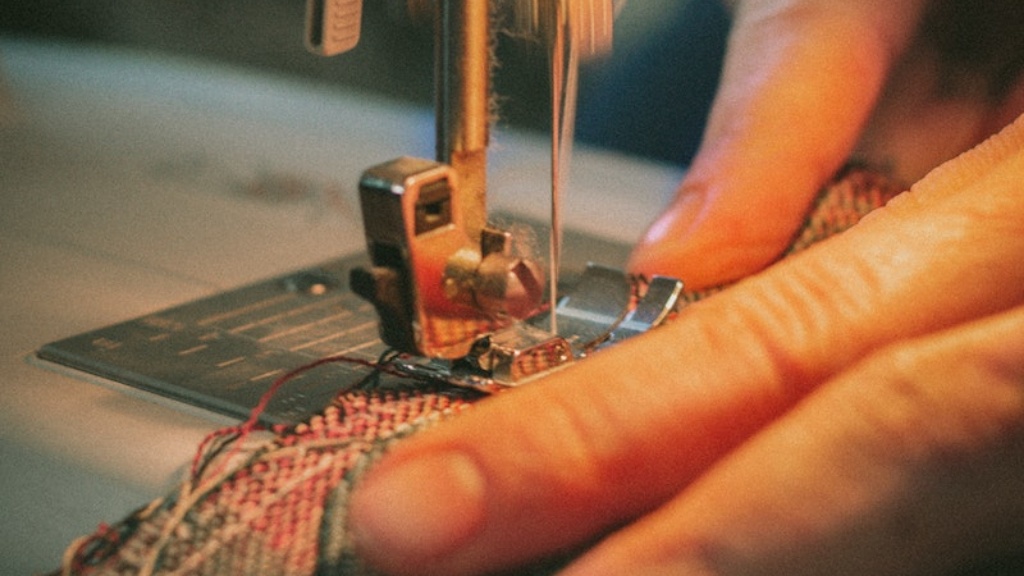

Threading a sewing machine bobbin can often be a tricky task, particularly if you’re new to using a machine, so taking the time to understand the process is essential for creating beautiful, professional-looking stitches. Whether you’re using an old Singer sewing machine model or something more modern, the basic process for threading is similar. Here’s a step-by-step guide to help you learn the basics so you can get started.

First of all, you will need to locate the bobbin and the bobbin race on the machine. The bobbin race is the metal or plastic slot which the bobbin fits into. On most Singer machines, the race is located underneath the needle plate. Once you’ve located this, you can thread the bobbin in the following way.

Start by cutting the thread and then separating one end of the thread from the spool. Next, feed the thread through the bobbin raceway and bring it up through the small thread guide. From here, you can press the bobbin clockwise into the race, making sure that it is properly seated. If necessary, use a screwdriver or other tool to make sure the bobbin is properly tightened in the race.

Then, raise the needle to its highest point using the handwheel on your machine. Keeping the thread raised, pull both the thread from the spool and from the bobbin until there is enough slack from both to wrap the thread together around the take-up lever. This takes-up the tension from the thread and prevents the machine from looping or other issues.

Following this step, you can pass the thread around the bobbin in a clockwise motion, making sure to leave an inch or so of thread un-wound. Then, properly wind up the bobbin clockwise until it is full. Once it’s been fully wound, you can cut the thread and snap it off against the bobbin thread guide. You should be left with a bobbin that is full of thread, ready to be used.

Lubricating Older Singer Sewing Machines

It can be helpful to learn how to lubricate older Singer machines as they can often become stiff due to lack of use or not being serviced regularly. This is important to ensure that when you’re threading the bobbin, the parts are not creaking or sticking which can affect the threads. To lubricate the machine effectively, you’ll need to do the following.

Before starting, have a rag or cloth handy as lubricating the machine can be a messy process. Start by taking off the needle plate and cleaning out any lint or thread debris. Next, using a small amount of lubricant, such as tri-flow or 3-in-1, apply it around the shafts, linkages and pulleys on the machine. Pay particular attention to the bobbin race as this is often a place where lint can gather over time and affect the machine’s performance. Make sure to also lubricate the take-up lever, presser bar, bobbin winder stop and any other areas of the machine which show signs of wear.

With older machines, it’s important to only use a small amount of lubricant, so as not to cause any problems. Allowing too much lubricant can lead to a gummy residue which can then affect the machine’s performance. Finally, use the cloth to wipe away anything which is not required, making sure to clean away any excess oil.

Tension Settings When Threading a Sewing Machine

Getting the tension setting right on your machine is essential when you’re threading a bobbin. If the tension is too tight, the thread can break easily which will result in you needing to start the process again. On the other hand, if the tension is too loose, the stitches will be loose and the quality of results won’t be as good. Thread tension is greatly affected by the types of fabric, threads and needles being used, so it’s important to be aware of these.

Most machines have a numbered dial which you can use to adjust the tension from 0-9, with 0 being the loosest and 9 being the highest tension. For most light to medium-weight fabrics and threads, a tension setting of between 4-5 and for heavier fabrics & threads, a setting of 5-6 should work well. As a general rule, start with a low-tension setting and then if needed, gradually increase until you get the desired results.

It’s also important to note that tension can be affected by other factors, such as humidity, so it may take a few trial and errors to determine the ideal tension setting for the project at hand. The best way to test a tension setting is to sew a piece of scrap fabric and then inspect the stitch quality. If needed, adjust the setting until the stitch looks balanced.

Essential Tips for Threading A Sewing Machine Bobbin

Here are a few other tips to help make sure your threading experience is a smooth and enjoyable one.

- Always use high quality thread and needles. This is especially important when sewing heavier fabrics such as denim.

- Make sure you keep the thread spools away from the machine as friction can break the thread.

- Test the tension before sewing your project, making sure the stitch is even and not too tight or loose.

- Always read the instruction manual that came with your machine, which should have specific instructions for threading.

- Lubricate the machine regularly in order to prevent any sticking or creaky parts.

- If you’re really struggling, consider asking an experienced family member, friend, or mentor for help.

Choosing The Right Thread For Your Bobbin

Having the right thread for the project you are working on is very important. The type of thread you choose will depend on a number of factors, such as the fabric you are using, the type of stitching you need, and the look you’re trying to achieve. Most threads come in a range of sizes, from quite thin to quite thick, and there are many types of varieties, such as cotton, polyester, and even speciality threads such as metallics. As a general rule, it’s best to choose a thread that is the same weight as or slightly thicker than the fabric that you are working on.

A good way to test the right thread is to do a test sample. Cut a piece of fabric of the same weight as the one you’re using, and then sew a few stitches with the chosen thread. This will help you determine whether the chosen thread is the right one for the job. For example, if the chosen thread is too thick, the stitch may be too bulky. You may need to experiment a bit until you find the perfect thread match.

Choosing The Right Needles For Threading

Similar to selecting the right thread, it is just as important to make sure you select the proper needle for the fabric you are using. Needles come in all different types and sizes, and selecting the wrong needle can result in skipped stitches and even damage to the fabric. Most needles are labelled with their size and type, which is the best guide to follow. The type of needle you use will also depend on the fabric, such as if you are sewing a delicate fabric then you will need a finer needle compared to if you are working with a heavier material, in which case a thicker needle may be more suitable.

As a general rule, all needles should be regularly changed. This is because they become blunt and worn over time, which can affect the stitch quality and performance of the machine. Also, a worn or broken needle can become dangerous, so it’s important to remove and replace the needle with a new one when needed.

Repairs and Maintenance of a Singer Sewing Machine

If you own an older Singer sewing machine, it is important to be aware that you may need to service and repair it from time to time in order to keep it running as smoothly as possible. Oftentimes it may be necessary to take the machine in for repairs or to ask a professional for help if it is out of your area of expertise. Note that some repairs may be required in order to preserve the warranty of the machine.

For general maintenance or repairs, you may need to remove the needle plate, tension disk, thread guides, and other moving parts in order to get proper access. You may also need to oil the machine in order to keep it running smoothly. And if you’re facing any technical problems with the machine, it’s always best to turn it off and seek the help of a professional.

In any case, it is important to read the instruction manual that came with your machine in order to be familiar with the maintenance and repairs processes in place. This document can provide information about relevant parts, as well as any special techniques and techniques that need to be followed. It can also provide helpful advice and tips for troubleshooting technical issues you may come across.

Summary

Threading a bobbin on an old Singer sewing machine can sometimes be challenging, but by following the steps outlined here, you can make sure you get the best results. From locating the bobbin race, to winding the thread and getting the tension setting right, taking the time to understand the process is essential for creating beautiful, professional-looking stitches. Finally, make sure to clean, lubricate and maintain the machine regularly to ensure it runs optimally when threading the bobbin.