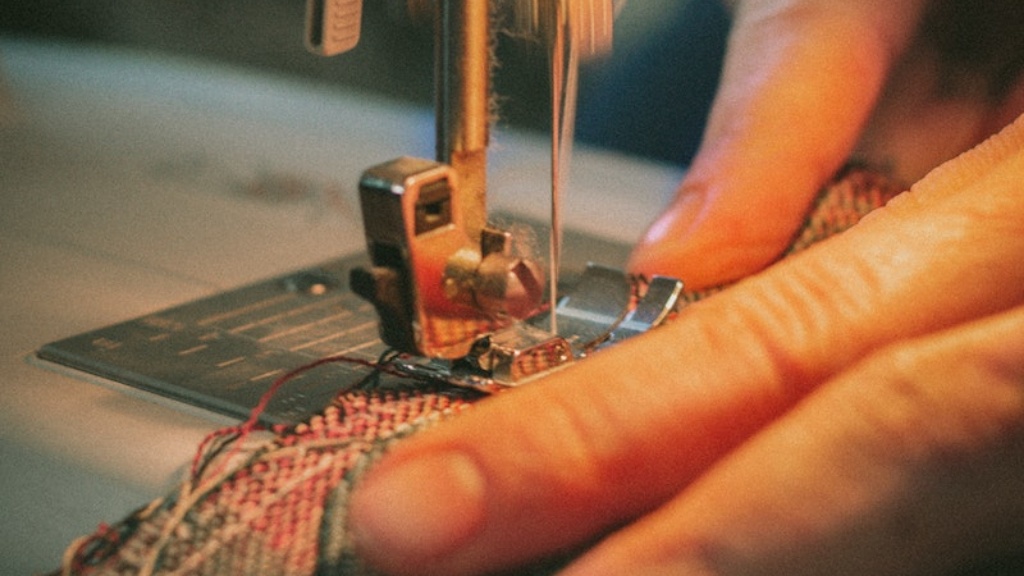

If your sewing machine is having difficulty sewing through the fabric, there are a few potential reasons why. The needle may be too blunt, the presser foot may not be down, the tension may be off, or the fabric itself may be too thick. Once you identify the problem, it should be relatively easy to fix.

Some fabrics are too thick for a regular sewing machine needle to penetrate. You can try using a needle designed for thicker fabrics, or a needle designed specifically for the type of fabric you’re working with. If neither of those options works, you may need to use a different sewing machine altogether.

Why is my sewing machine thread not going through fabric?

If you’re having trouble with your sewing machine, there are a few probable causes. Top or bobbin thread has not been set correctly, the thread does not match the needle, or thread tension is not properly set. Double check your machine’s settings and try again.

If you’re having trouble getting your fabric to feed properly, make sure that the presser foot lifter is lowered before you start sewing. Once you’ve lowered the presser foot, you should be able to continue sewing without any issues.

How do you sew through thick layers of fabric

Clips are a great way to secure fabric while you’re working on it. They come in a variety of sizes, so you can find the right size for your project. Make sure you’re using the right size needle for thicker fabrics or you may have trouble getting the clip through the fabric.

The dial settings on a sewing machine typically range from 0 to 9, with 45 being the “default” position for sewing with straight stitches. This setting should be suitable for most fabrics. If you are working with a particularly thick or delicate fabric, you may need to adjust the dial to a higher or lower setting.

Why is it difficult to pass the thread through?

If the thread is thicker than the size of the hole of the needle, it will be difficult to pass the thread through the eye of the needle. Even if you have normal eyesight, it can be challenging to thread a needle with a thick thread.

If your sewing machine starts to jam, there are a few things you can try to fix the issue. First, check to see if the thread is tangled or the fabric is not being fed evenly. You can also try to clear any lint or dust that may be build-up in the machine. If the needle is hitting something inside the machine, this could also be causing the jam. Always be mindful of the needle while sewing to avoid any accidents.

What is the most common problem when a machine doesn’t sew correctly?

Sewing can be enjoyable, but it can also be frustrating when things don’t go right. Some common sewing problems are:

* Needle thread breakage

* Bobbin or looper thread breakage

* Thread fusing when the machine stops.

If you’re having trouble with your sewing, don’t despair! There are often simple solutions to these common problems.

Bird nesting can be a real pain, especially if it happens frequently. It can cause your fabric to become tangled and even tear holes in your garment. If you’re having trouble with bird nesting, make sure to adjust your stitch length and tension. You may also need to change your needle. If all else fails, bring your sewing machine in for a tune-up.

How do I adjust the feed dogs on my sewing machine

The little button mentioned is most likely the power button, located on the back of the computer near the center. Pressing this button will turn the machine on.

A tension of 35 to 45 is recommended when stitching thick fabric, such as denim or leather. This is to sew through the fabric and maintain neatness throughout easily.

How do you adjust a presser foot for thick fabric?

The presser foot lever can be raised to two different positions. The first position is for when the fabric does not fit under the presser foot. For example, when sewing together thick fabrics, raise the presser foot lever to its highest position so that the fabric can be placed under the presser foot. The second position is for when the fabric is too thick to fit under the presser foot and needs to be repositioned.

The presser foot pressure refers to the amount of pressure that the presser foot applies to the fabric. The pressure can be adjusted to one of four levels, with 1 being the lightest pressure and 4 being the heaviest pressure. For thick fabrics, it is best to use a pressure of 1 or 2, and for thinner fabrics, it is best to use a pressure of 3 or 4.

How do I know if my bobbin tension is correct

Swiftly pull up on the thread. The thread should unwind just slightly and the bobbin case should drop an inch or two. If the thread unwinds without resistance and the case slips to the floor, your bobbin tension is too loose. If the bobbin case doesn’t budge, your bobbin tension is too tight.

Proper bobbin tension is essential to good embroidery. If tension is too tight, unwanted bobbin thread may begin to show on top of your garment and you may begin to experience frequent thread breaks which wastes time and money. Bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps).

When should I adjust the bobbin tension?

The bobbin case is the part of the sewing machine that holds the bobbin. The bobbin is the small cylindrical piece of metal or plastic that holds the thread. The tension on the bobbin case controls the amount of tension on the thread. If the tension is too tight, the thread will break. If the tension is too loose, the stitches will be loose and the fabric will pucker.

If the tension on your sewing machine isn’t perfect, you can fix it by adjusting the bobbin spring. If the bobbin thread is showing on the upper layer, you should tighten the spring. If the needle thread is showing on the underlayer, you should loosen the spring. Test the tension by making another seam and examining the stitches. Repeat this process until the stitch is balanced.

How do you get thread through

There’s no need to beperfection when it comes to needle placement on your fabric. If the fabric is bunching up, simply place the needle over the top of the bunch and continue sewing. More important than beingperfect is being consistent with your spacing and tension.

The droplet of water works like a magnet to draw the thread through the eye of the needle. This is a quick and easy way to thread a needle without having to use a threader.

Conclusion

There are several possible reasons why your sewing machine cannot sew through the fabric. The most common reason is that the needle is not properly inserted into the fabric. Another possibility is that the needle is blunt or damaged. Finally, the tension of the thread may be too tight, preventing the needle from penetrating the fabric.

The most likely reason your sewing machine cannot sew through the fabric is that the needle is not properly inserted. The needle needs to be inserted all the way into the sewing machine for it to work properly. If the needle is not all the way in, the machine will not be able to sew through the fabric.