When to Thread a Sewing Machine

Knowing when to thread your sewing machine is essential for any budding seamstress. Many people don’t realize that proper threading may be the difference between a successful sewing project and an unsuccessful one. A sewing machine needs to be threaded properly in order to produce the desired stitch quality, so it’s important to make sure you know the basics of threading a machine.

Before Threading the Bobbin

Before starting to thread a bobbin on a sewing machine, check that all parts of the sewing machine are in good working order. Make sure the machine is plugged in and on before proceeding, and that the presser foot is down. You should also check the tension on the machine to make sure it is correctly adjusted. It’s also important to check that the bobbin being used is the same type as the machine being used.

How to Thread a Bobbin

Threading a bobbin on a sewing machine is easy, but there are a few steps that should be followed for proper threading. Begin by removing the empty bobbin from the machine, and threading a thread through the eye of the bobbin. Then, place the bobbin on the bobbin winder, and place the thread through the slots of the bobbin winder. Next, press the foot pedal to wind the thread onto the bobbin. Once complete, cut the thread and remove the bobbin from the winder.

Inserting the Bobbin Into the Machine

Once the bobbin has been threaded, it’s time to insert it into the machine. It is important to insert the bobbin the correct way. Depending on the model of the machine, the bobbin will usually be inserted with the thread being pulled up and away from the machine. Place the bobbin in the bobbin case, ensuring the thread is coming from the top of the bobbin. Then slide the bobbin case into the machine from the back side and make sure it is firmly in place.

Threading the Machine

The last step of threading a sewing machine is threading the machine itself. Begin by threading the machine with a thread of the desired color. With the machine’s needle threaded, place the thread through the right-hand thread guide, over the left-hand thread guide, and under the tension slider spring. Then, wind the thread around the take-up lever, located on the top of the sewing machine, and slide the thread under the presser foot before cutting the thread.

Checking the Thread Tension

Once your sewing machine is correctly threaded, it is important to check the thread tension. Thread tension determines how the fabric and thread will interact with each other during the stitching process and should be checked periodically. To check the tension, you can use a simple test. Take two pieces of similar fabric, such as two pieces of muslin, and stitch a few stitches on each piece. Ensure that the threads are equally spaced, that the fabric is not puckering, and that the threads are following the fabric’s edge.

Knowing the Machine’s Settings

Knowing your sewing machine’s settings is key to achieving the desired stitch patterns. Different settings will result in different stitch patterns, and it is important to be aware of all the stitch options before sewing. Be sure to check the manual of the machine to familiarize yourself with all the features and settings of your machine, as some machines have settings that allow the user to customize their stitch patterns.

Making Adjustments

Should adjustments need to be made to the thread tension, presser foot, stitch length, or any other settings, changing them should be done before beginning to sew. After adjusting the settings, it’s important to check that the stitches appear as desired. If not, further adjustments may be necessary to achieve the desired outcome.

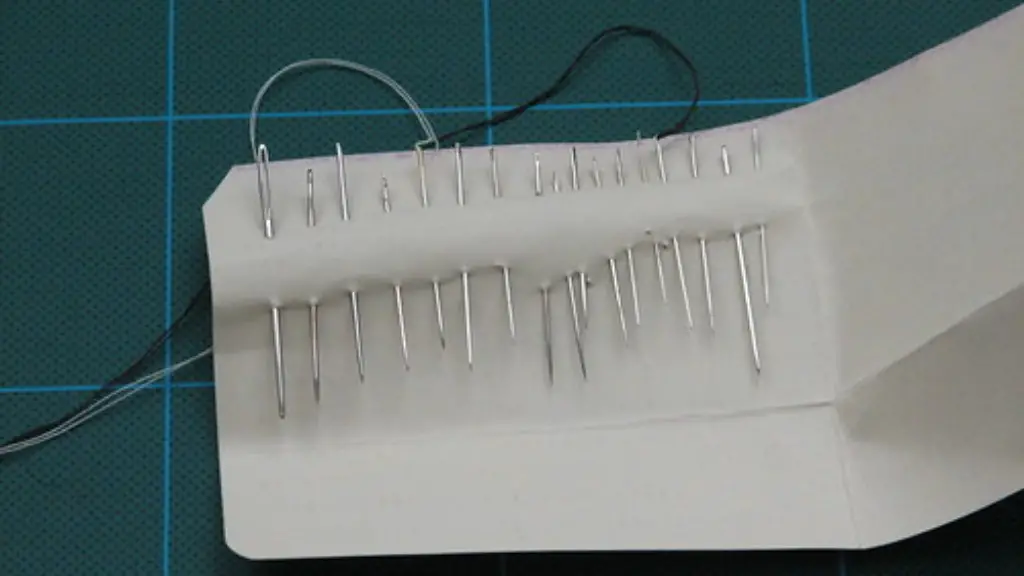

Selecting the Right Needle

Before threading the bobbin of the sewing machine, it is equally important to select the right needle. A variety of needles are available, so it is important to select the right needle type and size to achieve the desired outcome. Needles come in a range of sizes, such as 65/9 or 90/14, and different fabrics will require different sizes. Additionally, different fabrics will require different needle types, such as a ballpoint or a stretch needle.

Securing the Thread

Once the bobbin has been threaded on a sewing machine, it is important to securely attach the thread. To do this, twist the thread around the spool pin a few times and secure it with the spool cap. It’s also important to make it a habit to secure the thread after winding the bobbin and before inserting it into the machine. This will ensure that the thread does not get tangled during the stitching process.

Maintaining the Sewing Machine

Regularly maintaining a sewing machine is essential to keeping it running smoothly and ensuring it produces high-quality stitches. Clean out the lint and dust that accumulates around the bobbin case and make sure the needles are sharp and in good condition. Additionally, it’s also important to lubricate the bobbin case and other moving parts of the sewing machine regularly to ensure it is running smoothly and to prevent it from becoming damaged.

Alternative Threading Methods

While the steps to thread a bobbin on a sewing machine remain the same, there may be alternative methods that some machines require. It is important to carefully follow the instructions in the machine’s manual, as these may differ from machine to machine. Additionally, many sewing machines now have an automatic threading feature that eliminates the need for manual threading.

Synthetic Threads

When threading a bobbin, it is important to ensure that the correct type of thread is used for the fabric being sewn. The majority of fabrics require cotton or a cotton-polyester blend, however more delicate fabrics may require synthetic thread. Synthetic threads are typically stronger and offer more resistance to moisture and heat than traditional cotton threads, so they are a great choice for sewing delicate fabrics.

Tips to Keep in Mind

Threading a bobbin can be a daunting task, but it doesn’t have to be. Following the steps outlined above will ensure that your bobbin is threaded correctly. Additionally, taking the time to check the tension, needles, and other settings on the machine before beginning to sew will make a huge difference in the final outcome of your project. Lastly, make sure to keep the machine clean, lubricated, and in good working order to ensure it continues to produce high-quality stitches.