Preparation

Using a sewing machine to sew fabric can be a rewarding and creative experience. It requires a certain level of patience and practice, but with the right tools and tactics, it can be relatively simple to learn and master. Before beginning, you will want to find an appropriate location and make sure you have a large, well lit work surface. You’ll also want to make sure that you have all the necessary supplies, like needles, thread, scissors, measuring tape, fabric, and other materials for whatever sewing project you are embarking on.

Threading a Sewing Machine

After all the materials have been gathered, the first step in using a sewing machine is the threading. In order to get the machine ready for stitching, the thread must be loaded into the tension disk, bobbin, and the needle. To start threading, take the thread and pass it through the tension disk in a direction that aligns with the numbers, which will vary depending on the type of thread and fabric being used. After the tension disk is threaded, it should be passed through the thread guide located on the back of the machine’s arm. Then, guide the lower thread—the bobbin thread—through the bobbin case and up through the specific slot designed for it. To finish, slip the needle onto the needle holder and thread it through the hole located at the top of the arm.

Using the Proper Sewing Foot

When selecting the type of foot to use for fabric, it is essential to consider the type of stitching that will be done. Different types of feet are best suited for particular stitching. For example, the ¼” foot is best used for precision sewing; the satin stitch foot is made to sew delicate fabrics with decorative stitches; the blind stitch foot is designed to help sew blind hems, etc. The correct foot will allow users to effortlessly and accurately sew fabrics together as needed without any unnecessary stress and mishaps.

Wind the Bobbin

To wind the bobbin, first remove the regular presser foot and attach the bobbin winder shuttle. Then, follow the bobbin stabilization guide located near the shuttle, and lift the presser foot and release the bobbin. Once the bobbin is evenly wound, release the bobbin winder and move the lever back to its original resting place.

Adjust the Stitch Width and Length

Next, adjust the stitch width and stitch length as desired on the machine. Keep in mind that some technics, like decorative stitching, will require a constant stitch length. Also, it is important to ensure that the needle is matching the stitch width selected so that the stitches match up properly.

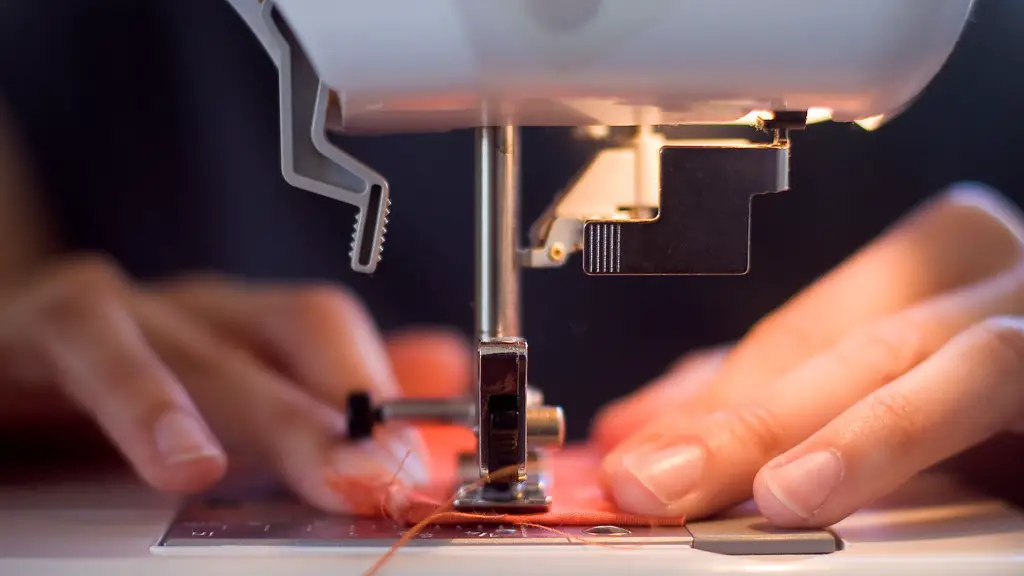

The Sewing Motion

When beginning to sew, the first step is to make sure that the needle thread is tensioned. To do this, press the needle up/down button and lower the needle into the fabric. It is important to position the fabric so that both the top thread and bottom thread are in the fabric’s seams to ensure accurate stitching work. As the fabric moves, hold the top thread and the bottom thread in the seam of the fabric to make sure they are correctly tensioned. Then make sure that the pressure foot is down and pull the fabric back a few times until the stitches become engaged. Finally, begin the sewing motion from this point and begin side-to-side motion to ensure even stitches.

Troubleshooting

Occasionally, sewers may encounter issues like skipped stitches, incorrect thread tension, or stitch length inconsistencies. If this happens, make sure to check for any abnormally frayed or knotted thread, remove any unnecessary bulk from the seams, and rethread the machine as needed. It is also important to check the needle; if it’s bent, replace it with a new one with the proper size and type.

Maintaining and Cleaning the Sewing Machine

Regular maintenance and cleaning of the machine can help to extend its service life. To clean the sewing machine, it is recommended to use a lint brush and/or a special cleaning liquid designed for machines. Regular dusting and wiping-off should be done as needed, and any excess lint should be removed from the shuttle area of the machine. It is also recommended to oil the parts of the machine at least once a year to ensure the optimal performance of the machine.

Safety Tips

When using a sewing machine, there are some safety considerations that should always be taken into account. Always wear protective gear such as goggles or gloves when handling a sewing machine or fabric to protect your eyes and hands. Do not overfill the fabric feeder or attempt to cut or force the fabric through the machine. Additionally, never leave a machine unattended or run a sleeve or hem through a sewing machine without restraining the fabric. Finally, make sure to unload a machine before attempting to move or transport it.

Selecting the Appropriate Presser Foot

When selecting a presser foot, one should consider the type and weight of the fabric that will be used. Each foot is designed for a specific type of fabric and can help to create the desired finish. For example, the mini walking foot is designed for light to medium weight fabrics such as cotton and Jersey knit fabrics, while the lingerie foot is designed specifically for lingerie fabrics such as silk and satin. Additionally, the universal foot is designed to go over and stitch numerous types of fabric, making it a great all-purpose presser foot.

Changing and Installing the Needle

When changing needles, users should always consider the type and weight of the fabric and thread being used. Different needles are designed for a certain type of thread and fabric. To install a needle, first, release the pressure foot by pressing the needle up/down button. Then, unscrew the screw on the holder and insert the new needle. Once the new needle is in place, screw the holder back on. Finally, lower the pressure foot by pressing the needle up/down button once more.

Using the Right Thread

One of the most important aspects of using a sewing machine is making sure to select the right type of thread for the fabric being used. It is important to pay attention to the type of thread being used and make sure it is designed for the type of fabric being sewn. This is especially important when working with fabrics such as silk, linen, cotton, and synthetics, as the thread must be able to withstand the force of a machine and hold the seams together. Additionally, when selecting the type of thread, make sure there is a good contrast between the thread color and fabric color for the best-looking outcome.