Assembly & Operating Instructions

It is important to become familiar with your hand-held sewing machine before beginning any project. To do this you should obtain the machine’s instruction manual from the manufacturer, if it is available. Additionally, you should consult the assembly and operating instructions provided with the sewing machine. Doing so will ensure that you know how to properly assemble the machine, how to thread it, set stitch length, select the correct pressure foot, and how to use the presser foot.

Attachments & Accessories

Hand-held sewing machines come with a variety of accessories and attachments to help make your sewing projects easier. Many models come with a variety of presser foot attachments, letting you sew gathers, pleats, cuffs, and zippers, as well as buttons and snaps. Additionally, most models come with a range of specialty feet, such as a roller foot, specialized zigzag feet, and ruffling feet. Other attachments, such as a bias tape binding or seam guide, may also come with the machine.

Fabric Selection

In order for your project to turn out well, it is important to choose the right material to use. When selecting fabric, you should consider the type of fabric, its weight, and whether it is woven or knit. Each type of fabric requires different needle sizes, thread tensions, and stitch lengths, so it is important to take these factors into consideration. If you are unsure of which type of fabric to choose, a good rule of thumb is to start with lightweight fabrics and move up in terms of complexity.

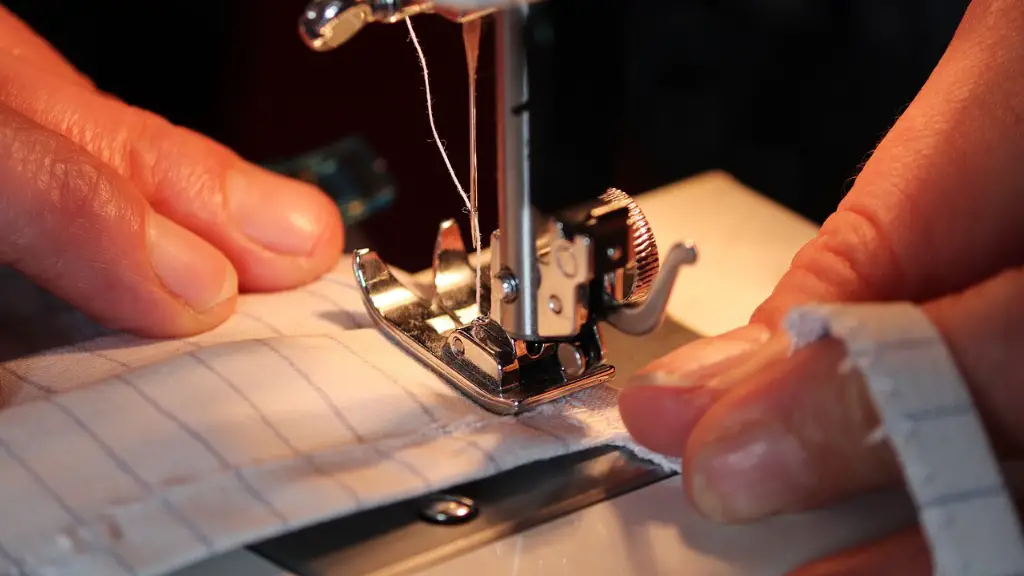

Threading the Machine

Threading the machine correctly is essential to avoid skipped stitches or other sewing problems. The thread spool should be placed correctly onto the thread spindle and the thread should then be pulled through the tension disk and guide plates. Depending on the model, you may then have to pull the thread through one or two more guides before reaching the needle. Finally, the thread must be carefully placed through the needle’s eye.

Stitch Selection

Selecting the correct stitch for each project is key to ensuring success. Most hand held sewing machines offer several different stitches, from basic straight and zigzag stitches, to more complex stitches like buttonhole stitches and blind hemming. Your sewing machine’s instruction manual should explain each stitch’s purpose and how to select it. Generally speaking, for fabric construction, straight and zigzag stitches are the most common.

Stitch Length & Pressure Foot

It is important to adjust the stitch length and pressure foot of the sewing machine before beginning a project. The stitch length should be adjusted depending on the type of fabric and thread you are using. Generally speaking, heavier fabrics like denim require a shorter stitch length, while lightweight fabrics like cotton require a longer stitch length. Additionally, the pressure foot should be adjusted to accommodate the chosen stitch type and fabric.

Operation & Maintenance

To properly operate a hand-held sewing machine, it is important to read and understand the instruction manual. Additionally, always ensure that the machine is plugged into a ground outlet and that it is securely attached to the work surface. When operating the machine, ensure that all controls are in the correct position, and always use the recommended foot pressure and stitch speed. Additionally, to ensure that the machine runs smoothly, it is important to regularly oil and clean the parts, as well as replace the needle when needed.

Network Manufacturing

Network Manufacturing is rapidly becoming a popular method of production. It involves creating localized fabrication systems which are connected through the Internet and are triggered by signals from the end user. Such signals include design files, production data, buyers’ preferences, and so on. This is advantageous because it allows for smaller production runs, it is more cost-effective than mass production, and it has the potential to reduce waste. Additionally, it lowers the entry cost for factories and enables them to produce customized products for customers.

Automated Sewing Machines

Automated sewing machines are becoming increasingly prevalent in the industry. These are machines that can be programmed to carry out specific motions, such as reinforcing decorative stitches, topstitching, and edge stitching. Additionally, they can produce various stitch types, such as zigzag, straight, and blind hem, in a variety of sizes and shapes. Automated sewing machines are advantageous because they are more efficient than manual machines, they are very consistent, and they can reduce fabric waste.

Advancement of Sewing Technology

The advancement of sewing technology in recent years has opened up a whole new world of possibilities in the industry. New machines, software applications, and automation systems have drastically changed the way the industry operates. Additionally, 3D printing has enabled manufacturers to create highly detailed patterns for apparel with unprecedented accuracy. Due to these advances, the production cycle has become much faster, more efficient, and more cost-effective.

Smart Materials & Connected Apparel

Smart materials and connected apparel are emerging technologies that are becoming increasingly important in the industry. Smart materials are fabrics that can communicate with the wearer and their environment, and connected apparel is clothing that is connected via sensors to a smartphone or computer. These technologies are advantageous because they allow the wearer to track their clothing’s performance, detect any health issues, and provide a personalized experience.

Tablet & Phone Based Design Software

Tablet and phone based design software is being developed to make creating patterns and designs easier than ever before. Such software enables designers to create patterns with a tablet or phone, and then share them with manufacturing partners and factories. Additionally, design and fit data can be gathered from customers and used to customize the products accordingly. This is advantageous because it enables designers to create new designs quickly and efficiently, and allows for real-time feedback and collaboration.