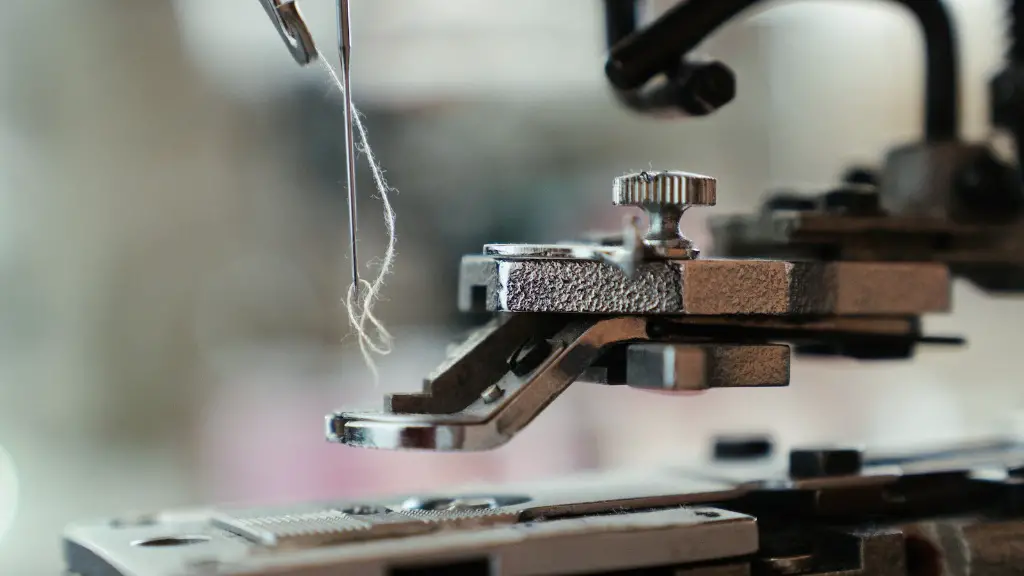

A low shank sewing machine is a type of home sewing machine, which is generally used with the most common shoes and zippers, buttons and seams. Low shank sewing machines are lightweight and compact, making them portable, as they can be easily taken with you while travelling. Low shank sewing machines have a single lever that is used to control the needle thread tension and the fabric feed as well.

These machines tend to be fairly inexpensive and are ideal for a beginner or occasional sewer looking for a starter model sewing machine. Some of the more advanced low shank sewing machines have more sophisticated features, such as electronic controls, allowing for a more consistent stitch quality. Low shank machines can be used for a variety of projects, from basic repairs to complex embroidery.

According to experts, the main advantage of low shank sewing machines is that they are easy to use and can handle a variety of fabrics, including silk and cotton as well as heavier material such as wool, corduroy and jeans. This makes them versatile and perfect for beginners who don’t want to invest too much money in a more expensive, complicated sewing machine.

Although low shank sewing machines are quite simple to operate and are often favoured by novice seamstresses, they can still lead to some issues. For instance, the smaller size can make it difficult to maneuver around and through larger materials, making it harder to sew consistently. Additionally, the tension settings of a low shank machine can be difficult to adjust, making it important to consult a professional to ensure that the tension is correctly adjusted before starting a project.

Low shank machines can also lack power, due to the small motor size. This can be a problem when sewing through heavier fabrics but can be mitigated by choosing a more powerful model. It is also important to make sure that the machine is in good repair before beginning a project to ensure optimum performance.

Overall, low shank sewing machines are perfect for beginners who are looking for an affordable, low-maintenance sewing machine. They are also a great option for more experienced seamstresses who need a lightweight, portable machine for small scale projects.

Pros and Cons of Low Shank Sewing Machines

Low shank sewing machines offer several advantages. They are easy to use and typically very affordable, making them an ideal option for novice sewers who want to learn the basics of machine sewing. They also have a fairly small and lightweight design, making them portable and ideal for smaller projects.

A common disadvantage of low shank sewing machines is that they can lack power. This can be a problem when sewing through heavy fabrics and make sure that the tension settings are adjusted before starting a project. Additionally, these machines can be tricky to maneuver around, making it harder to sew consistently.

What kind of Project is Best for a Low Shank Sewing Machine?

Low shank sewing machines are typically best for small projects such as repairs and simple alterations, as well as basic embroidery. These machines can handle a variety of fabrics, including silk and cotton, as well as heavier materials such as wool. However, if you plan to work on larger projects or work with more intricate materials, you may want to consider investing in a more powerful model.

It is important to remember that although low shank sewing machines are quite simple to operate, they can still lead to some issues. For instance, the smaller size can make it difficult to maneuver around and through larger materials, making it harder to sew consistently. Additionally, adjusting the tension settings of a low shank machine can be difficult, so it is important to consult a professional to make sure that the tension is correctly adjusted before starting a project.

Tips for Sewing on Low Shank Sewing Machines

If you plan to use a low shank sewing machine, it is important to make sure that it is in good repair and that the tension settings are correctly adjusted before starting a project. Additionally, it is important to choose a machine that offers adequate power to handle the types of fabrics you plan to use. Finally, make sure to practice using the machine before undertaking a large project to ensure that you are comfortable with it.

Using a low shank sewing machine requires a bit of practice and patience, but it can be a great way to learn the basics of sewing. As long as you take the time to ensure the machine is in good repair and the tension settings are adjusted correctly, you can create impressive projects with a low shank machine.

Accessorizing for Low Shank Machines

Adding the right accessories to your low shank sewing machine can make a big difference in the quality of your projects. Some of the most useful accessory items include special feet for different materials and projects as well as a seam ripper, a fabric cutter, and an extra power cord. Additionally, consider buying extra needles and bobbins to have on hand when needed.

Some low shank machines also offer the option of adding a table or extension table, which can be especially useful for larger projects. This can provide extra working space, making it easier to manipulate fabric and maneuver the machine. Finally, consider buying a high-quality carrying case to transport your sewing machine and keep it safe.

Maintenance and Care for Low Shank Machines

Regularly cleaning and lubricating your low shank sewing machine is key to ensuring that it runs smoothly and efficiently. The best way to clean a low shank machine is to use a soft brush to remove any lint or thread particles that might have gathered on or around the machine. Additionally, it is important to oil the parts of the machine on a regular basis as this can help to prevent rust.

When not in use, it is also important to keep your low shank machine covered to protect it from dust and debris. Additionally, it is important to make sure that the power cord is unplugged from the wall whenever the machine is not in use to prevent any electrical accidents. By following these steps, you can ensure that your low shank machine remains in good working order for years to come.

General Sewing Tips for Low Shank Machines

It is important to start off with the best possible fabric and thread for the project you are working on. Investing in high-quality materials can make a big difference in the outcome of your project. Additionally, it is important to ensure that the fabric is well pressed before sewing, as this can prevent unwanted wrinkles and make it easier to work with.

When threading your low shank machine, it is important to be precise and make sure that the thread is correctly inserted into the machine. Additionally, it is important to ensure that the tension settings are correctly adjusted and that the bobbin is correctly filled. Finally, it is important to check your work regularly to make sure that the stitches are even and the tension is correct.

Sewing with a low shank machine can be an enjoyable and rewarding experience. With the right fabric, thread and accessories, as well as the correct tension settings and practice, you can create beautiful, professional-looking projects in no time.