According to The Sewing Machine Technician’s Manual, bobbin size and type is not universal.

The same manual states that bobbins should never be changed from one sewing machine to the next, unless instructed by an authorized sewing machine technician. Sewing machine bobbins come in different sizes, shapes and materials, even though all are usually manufactured based on an industrial standard or design, similar to the standard home sewing machine.

Manufacturers produce their own proprietary sewing machine bobbins and some can be interchangeable with certain models from other manufacturers. However, it is extremely important to double-check compatibility first, as different types of bobbins may not fit all machines. Bobbins that do not fit properly can cause serious problems, including jams and malfunctions.

Whether they are metal, plastic or composite, all bobbins have the same basic components and configuration. Some of the more common types of bobbins that can be found today include older metal bobbins, plastic Class 15 bobbins and plastic Class 66 bobbins.

Older metal bobbins, which are also referred to as shuttle bobbins, are typically either one-half or one-third the diameter of the average plastic bobbin. Because they are made of metal, they have a longer life and are more durable than comparable plastic bobbins.

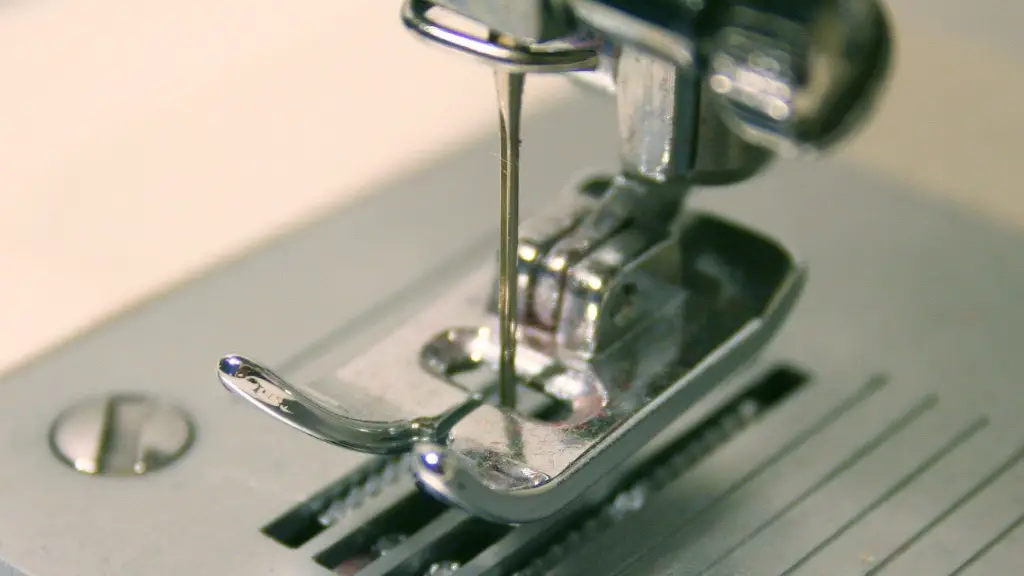

Class 15 plastic bobbins are slightly narrower than metal bobbins and are designed to fit 1/4-inch wide or less feed dogs. Class 66 plastic bobbins, on the other hand, are wider than Class 15 plastic bobbins and are designed to fit 15/16-inch wide or more feed dogs.

However, sewing machine bobbins are only one part of the equation when it comes to achieving the perfect stitch. It is important to choose bobbins that are strong, smooth and balanced in order to obtain the best results. Also, proper tension should be maintained and the bobbin should be regularly serviced in order to prevent sewing machine malfunctions.

Bobbin Material and Longevity

The materials used to make a bobbin are also important in determining the longevity of a bobbin. Metal bobbins are generally more durable and may even last longer than plastic ones. On the other hand, plastic bobbins may be easier to use and less prone to slipping or jamming than metal bobbins.

Regardless of their material, all bobbins should be regularly checked for signs of wear and tear. If a bobbin shows signs of wear or damage, it should be replaced immediately. This is especially true for plastic bobbins, as they tend to break or loosen easily.

Newer models of sewing machines may also require a different type of bobbin, so it is always best to check the user manual before buying a new bobbin. Additionally, only high-quality bobbins should be used as low-quality ones can cause tension problems, resulting in uneven stitches.

Storing Bobbins

Bobbins should be stored in their original containers and not just thrown into a cupboard or drawer. Over time, the sharp edges of the plastic containers can cause damage to the plastic bobbins, which will reduce their life expectancy.

The plastic containers also help to keep bobbins from moving around and causing potential problems. If plastic bobbins are placed next to metal ones, the sharp edges of the metal bobbins may cause scratches and indentations in the plastic bobbins.

It is also important to make sure that the bobbins are not exposed to direct sunlight or high temperatures. Exposure to these elements can cause the plastic bobbins to become brittle and warp, which can lead to tension problems.

Bobbin Winders

For those who need to replace old bobbins or wind up a lot of bobbins, having a bobbin winder is essential. Bobbin winders come in a range of sizes and models, depending on the type of machine the bobbins are being used for.

The bobbin winder essentially replaces the sewing machine’s tension discs and arms and is used for winding bobbins in an even and consistent manner. While most bobbin winders are designed for specific models of sewing machines, there are also universal models that can be used for most standard sewing machines.

When using a bobbin winder, it is important to ensure that the correct amount of tension is applied to the bobbin. Too little tension may cause the bobbin to be too loose, while too much tension could cause the bobbin to be wound too tightly.

Additionally, it is also important to keep an eye on the bobbin as it is being loaded, to ensure that it is loaded and wound properly. This way, the bobbin can be monitored for signs of wear and tear and any problems can be addressed before it causes any damage to the sewing machine.

Threading the Bobbin

Threading the bobbin correctly is also essential in achieving a perfect stitch. The bobbin should be threaded correctly according to the manufacturer’s instructions, which can be found in the user manual or on the machine itself.

The bobbin should be threaded through the bobbin case and not just placed in the case, as this could cause the bobbin to become loose or cause tension problems. It is also important to make sure that the thread is properly placed in the bobbin case so that it is not tangled or snag on any of the bobbin’s components.

Once the bobbin is correctly threaded, the bobbin case should be checked to make sure that the thread is properly aligned and tensioned. Too much tension could cause the thread to break, while too little tension could cause the bobbin to slip, resulting in uneven stitches.

Maintaining Bobbins

Finally, it is important to regularly maintain all bobbins, regardless of their type or brand. This means cleaning the bobbins and replacing any worn or damaged parts. Doing so will help to extend the life of the bobbin and ensure that it continues to work properly.

It is also important to keep an eye on the bobbin case, as it can become worn over time. If the bobbin case shows signs of wear, such as deep scratches or fatigue marks, it should be replaced as soon as possible.

Additionally, bobbins that have been used in wet and humid environments should be cleaned and lubricated regularly. This will help to prevent rust and ensure that the bobbin continues to perform optimally.

Conclusion

In conclusion, it is important to remember that sewing machine bobbins are not universal and should not be substituted from one machine to another without double-checking compatibility. Proper maintenance of bobbins is also essential in order to get the best possible results from a sewing machine.