An Exploration of Leather Sewing Machines

In today’s world of fashion, sewing machines are being used to craft amazing styles out of versatile materials, many of which include leather. Many people wonder if it is possible to sew leather with a sewing machine, and the answer is a resounding yes. There are a few tricks and techniques to be aware of when using a machine to sew leather, but with the right preparation and practice, sewing with leather can become a favourite pastime.

When utilizing a sewing machine for leather craft, selecting the right thread, needle and backing is crucial. The thread should be made of polyester for durability, as cotton is not strong enough to last through leather seams. The same goes for the needle; always opt for a heavy-duty needle with a strong point for piercing through thick leather. Depending on the backing of the leather piece, an appropriate stabilizer should be used to avoid puckering.

Another important element of sewing leather is choosing the correct stitch length, which allows the machine to sew through the material without becoming overloaded. Opting for a mid-range stitch length of around 2.5 usually works best; any longer, and the threads may easily become tangled and any shorter, the leather might not get securely stitched together.

Additionally, for extra strength, multiple layers of leather can be stitched and fastened together with rivets or other materials. Joining straps to leather wallets is an example of how to do this correctly, as it provides long-lasting and secure attachment points.

When finishing seams on leather, the raw edges can be treated differently depending on the project at hand. For a more natural finish, a folding technique can be used where the edge is folded inward and stitched down, resulting in a very neat seam. Alternatively, the edge can be encased in a binding tape which provides a smooth edge and prevents fraying.

Of course, understanding the right settings to use when sew leather is key, as issues such as fabric shredding or thread breakage can occur if they are incorrect. Therefore, it is helpful to consult with experts who specialize in manufacturing leather products and inquire about the ideal machine settings and suggest the best tools and materials for the job.

Given the right tools and quality materials, sewing machine users should be able to confidently work through light to medium weight leather with ease. Once the basics of leather sewing have been mastered, the possibilities to create beautiful products from leather are virtually limitless.

Expert Perspectives on Sewing Leather

When considering sewing leather, it’s important to understand the best methods for achieving perfect stitches and professional finish. Drawing on experts in the leather goods industry, below is a summary of the top tips for success when using a sewing machine.

A sewing machine technician suggests running an extra-long stitch length when handling heavier leathers such as suede, as it provides a secure stitching pattern. In addition, the suggestion is to use a heavier thread, such as nylon or polyester, and a larger needle compatible with the leather type, in order to counteract ruptures.

A leather goods designer shares that when attaching hardware to leather, he always starts with a tight zigzag stitch to secure the ends in place, followed by a running stitch for support up the sides. This ensures that the hardware does not come loose and provides a professional finish to the product.

Another leather expert suggest to use the regular uneven stitch when working with two pieces of fabric and seam them together. This stitch helps add strength and is great for more intricate pieces, forming an “X” pattern which reinforces the seams and prevents tearing.

Finally, an e-commerce seller of leather goods advises to practice on different pieces of leather with varying weights and thicknesses to develop an understanding of how the different settings work in combination with the tools being used. Above all, it is important to start with a basic stitch, such as a running stitch, as this will help you to adjust the tension and gain confidence sewing through the leather.

Beyond the Basics: Layer and Laminate Leather

When a leather project has been completed through basic stitching, there are plenty of ways to step up its function and design. For example, lamination can be used to create a unique texture or build a three-dimensional effect. Various kinds of leather and even bonded leather can be applied to the outer layer of the leather piece in order to create an interesting look.

To accomplish this, it is necessary to choose the right adhesive, along with its corresponding glue guns and spreaders, which involve heat and pressure to attach the pieces together. It is essential that the adhesive is compatible with the glue gun and the leather material, to ensure a strong hold and that the layers adhere properly.

Layering is another great way to enhance design elements. Two pieces of leather can be stitched together, such as with a saddle stitched pattern, to form a pocket to hold a wallet, phone or other device. With layering, it is possible to use different sizes and colours of leather to achieve a decorative, unique look.

For personalization or further embellishment, embossing or engraving can be done on the leather. By embossing the material instead of directly embroidering or painting onto it, the natural texture of the leather is preserved, resulting in an elegant look. Products such as stampers, embossers and even laser engravers can be used to achieve this.

Tools and Materials Used when Sewing Leather

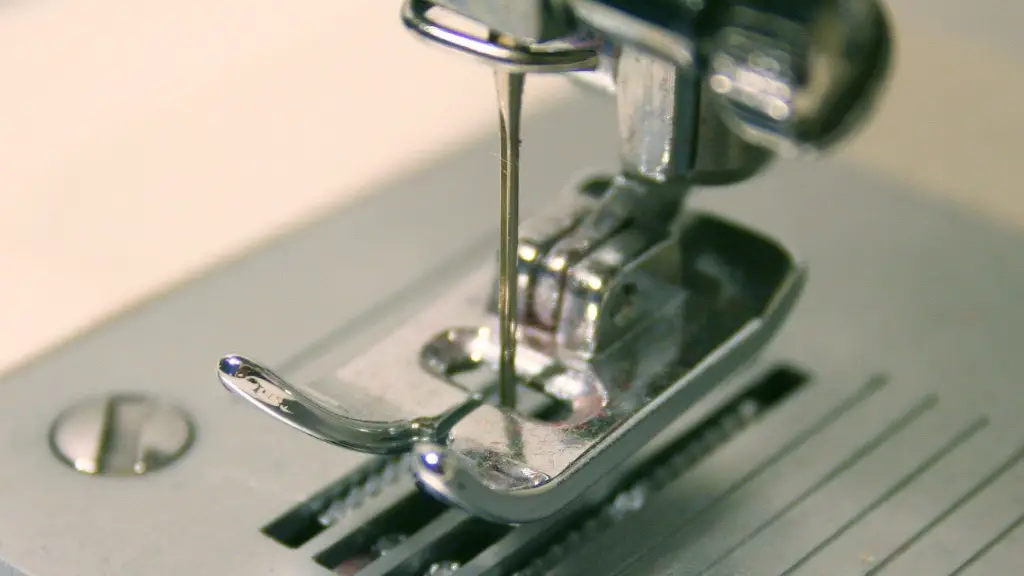

As with any type of sewing, it is important to have the right tools and materials in order to correctly and safely sew leather. The basics include heavy-duty needles and threads that are appropriate for the leather in hand, as well as a steady body presser foot that is appropriate for the weight of the leather in hand. Electric shears are helpful to easily trim away excess material, while standard scissors can be used to snip threads where needed.

It is also a good practice to use a Teflon presser foot, which is coated with a heat-resistant substance and has a non-stick surface, allowing for a smoother movement as the needle moves through the leather. This not only reduces wear on the needle, but also prevents the fabric from sticking to the bottom of the presser foot and causing puckering.

Aside from the basics, other leather tools can be utilized such as edge creasers, rivet setters and leather punches. Edge creasers, which come in different shapes, help to define folds and edges of leather pieces, while rivet setters are important for securely fastening metal plates and rings onto leather. For more intricate details, leather punches can be used and come with varying tip sizes to create precise cuts into the leather.

Caring for Your Leather Pieces

When sewing leather, it is important to keep in mind that leather is a natural material and it requires special attention when it comes to treatment and cleaning. To keep leather in good condition, it is important to take preventative measures such as regularly applying a moisturizer, weather-proofing agents or leather conditioners that are appropriate for the leather.

These agents are essentially thin oils or waxes that block out moisture and repel dust, but will not affect or change the color or texture of the leather when applied. This helps to keep the leather from cracking or fading under direct sunlight or heat, which could ruin the piece and disappear years of hard work.

In addition, it is wise to not overload the pieces, as excess weight may cause the leather to stretch or distort the shape. This could be avoided by opt for the right needles and threads for the piece, as well as utilizing topstitching or extra layers of leather for added reinforcement.

Tips to Achieve Professional Finish

In order to get a truly professional finish on leather pieces, here are a few tips to keep in mind. Firstly, utilize a professional-grade sewing machine needle to minimize any skipped stitches or broken threads. Also, use an appropriate presser foot for the leather; depending on the material, a roller foot or an acute-angle foot could be best.

Also, make sure to use a proper presser foot, as it will be less likely to slip and cause puckering. Finally, before beginning a project, test out various stitch types and lengths on scrap pieces of leather before starting your main project.

Conclusion

Leather sewing is a great way to explore creativity and build beautiful products while adding a touch of personalization. With the right tools and techniques, even the most intricate of leather designs can be achieved by using a sewing machine. Through selecting the correct needle, thread and appropriate settings, as well as laminating, layering and various treatments, it is possible to create exquisite and durable leather pieces with amazing precision.