Threading the needle

Threading a sewing machine can seem like an intimidating process, but it’s actually a fairly simple task once you learn the basics. All machine models are different, but they all involve threading the needle, guiding the thread around the tension, and finally spooling the thread into the bobbin. With a bit of practice, anyone can easily master threading a sewing machine.

Parts of the Sewing Machine

The first step in threading a sewing machine is to familiarize yourself with the parts and their functions. Most sewing machine models feature a needle, needle threader, spool pin, bobbin winder, bobbin case, tension, take-up lever, and presser foot. The spool holds the thread that is made up of all the small fibers. This thread is wound around the bobbin and then put into the bobbin case which drives the needle thread.

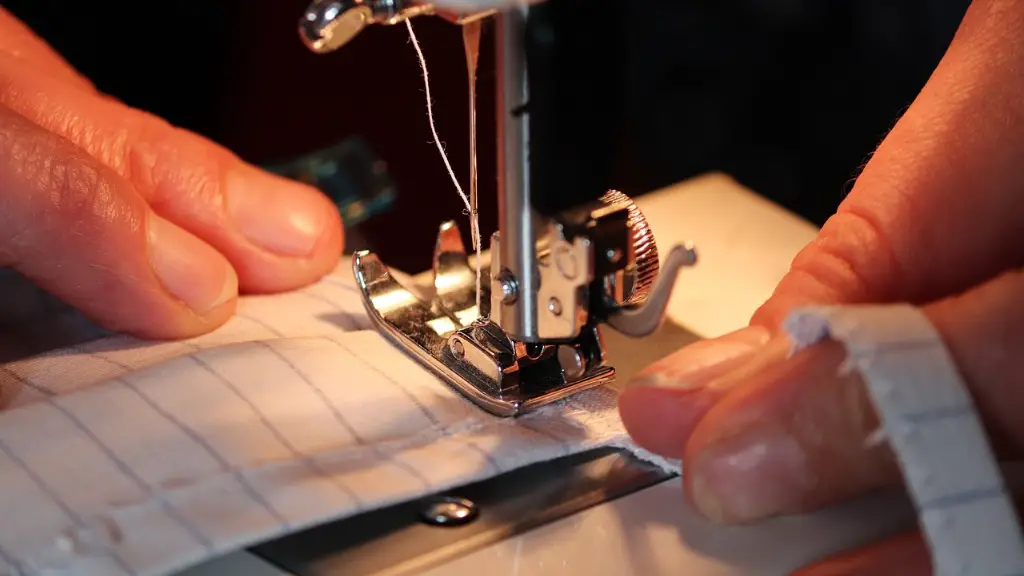

Thread the Needle

Once you have identified the parts and their functions, the next step is to thread the needle. Start by winding the thread around the spool pin to anchor the thread in place. Most sewing machine models will include a needle threader to make this process easier, but if not, many experts suggest using a dental floss threader. To do this, place the loop of the dental floss threader across the eye of the needle, push the threader and the loop onto the shaft of the needle, and pull the threader back through the eye of the needle.

Guide the Thread Around the Tension

After threading the needle, it’s important to guide the thread around the tension. Tension is what will give the fabric you’re working with the proper material grip. Many experts suggest a topstitch needle with larger eyes and a thicker shaft to help control the tension. If the thread isn’t properly tensioned, it may cause skipped stitches or too-loose hems.

Bobbin Thread

The final step is to spool the thread into the bobbin. To do this, insert the spool of thread onto the spool pin and then wind it around the bobbin. The bobbin should be wound with the same tension as the spool of thread. When the bobbin is full, the machine can be loaded in its designated place. After the bobbin has been secured in its place, the top thread can be pulled down and the machine is ready for use.

Wrapping up

Threading a sewing machine is an essential skill for anyone interested in sewing or crafting. Although it may seem like a daunting task, it’s actually quite simple. By following the steps outlined above, you’ll be threading a machine in no time.

Getting Started

When attempting to thread a sewing machine for the first time, it’s important to read the user guide. This will provide step-by-step instructions on how to correctly thread the machine, which can be extremely helpful. Many models will also include diagrams that can be used as a reference.

If the machine has an automatic needle threader, it’s still important to understand how to manually thread the needle and guide the thread around the tension. It may take some time to master all the steps, but with a bit of practice, anyone can easily learn how to thread a sewing machine.

Troubleshooting

If you run into any problems while threading the machine, the first step is to refer to the user guide or the diagrams included with the machine. However, if the problem persists, it’s best to contact the manufacturer for assistance. They can help you troubleshoot the problem so that you can get back to sewing in no time.

Alternatives Solutions

In addition to manual threading, many modern sewing machines also come with an automatic threader that eliminates the need to thread the needle manually. The user simply needs to follow the instructions in the user guide and the machine will do the rest. Although more expensive than manual machines, these automated models can make the threading process much faster and easier.

Aesthetics

Some users may also prefer the aesthetic qualities of certain machines. Before purchasing a machine, it’s important to consider the overall look and feel of the machine. Although this won’t directly affect the threading process, it can make a big difference when selecting the perfect machine for you.

Shopping for a Machine

When shopping for a new machine, many people consider a variety of factors such as cost, features, and ease of use. It’s important to choose a machine that meets your needs and the requirements of the projects you plan to take on. One of the best ways to determine the right machine for you is to read online reviews and ask experienced sewists for their opinions.

Maintenance

In addition to threading, it’s also important to keep up with regular maintenance of the sewing machine. This includes oiling, replacing worn parts, and gently cleaning the machine. Regular maintenance will ensure that your machine continues to produce stitch-perfect results and lasts for many years to come.