How to Adjust Sewing Machine Bobbin Tension

Adjusting the bobbin tension of your sewing machine is essential to successful sewing. The bobbin provides the thread that gives the fabric depth and character. If the tension is too loose, the bobbin thread will be visible on the right side of the fabric. If the tension is too tight, the fabric may pucker or the seam may be too tight. Getting the bobbin tension just right is the key to creating beautiful and consistent stitches.

Check the Bobbin

The first step in adjusting bobbin tension is to check the bobbin to make sure it is the correct type for your machine. Different models and brands require different types of bobbins, so it is important to check to ensure a perfect fit. Once you have the right bobbin, you can move on to the next step.

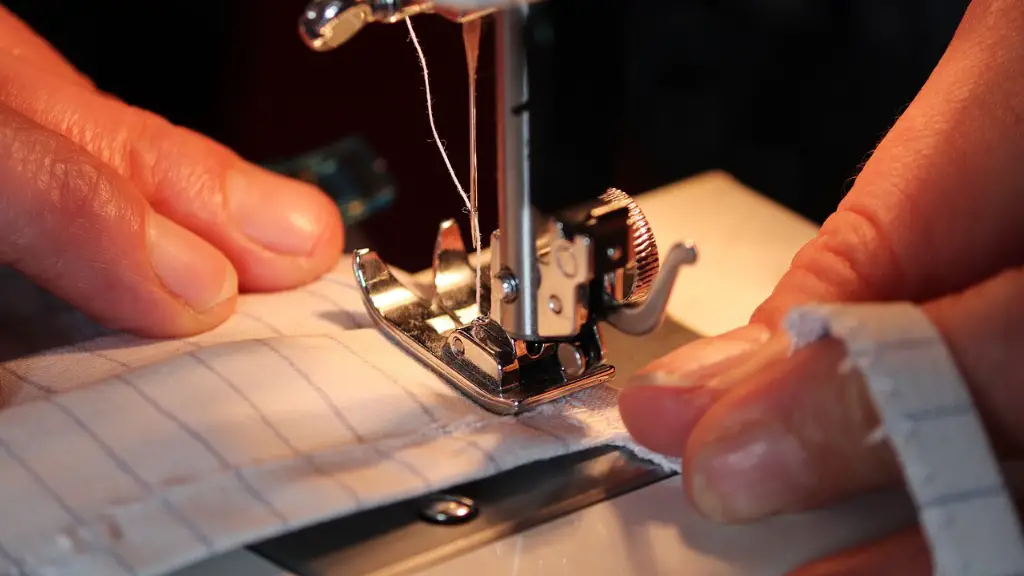

Test the Stitch

Next, it’s time to actually test the stitch. Set up a straight line of stitching and run a few stitches. Take a look at the fabric and stitches carefully. If the bobbin thread is visible on the other side, the tension needs to be adjusted. If the stitch is puckered, it is likely that the tension is too tight.

Tighten or Loosen the Bobbin Tension

Now that you know if the tension needs to be tightened or loosened, it’s time to adjust it. Locate the tension spring on the side of the bobbin case, and use a screwdriver to adjust it. If the tension needs to be loosened, turn the tension spring counterclockwise, and if it needs to be tightened, turn it clockwise. Make sure to check the stitch after each adjustment.

Replace the Bobbin Case

Once you have achieved the desired tension, replace the bobbin case. Ensure that it is properly aligned and secure in its place. Make sure to test the bobbin once more to ensure that the tension is correct.

Cleaning and Inspection

Regular cleaning and inspection of the bobbin and bobbin case should also be done. It is important to check the bobbin case for debris that may be stuck in cracks or crevices. This debris can interfere with the tension, so removing it can help keep your sewing machine in top form.

Professional Adjustment

If you are unable to adjust the bobbin tension yourself, it is best to take it to a professional. They will be able to diagnose any problems with the machine and adjust the tension as needed.

Choosing High Quality Bobbins

The quality of the bobbin is important to get the perfect tension. Make sure to use high-quality bobbins to ensure consistent and perfect stitches. Lower quality bobbins can cause tension issues and may need to be replaced more often.

Tips for Troubleshooting Problems

If you are having trouble getting the tension just right, there are a few tips to consider. Make sure that the bobbin is not overfilled or underfilled. This can cause the tension to be off balance. Additionally, be mindful not to overload the machine as this can also lead to tension issues.

Important Safety Precautions

When adjusting the bobbin tension, it is important to remember to turn off and unplug the machine. This is for safety reasons, so that you do not get injured by the machine running unexpectedly.

Replacing Worn Out Parts

Over time, parts of the machine can become worn out from use. This can lead to tension issues, so make sure to check for worn-out parts and replace them as needed. This will help to ensure consistent and perfect stitches.

Tension Adjustment Tools

For those who are more experienced with sewing machines, special tools can be used to help with tension adjustment. Different tension adjustment tools can be used to make the process faster and easier. These tools are usually inexpensive, so they are well worth the investment.

Methods to Change Tension

There are two main methods used to adjust the bobbin tension. The first method is to adjust the tension screw on the bobbin case itself. The second method is to adjust the tension of the thread itself. Each method will work differently depending on the fabric, so you may need to experiment with each.

The Role of the Bobbin Thread

It is important to remember that the bobbin thread plays an important role in providing texture and character to the fabric. Adjusting the bobbin tension can make a huge difference in the finished product. It is thus important to take the time to get the tension just right and to practice with various fabrics.

Understanding the Different Fabrics

The tension needs may differ depending on the type of fabric used in the project. Lightweight fabrics will require lighter tension, while thicker fabrics may need a tighter tension. Take the time to experiment with your machine and fabrics until you find the right balance.

Tension Settings and Threads

It is also important to consider the type of thread and the thread weight when adjusting the bobbin tension. The lighter the thread, the lighter the tension should be. Thicker threads will require a slightly tighter tension.

Tips for Maintaining Good Tension

Finally, it is important to maintain good tension for successful sewing. This can be done by regular cleaning and inspection of the bobbin and bobbin case. As well, make sure to use the correct bobbin size and choose high quality bobbins. Additionally, check the thread tension regularly and replace worn-out parts. Following these steps will help keep your bobbin tension just right.