Background Information

Sewing machines are a necessary tool for any sewers out there who like to stitch up clothing, fabric and other items. Not only do they make it easier to sew quickly and neatly, but they’re also great investment pieces that can last decades or even centuries with proper maintenance. But like any other machine, sewing machines can become worn over time and require repairs. Fortunately, fixing an old sewing machine doesn’t have to be a daunting task. There are a few steps you can take to repair your machine and get it running like new.

Inspect the Machine and Gather Supplies

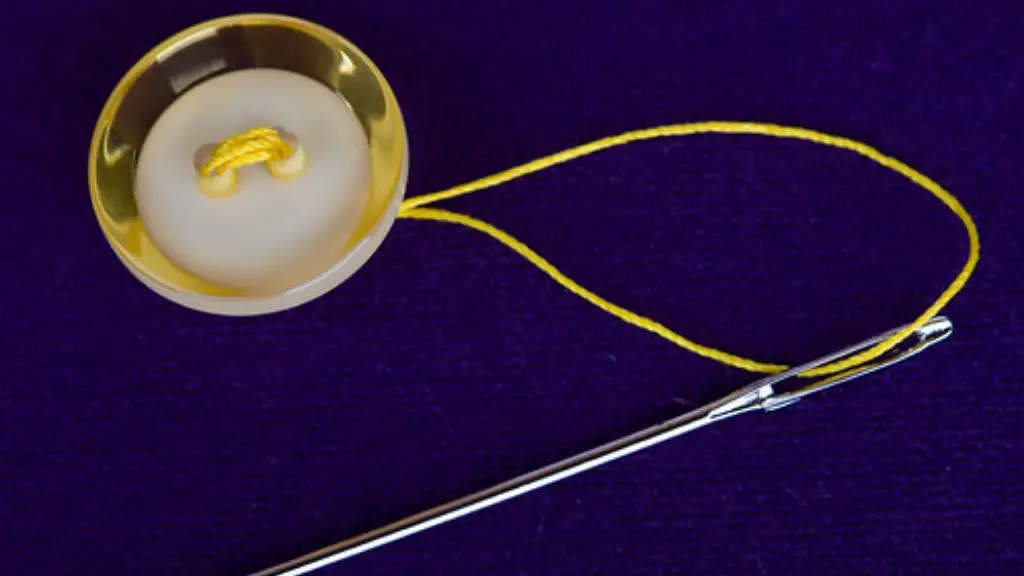

The first step in repairing an old sewing machine is to inspect the machine and see what needs to be fixed. You’ll also want to gather up the supplies and tools you’ll need to make the repair. Common items you may need include a screwdriver, oil, needle, and thread. Once you have everything ready, it’s time to start the repairs.

Lubricate and Adjust the Machine

One of the most common problems with old sewing machines is that the gears and parts become dry and worn out, which can cause the machine to jam and make it difficult to sew. To keep the machine running smoothly, it’s important to lubricate the gears and parts. This can be done with a simple lubricant like sewing machine oil. You may also need to adjust the tension of the machine, which can be done with a simple screwdriver.

Replace Worn or Broken Parts

If the machine is still having problems after lubricating and adjusting it, you may need to replace worn or broken parts. Look for any pieces that are cracked or missing, and replace them with new parts. Finding the right parts can be difficult, so it’s important to take accurate measurements or look up the machine model to ensure you get the right parts.

Clean the Machine

Another important step in fixing an old sewing machine is to clean it thoroughly. Remove any dust and debris from the machine and clean the bobbin, needle and other components. This will help ensure that the machine is running smoothly and will help prevent future problems.

Test the Machine

Once you’ve inspected, lubricated, adjusted, and cleaned the sewing machine, it’s time to test it out. Put some fabric in the machine and test it out on a scrap piece of fabric. This will help you assess whether or not the repairs were successful and if there are any further adjustments that need to be made.

Safety Checks

The last step in repairing an old sewing machine is to make sure the machine is completely safe to use. Check the cord and plug for signs of wear and tear, and make sure the power switch is working properly. Additionally, inspect the needle and bobbin for signs of wear. These steps will help ensure that the machine is safe and functioning properly.

Advanced Maintenance

In addition to the regular maintenance you’ll need to do on an old sewing machine, there are a few advanced steps you can take to further extend its life and performance.

Inspect for Damaged Wires

One of the more advanced maintenance steps you can do on an old sewing machine is to inspect the wires for damage. Look around the plug, power switch, and other areas of the machine to check for any worn out or frayed wires. If you find any damaged wires, replace them with new ones to ensure the machine is working correctly.

Replace Any Missing Screws

Another step to take is to replace any missing screws. This will help keep the machine running smoothly and help prevent any further damage. Take a look around the machine and check for missing screws, then replace them with new ones.

Adjust the Tension

In some cases, you may need to adjust the tension on the machine. This can be done with a simple screwdriver, however, it’s important to be careful and follow the instructions carefully. Too much or too little tension can cause problems with the machine and make it difficult to sew properly.

Check for Wear and Tear

Finally, inspect the machine for signs of wear and tear. Look at the gears and other parts for indications of wear. If you spot any worn out parts, replace them with new ones. A worn out machine is more prone to jamming and having problems, so replacing worn out parts can help ensure that your machine is running smoothly.