How to Fix Loose Thread in Sewing Machine

Sewing machines are one of the most valuable and useful tools in any sewing room. Without them, it would be virtually impossible to produce a finished piece in any sort of timely manner. Unfortunately, because of their reliance on physical components, they can suffer from loose thread, dropping or improperly stitching the fabric. Loose thread can be a common occurrence in high-end sewing machines and is something that must be corrected if the quality of the finished product is to be maintained. The following information can help to explain what causes loose thread in a sewing machine and how to fix it.

In most cases, loose thread occurs due to a lack of tension between the upper and lower thread loops. The tension is achieved by making sure that both of the thread loops are tightly wrapped around their respective spindles, then attaching the spool of thread to the machine and adjusting the tension controllers. If this tension is not properly maintained, the loops will be too loose and therefore, will not keep the thread from slipping either during or between stitches.

The first and simplest way to fix loose thread in the sewing machine is to adjust the tension. This can be done by adjusting the tension controllers and making sure that the thread loops are tightly wrapped. It is also important to check the thread itself and make sure it is not worn, frayed, or damaged in any way. If it is, it should be replaced with a new spool of thread.

Another possible cause of loose thread in the sewing machine is incorrect needle placement. The needle should be placed directly underneath the fabric being stitched and at the same height and distance from the spool of thread. If the needle is too close to the thread, it will snag, resulting in excessive and uneven tension. To fix this issue, the needle should be moved slightly away from the thread.

It is also important to ensure that the bobbin case has been properly threaded. The bobbin case is the part of the machine responsible for controlling the tension on the bottom thread loop. In order for it to work properly, it must be threaded correctly and the upper and lower thread should be aligned. If the bobbin case is not threaded correctly, the tension will be uneven, resulting in sloppy stitches and loose thread.

Dusting and Cleaning Machine

One of the best ways to prevent loose thread in a sewing machine is to make sure it is kept clean and free of dust. Dust and dirt can collect in the nooks and crannies of the machine, causing the machine to vibrate differently and resulting in uneven stitches and loose thread. To clean the machine, use an anti-static dusting cloth and wipe down the outside of the machine as well as the bobbin case and threading hook.

If the dust cannot be removed with a soft cloth, then a compressed air canister can be used to blow out the dirt and dust from all the small crevices. This will help to ensure that the machine is operating smoothly and without disruption. Additionally, it is important to periodically inspect the machine’s internal components and make sure all of them are operating correctly.

The hook timing should also be checked to ensure that it is set properly. This is the part of the machine which determines the speed of the hook and the needle. If it is not set correctly, then the thread will not be looped properly and this will result in loose thread. However, hook timing can be adjusted without the need for specialized tools or equipment by simply following the instructions provided in the sewing machine’s manual.

Lubricating Parts

Lastly, it is important to properly lubricate the parts inside the machine. Sewing machines use a variety of lubricants such as oil and grease to help keep their parts working and moving properly. If these lubricants are not regularly applied, then the parts may become dry and this will result in increased friction which can affect the tension in the loops and result in loose thread.

The best way to properly lubricate the parts of the sewing machine is to use a high-quality lubricant specifically designed for use in sewing machines. These lubricants can be found in most craft stores and can be applied using the instructions provided in the sewing machine’s manual. It is also important to remember to regularly clean the parts of the sewing machine after they have been lubricated.

These are the most common causes of loose thread in a sewing machine and how to fix them. By properly maintaining the machine, keeping it clean, inspecting it regularly, and adjusting the tension, one should be able to quickly and easily fix the problem of loose thread and keep their sewing projects looking professional and high-quality.

Adding Thread Weights

Adding thread weights can help to compensate for any loose thread that may arise from uneven tension. Thread weights are small metal plate-like objects that attach to the lower loop of the thread and provide additional tension for the stitches. They can be found in most craft stores and can be added to the machine in just a few simple steps.

Thread weights come in several different sizes and weights and by selecting one that is the correct size for your sewing machine, you can easily achieve the extra tension needed to prevent loose thread. Once the thread weight is added, make sure to re-check the tension and make any necessary adjustments to make sure the stitch is tight and secure.

Thread weights can also be used to secure fabrics that are challenging to sew, such as velvet, as they will provide an extra grip to keep the fabric in place. Furthermore, thread weights can also be used to reduce puckering of the fabric due to irregular tension.

Using the Right Needles

Another important factor to consider when correcting loose thread is to use the correct needle for the fabric being sewn. Different fabrics require different needles and the wrong needle can easily result in the thread becoming loose and slipping. For example, a thin and delicate material such as chiffon will require a thin and delicate needle, whereas a heavy denim material would require a thicker and longer needle.

The type of needle used can also affect the size of the seam allowance. Seam allowances refer to the gap between the stitches, and if the needle is too large or too small, this gap may become too large or too small and this can result in loose thread. It is best to refer to the manual which came with the machine to determine the correct needle size for the fabric being sewn.

Checking for Knots in the Thread

When dealing with loose thread, it is also important to check for knots in the thread. Knots can easily cause the thread to become loose and this can lead to uneven and messy stitches. To check for knots in the thread, simply run your finger along the length of the thread from the spool to the needle.

If the thread has knots, it will feel lumpy and uneven along the length of the thread. Small knots can be snipped off, but larger knots may require replacing the thread spool. Furthermore, using high-quality thread can help to reduce the likelihood of knots forming in the thread.

Replacing the Presser Foot

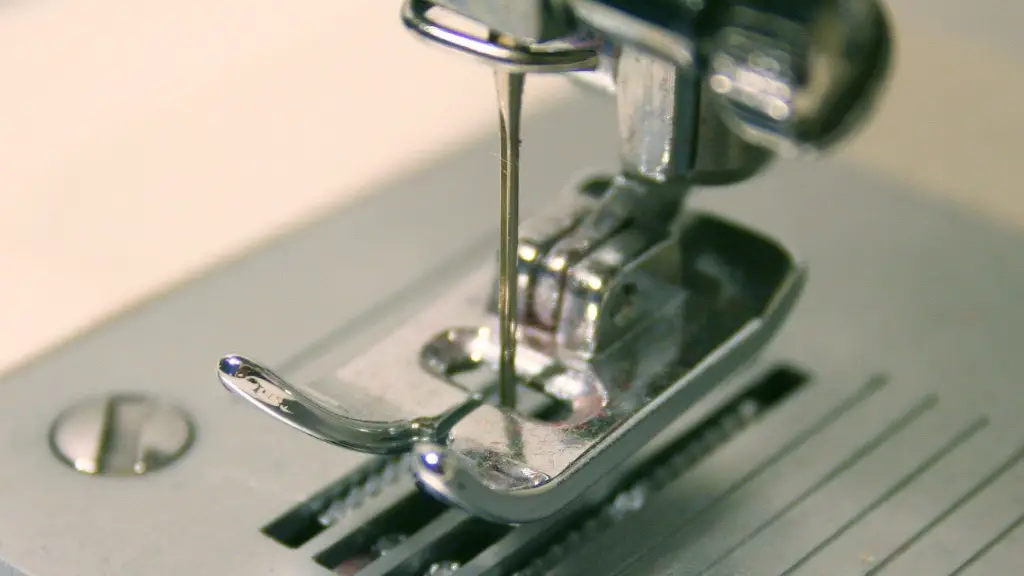

Finally, it is also important to inspect the presser foot. The presser foot is the part of the machine that holds the fabric in place and if the presser foot is not correctly mounted, the fabric can become loose and this can result in dropped stitches and loose thread. If the presser foot is damaged, it should be replaced with a new one.

In conclusion, loose thread in a sewing machine can be a common occurrence, but it can easily be corrected with just a few simple steps. By adjusting the tension, inspecting the machine, cleaning it, and properly lubricating the parts, one should be able to quickly and easily fix the problem of loose thread and keep their sewing projects looking professional and high-quality.