How to Fix the Tension in a Sewing Machine

Having tension issues when sewing is frustrating. It can cause skipped stitches, unraveling seams, and other undesirable results. But before you call it quits, you need to understand the root of the problem and how to fix it. The process of adjusting tension in a sewing machine is relatively simple, however it requires knowledge and practice. With this guide, you’ll be able to get to the bottom of the tension issue and make sure your work looks great!

Changing the Thread

The first thing to look at when fixing the tension on a machine is the type of thread. If the tension still isn’t right after making incremental changes to the tension knob, you should try a different thread. Threads come in different sizes, weights and fiber content. Make sure you are using a thread that is well-suited for the material you are sewing. When it comes to thread, it is better to go with a higher quality spool of thread as it can make a noticeable difference in the tension you experience.

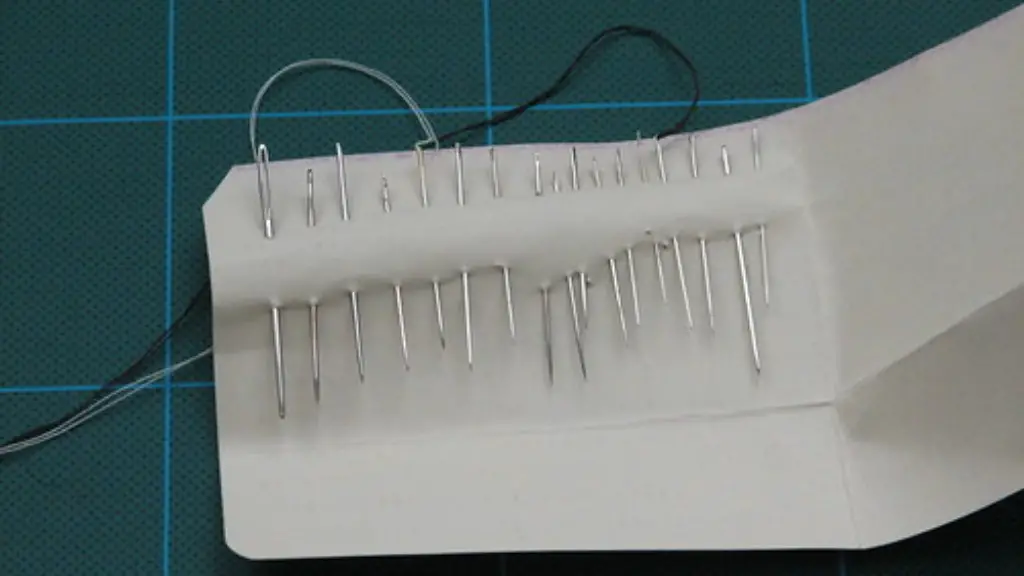

Use the Right Needle

Often times the problem with tension on a sewing machine can be attributed to using the wrong needle. Investing in good quality needles that are appropriate for the material you are working with is critical. Needles come in two sizes, 135×17 and 15×1. It is important to note which needle size you need to use so that it can work in tandem with the thread and not cause tension issues. Industrial machines need to use a heavier-duty needle than the home machines.

Adjust the Tension Knob

The tension of the thread is regulated by the tension knob on the sewing machine. Oftentimes this knob needs to be adjusted to get the tension of the thread to cooperate with the needle and fabric. To do so, turn the knob either to the left or the right in small increments until the tension of the threads is at the desired level. Be sure not to turn the tension knob too far in either direction or else the thread will be over-tensioned. It’s important to be mindful of the fact that different fabrics require different levels of tension, so it’s necessary to experiment with the tension knob to find the sweet spot.

Clean the Bobbin Case

If the tension knob doesn’t seem to be doing any good and the problem still persists, it might be time to look at the bobbin case. Bobbin cases often get covered with lint and dust which can interfere with the tension of the thread. To fix this problem, you’ll need to open up the bobbin case and clean it out with a small brush or toothpick. Be sure to be gentle and not scratch the bobbin case. After cleaning the bobbin case, it’s a good idea to put a drop of sewing machine oil on the bobbin case so that it moves smoothly while the machine is running.

Check the Bobbin

The bobbin is another place to check when you’re having trouble with your sewing machine tension. The bobbin must be wound evenly and fit into the bobbin case snugly. If the bobbin isn’t wound evenly, it can cause the tension of the thread to be off. A loose bobbin can also cause tension issues, so make sure the bobbin is properly inserted into the bobbin case.

Check the Upper Thread

If the bobbin and bobbin case seem to be okay, you should take a look at the upper thread. Make sure that the upper thread is passing through the tension disks evenly, and that the thread tail is not caught in the disk or caught in the fabric. If the thread is tangled or snagged, it can cause tension issues. A quick way to check this is to run the machine without the presser foot down and make sure the thread is passing through the tension disks as it should.

Check the Needle Plate

The next step to take is to check the needle plate. It’s possible that there is gunk or lint stuck between the needle plate and the needle. If so, it can interfere with the proper tension of the thread. To remedy this, use a cloth to carefully wipe it away. You can also drop a few drops of sewing machine oil onto the needle plate if it is squeaky or makes a grinding noise when the machine is running.

Tension Spring

The tension spring is the last thing you should check when having tension issues. This spring keeps the tension disks in place so that the needle and thread are properly tensioned. If this spring needs to be adjusted, it will be necessary to open the side of the machine and move the spring either to the left or the right. Remember to go slow and be mindful of the other components around the spring so that nothing else is broken or damaged.

Practice Makes Perfect

Adjusting the tension of a sewing machine can take a bit of practice. Have patience and start with small incremental changes so that you don’t overdo it. Once you have found the sweet spot for the tension and the right combination of thread, needle and machine setup, you will be on your way. Failures are to be expected when learning how to adjust the tension, so don’t get discouraged and take the time to learn what works best for your machine.

Tips For Improving Sewing Machine Performance

Beyond making sure the tension is accurately set on the machine, there are a few other tips you should follow to ensure your sewing projects turn out perfectly. Start by prepping the material before sewing. This means ironing it, tearing out any loose threads, and mending any tears. Not prepping the fabric properly can lead to big issues down the line, so be sure to do it before starting work. Additionally, always use a wide variety of needles for different materials throughout a project. As needles dull, the tension of the thread will suffer, leading to an unsatisfactory end result.

Sewing Machine Maintenance

Last but not least, maintenance is key. Make sure to oil the sewing machine often and keep it clean. This means wiping it down with a cloth after each use, and regularly cleaning out the lint and dust that builds up in the bobbin case and around the machine’s moving parts. This will ensure that your machine is running smoothly and that your sewing projects come out looking their best.

Advanced Sewing Techniques to Consider

Once you understand the basics of using a sewing machine, it’s a good idea to look into more advanced techniques. One technique that can come in handy is the use of a French seam. French seams are constructed by finishing the seam allowance inside the garment rather than outside, reducing bulk and giving a neat, beautiful look to your garments. Learning this technique is relatively easy – all you need to do is adjust the stitch length and presser foot pressure accordingly.

The Benefits of a Walking Foot

Another useful tool for a sewing machine owner is a walking foot. A walking foot attaches to the presser foot and ensures that the fabric is fed through the machine evenly and smoothly. This is especially useful when working with thick or slippery fabrics that can be difficult to sew with. It also reduces skipped stitches and tension issues, resulting in a beautifully finished project.

Finishing Touches for Perfectly Sewn Projects

Finally, a few finishing touches can go a long way towards creating a perfect sewing project. Edge trimming, for example, is something that can be done with a pair of pinking shears. This will help to prevent fraying of the fabric and give the finished look a nice, crisp edge. Another finishing touch is adding a hem – this can be done by folding the fabric over once or twice and stitching it in place with a decorative stitch or a nice serger roll.

Taking Sewing to the Next Level

By applying these tips and tricks, you can take your sewing skill to the next level. Don’t feel overwhelmed if your tension isn’t perfectly set right at first. With a little knowledge and some practice, you’ll be able to accomplish beautiful, professional-looking projects. Additionally, if you ever feel stuck or overwhelmed, remember to take a step back and consult your sewing machine’s manual for reference. It is sure to contain all the answers you need!