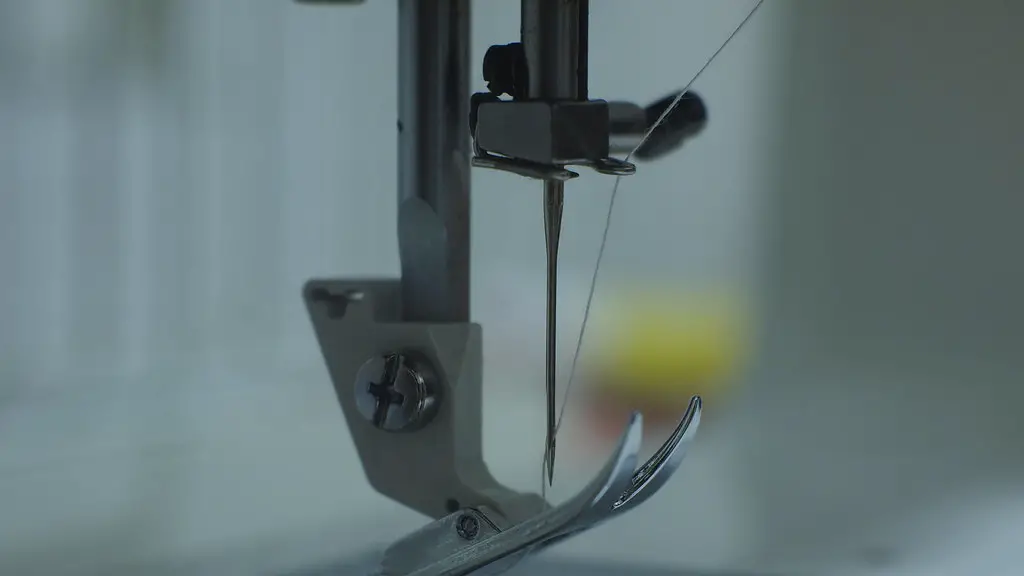

Do you have a sewing machine with tension threads you can’t seem to fix? If so, you’re not alone. Many sewing machine owners come across this issue, but thankfully it can be resolved with a few simple steps.

The first thing to do is inspect the threading on the machine. Check that the top and bottom threads are the same thickness and that they are the same type of thread. If one of the threads is thinner or of a different type, then this may be causing the tension issue.

The second step is to look at the tension settings on the machine. Make sure the tension disks on the machine are correctly adjusted. If the setting is too low or too high, then this could be causing the problem with the thread tension.

Some sewing machines may need to be cleaned and lubricated regularly to prevent thread tension issues. Check with your machine’s manual to find out how often you should clean and lubricate your machine. Also, check for any lint or debris in the tension disk area that could be inhibiting the thread tension.

If none of the above steps resolve the issue, then it’s time to call an expert. A qualified repair technician can take a look at the machine and make necessary adjustments to the thread tension.

In addition, using the right needles and threads makes all the difference in thread tension on sewing machines. Check to make sure the needles and threads you use on your machine are the correct type. This will ensure that thread tensions are not affected by improper thread or needle size.

Troubleshooting

If you still have difficulties with thread tension, then it’s time to troubleshoot. First, check to make sure the presser foot is on properly. The presser foot lifts the fabric and helps to guide it properly through the machine. Make sure there are no obstructions blocking the path of fabric as this can cause tension issues.

The bobbin case needs to be adjusted properly as well. This should be done by a qualified repair technician, but if you are experienced you can do it yourself. The bobbin case should fit snugly into the machine and the tension should be adjusted properly.

Lastly, always use manufacturer recommended threads, needles and accessories. Using the wrong type of thread can cause tension issues, as well as damage the machine. Using the wrong type of needle can also cause tension issues, and can be dangerous.

Additional Tips

In addition to the above-mentioned tips, there are some additional tips that can help you fix thread tension on your machine. First, avoid twisting your threads and make sure you thread the spools correctly.

Second, make sure the thread is not knotted or tangled. If the threads are caught or tangled, the tension will not be evenly distributed. This will cause the machine to run slower and the stitches to be uneven.

Third, if possible, use a thread stand. Thread stands can help reduce tension in the threads and make the sewing process go more smoothly. See if your sewing machine comes with a compatible thread stand.

Fourth, slow down the speed of your machine if necessary. Sewing machines don’t all sew at the same speed, so it’s important to adjust the speed as needed to ensure you’re sewing properly and not creating uneven or bubbled stitches.

Regular Maintenance

Regular maintenance is key to ensuring your machine runs optimally. Read and follow the recommended maintenance instructions for your machine. Make sure to do routine oiling, lubrication, cleaning and any other repairs or replacements that may be necessary.

When doing any maintenance, it’s also important to check the tension settings. If the settings are incorrect, then it can cause thread tension issues. Also, make sure all the parts are in working order and that they are in good condition.

You should also inspect the machine for any defects. Check the tension disks, lever, threading line and other parts of the machine to make sure they are in good working order.

Finally, don’t forget to test your machine once you’re done with any maintenance. Test it out with a few practice stitches to be sure that everything is in order and that the tension is working properly.

Helpful Accessories

Some helpful accessories can help with thread tension problems. A thread guide is a handy tool for threading the machine accurately. It just helps to keep the thread from becoming tangled or knotted, which could lead to tension issues.

Tension disks are another helpful accessory that can help keep the tension of the thread even. These disks will help you adjust the tension of the thread quickly and easily.

Finally, a thread gauge is an essential tool for ensuring that the thread is correctly tensioned. This tool will measure the thread tension, so you know if the tension is too low or too high.

Final Thoughts

Thread tension issues on sewing machines can be annoying and time-consuming, but they don’t have to be overwhelming. Following the above steps should help you resolve the issue quickly and get back to your projects.

Remember to inspect and adjust the thread tension, use the right threads and needles and do regular maintenance on your machine. These steps, combined with any helpful accessories, should help you fix thread tension issues with ease.