Setting Up the Janome Sewing Machine

Using a Janome sewing machine to insert needle is both fun and easy. Whether you’re a beginner or experienced sewer, it’s important to understand the basic steps for inserting the needle. Inserting the needle properly ensures you’ll get the desired results from your project. In this article, we’ll walk through the process of inserting the needle into your Janome sewing machine.

When starting to thread your machine, you’ll need a few supplies. It’s best to have the proper needle for the project, which you can find at your local fabric or craft store. You’ll also need scissors, a small screwdriver, a lint brush, a seam ripper, and a pair of tweezers. Make sure to have these supplies handy before you begin.

First, use the small screwdriver to remove the face plate of the machine. This will expose the needle bar and clamp, two components that work together to grip the needle. Align the needle bar so it’s pointing straight up and insert the new needle into the clamp, ensured the flat side of the needle is facing the back. Secure the needle by tightening the small screw on top until it holds the needle firmly in place.

Once the needle is in place, use the tweezers to make sure the needle is facing up, the right way. You may also need to make sure the needle has the correct size eye. In general, the Janome needle should be 2.5mm to 3.5mm, depending on the fabric you’re using. If the eye is too big, the fabric may not be tight enough when sewing.

Next, place the long thread onto the spool pin, followed by short thread onto the bobbin pin. To attach the thread to the bobbin, thread the short thread onto the bobbin pin, loop it around the spring lever, and slip it through the groove of the bobbin.

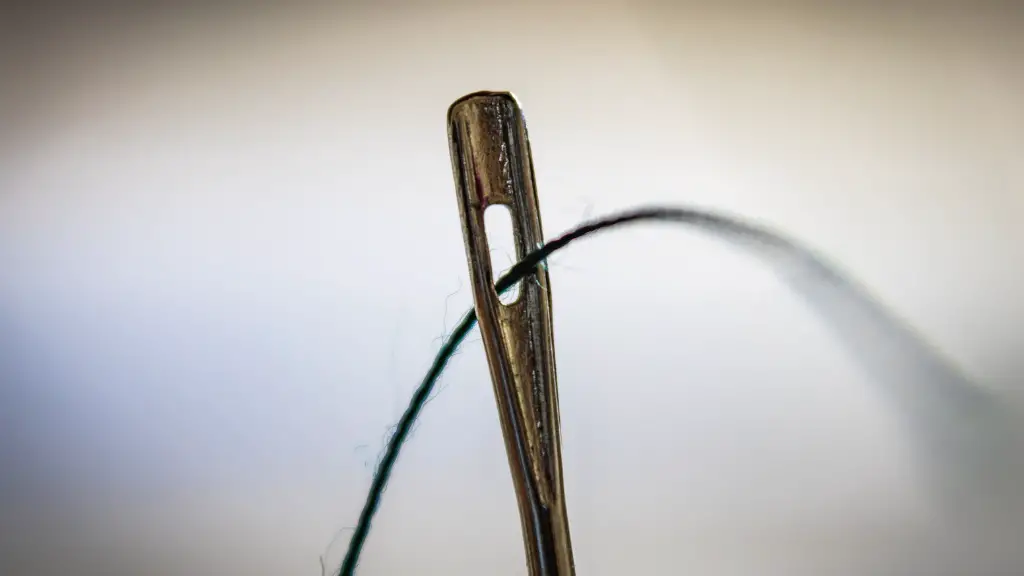

The last step is to thread the upper thread from the spool pin, guiding it through the eye of the needle. Then thread the bobbin case on the other end, which will complete the needle threading. Finally, take a few practice stitches on a piece of scrap fabric to make sure the thread is running through the machine correctly.

Cleaning Janome Sewing Machine

Regularly cleaning and oiling your machine will help extend its life and improve performance. Cleaning and oiling should be done after every sewing project, or every few months. Start by first turning off the power and unplugging the machine, then use a lint brush to remove any lint or debris.

Using a soft cloth, clean any dirt and dust that has gathered on the exterior and around the needle. Be sure to move the needle up and down a few times and rotate the manual wheel as you go. This will help loosen up any dirt or debris that may have become lodged in the mechanism.

Next, you will need to oil the machine to keep it running smoothly. Oil the hook and shuttle of the machine, applying 1-2 drops of oil in each area. Refer to the owner’s manual for the specific type of oil to use. Finally, check the pressure setting on the dial and adjust as needed.

Though sewing machines require regular maintenance, the steps for inserting and cleaning the Janome sewing machine needle are simple and easy to remember. With just a few steps and supplies, you can have your machine ready to go in no time.

Types of Janome Sewing Machine Needles

There are a variety of needles available for Janome sewing machines, each designed for a specific fabric and project. Universal needles, for example, offer medium point and are designed to sew a variety of fabrics and weights. These are good for general sewing and craft projects.

Ball point needles are great for knits such as cotton and jersey, as the ball-point end will not catch and damage the fibers. Embroidery and quilting needles, on the other hand, have special features to help keep stitches even and to handle multiple layers of fabric. Microtex needles, on the other hand, are sharper with a finer point, making them ideal for sewing light-weight fabrics and for top-stitching detail.

When selecting a needle for you project, the best approach is to read the label. Many needles also have color coding, with a small colored band on the shaft above the eye indicating the needle size and type.

Janome Sewing Machine Needle Troubleshooting

Though inserted instructions should keep your machine running smoothly, if you experience any problems with the needle, there are a few simple steps you can take to troubleshoot. Start by inspecting the needle to make sure it’s in good condition. If its bent or damaged, a new needle may be in order. The tip of the needle may also show signs of wear, which can affect the stitch quality.

It’s also important to check the needle thread tension. If the tension is too tight or too loose, it will affect your stitches. Make sure you’re using correct type and size of needle for your project. If the needle is the wrong size for the fabric, the stitches will be too loose, resulting in uneven tension. Always check the owner manual for the best needle for your project.

Finally, make sure the needle is properly inserted and secured into the clamp at the top of the machine. A loose needle can result in stitches that are inconsistent or skipped. If you need to insert a new needle, follow the steps outlined in this article to thread the new needle.

How to Make Necessary Adjustments to the Janome Sewing Machine

Most sewing machines come with options for adjusting the speed, tension, and stitch length. Making adjustments can make a big difference in the quality of your stitches. Different tasks require different settings, so it’s important to familiarize yourself with the adjustments.

To adjust the stitch length, look for the dial or knob on the side of the machine. Most machines will allow you to make adjustments from 0.5 mm up to 4 mm, depending on the type of fabric you’re using. For thin fabrics, shorter stitch lengths are recommended; for thicker fabrics, longer stitch lengths works best.

Another adjustment you can make is the tension. On most machines, you’ll find a small knob labeled “tension” on the top or side of the machine. Generally, lighter fabrics require less tension while heavier fabrics require more. Dial in the appropriate setting to make sure the bobbin thread isn’t too tight or too loose.

Finally, adjusting the speed of the machine can help you manage larger, more intricate projects. Most machines come with a speed control lever or a pressure-sensitive foot control that limits the maximum speed. It’s best to practice on scrap fabric first with different settings until you find the best speed for the current project.

Maximizing Comfort When Using the Janome Sewing Machine

When it comes to using the Janome sewing machine, comfort is key. Working for long periods with your sewing machine can be uncomfortable and can lead to fatigue and frustration. To help make the experience more enjoyable, there are few easy steps you can take to maximize comfort.

For starters, adjust the height of the machine to your sitting position. Many machines come with adjustable feet, which will allow you to elevate the machine to the level of your chair. You should also adjust your chair so your feet are flat on the floor and your knees are bent at a 90-degree angle.

It’s also important to make sure you’re sitting with your back straight and your arms relaxed at the side of your body. Adding a footrest can allow you to move your feet up and down while sewing, which will help give you more stability and control over the machine.

Finally, consider a sewing chair with arm rests. Arm rests can help reduce fatigue and improve posture. Look for one that swivels, so you can turn the chair as needed for sew for longer periods of time.

Tips for Troubleshooting Most Common Janome Sewing Machine Issues

Though the Janome sewing machine is a reliable and versatile machine, problems can still arise from time to time. Here are some of the most common problems and tips for troubleshooting:

Thread bunching: check the machine’s tension, clean the lint and dust, and try a different thread. If the problem persists, you may need to replace the thread.

Skipped stitches: check the needle size, make sure the thread is coming from the spool correctly, and ensure the presser foot is even.

Tension issues: check the needle size, clean the machine of any lint or dust, adjust the tension and test the stitches, and check the threading path of the upper thread.

Bobbin jamming: check to make sure the bobbin is inserted correctly, the thread is wound correctly, and check the tension screws. You may also need to clean the bobbin case to remove any debris.

If the problem persists, it’s always best to seek advice from a professional before attempting to make any repairs on your own. Taking care of your machine is important for it stay functional and running continuously.