Understanding the Basics

Having the right tension on your sewing machine is essential to make sure your stitches look the way you want them to. Incorrect tension can cause puckering and loose stitches, but working with the right tension is not only easy but also immensely satisfying. The tension setting on a sewing machine regulates how much thread is used to stitch a stitch and determines the length of each stitch.

The first step to learn how to get the right tension on a sewing machine is to understand the basic functions. A sewing machine has two spools of thread, one located in the top and the other located in the bobbin casing. This is where the tension is found; when more tension is applied to the thread, it pulls tighter and makes longer stitches. In the event that too much tension is applied, the stitches will be too tight and will cause the fabric to pucker.

Check the Manufacturer’s Instructions

The second step to get the right tension on a sewing machine is to check the manufacturer’s instructions for your particular model. Every type of sewing machine may require a slightly different tension setting and the manual usually highlights these settings. It is also important to note that some machines may have slightly different settings for different fabrics or thread weights.

It is also important to make sure that the tension settings have not been adjusted from their original settings from the factory. This can be done by turning the tension dial to the highest number and then slowly decreasing the setting until the stitches are even. This will ensure that the tension is set at the proper level.

Testing Different Tension Settings

Another tip to getting the right tension on a sewing machine is to test different tension settings with a variety of fabrics and thread weights. By testing different settings, you can determine which one is best for the project you are working on. It is also a good idea to test your machine tension by stitching a few samples before starting an actual project.

It is also a good idea to practice tension adjustment on scrap fabric before beginning a project on the actual fabric. This is a great way to learn what tension settings work best for different fabrics and thread types. This will help you save time, money, and heartache from ruining a project due to incorrect tension.

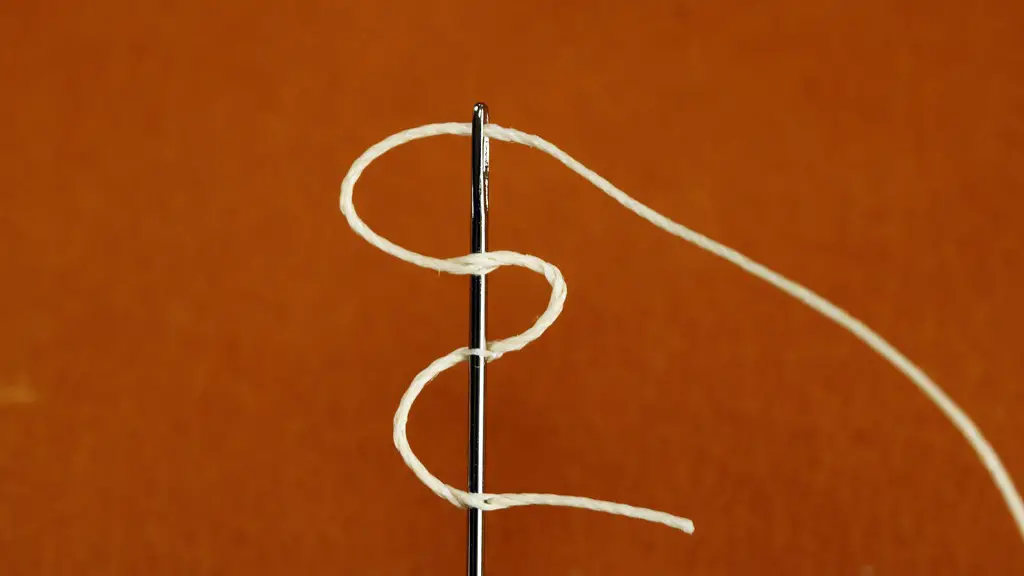

The Thread Is the Key

When it comes to achieving the correct tension on your sewing machine, the thread is the key factor. Different fabrics and threads can require different tension settings, so it is important to choose the appropriate thread for the fabric. A heavier thread will require more tension than a lighter one.

It is also important to remember to use the same type of thread in both the upper and lower spools and to ensure that the thread is unwinding from the spool in the same direction as the arrow indicates. Using the same type of thread ensure that the tension settings can be adjusted properly.

Always Check Your Tension

The key to getting the right tension on a sewing machine is to always check the tension after each stitch. This will help you to avoid major mistakes by ensuring that everything is running smoothly. Checking the tension when you start a project, after a few stitches, and at the end of the project will help to make sure the tension is consistent throughout.

In addition to checking the tension settings, it is also important to check the stitch length. Seam allowances need to be consistent, and the seam needs to roll smoothly. If the seam allowance varies, the tension may need to be adjusted as well as the stitch length.

Maintaining the Machine

Maintaining and properly servicing the machine is also important to achieving the correct tension settings. A sewing machine should be serviced at least once per year to ensure that all the parts are functioning properly. It is also important to regularly clean the bobbin area and check the needle for any signs of wear or tear.

Having the correct tension settings on a sewing machine will help you create perfect stitches every time. If the tension settings are not correct, it can lead to puckering, skipped stitches, and uneven seams. Taking the time to learn how to adjust the tension correctly and regularly maintaining the machine will ensure that your stitches are as smooth and consistent as possible.

Practice Makes Perfect

Adjusting the tension on a sewing machine is an acquired skill and can take some practice and patience. It is important to practice adjusting the tension on scrap fabric before starting a project. This will help you to become familiar with how the machine works and to gain confidence in the tension settings.

Practicing tension settings can also help you become more familiar with how different threads and fabrics require different tension settings. This will help you to become more proficient in adjusting the settings quickly and accurately.

Additional Tips and Tricks

When adjusting the tension on a sewing machine, it is a good idea to start by setting it at its midpoint setting. This will help to provide the most consistent stitch length and tension. It is also a good idea to use a seam ripper in order to adjust the tension if it is not quite right. This will help to avoid puckering and other tension issues.

Finally, it is important to remember that some fabrics require a slower or faster feed rate in order to achieve the correct tension. If the fabric is not feeding correctly, it will cause the tension to be off. By adjusting the feed rate and using the right type of thread, it is possible to achieve perfect tension on a sewing machine.

Seam Allowance and Thread Weight

Seam allowance and thread weight can also have an effect on achieving the proper tension. Very narrow seams and lighter threads may require more tension, while wider seams and heavier threads can require less tension. Experimenting and testing are key to getting the best tension settings for every fabric and every project.

Certain fabrics, such as rayon, chiffon and silk, can require a different tension setting than heavier fabrics such as denim or canvas. Taking the time to test different settings for each fabric can help to ensure that the machine is producing the desired stitches at the correct tension.

Alternative Tension Adjustment Techniques

Beyond adjusting the tension dial, there are several other techniques that can help to achieve a perfect tension. Adjusting the tension discs or plates located inside the bobbin case can be helpful in some cases. The stitch length can also be adjusted to achieve the desired tension.

Pre-wound bobbins are also an option to help with tension problems. Using a pre-wound bobbin eliminates the guesswork involved in winding bobbins and can help ensure that the thread is running properly.

Keep Track of Your Settings

Once you have determined the proper tension settings for your sewing machine, it is important to keep track of them. Keeping a log or notebook of the different tension settings for each project and type of thread can help to save time in the future. This will help to avoid having to re-adjust the tension for the same project or for the same type of fabric and thread.

Finally, it is important to remember that practice makes perfect. With a little patience and practice, it is possible to master the tension settings on a sewing machine and create perfect stitches every time.