Installing a sewing machine needle may seem like a daunting task, but it’s actually quite simple! Just follow these easy steps and you’ll have your needle installed in no time.

The following is a guide on how to install a sewing machine needle:

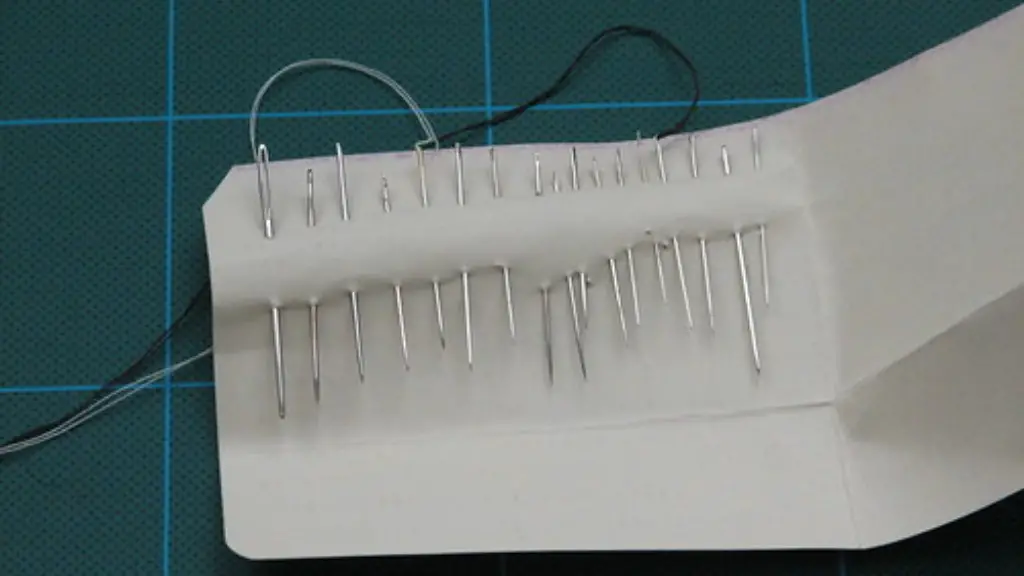

1. Firstly, identify the size and type of needle that is required for your sewing machine.

2. Insert the needle into the needle clamp, making sure that the flat side of the needle is facing the rear.

3. Tighten the needle clamp screw to secure the needle in place.

4. Thread the needle according to your sewing machine’s specifications.

5. Raise the needle to its highest position by turning the handwheel.

6. Draw the thread through the needle eye from the front to the back.

7. Lower the needle into the fabric by turning the handwheel, and begin sewing.

Which way does the needle go in a sewing machine?

The scarf is the portion of the needle that extends beyond the shaft. It helps to guide the thread and prevents it from slipping off the needle. The direction of the scarf (left or right) is determined by the way the needle is inserted into the sewing machine.

The flat side of the needle should be facing toward the back of the machine. Make sure it is all the way up in the needle clamp, then tighten the needle clamp screw securely.

Should needle face up or down

Injecting towards your heart helps to ensure that the needle goes into the vein and not through it. Putting the needle into the vein at an angle with the hole of the needle facing upwards also helps to prevent going through the vein.

The bevel is the opening to the needle. The inside of the needle is called the lumen.

Do all sewing machine needles have a flat side?

The shank of a needle is the part that is inserted into the machine. The needle shank must be the right shape for your machine. Needles for home sewing machines often have a shank with one flat side and one rounded side for proper positioning. Commercial or industrial needles can have grooved, threaded or round shanks.

The spool thread comes from the top of the machine and goes through the upper thread guide, while the bobbin thread is under the needle and goes through the bobbin thread guide. This is how the two threads are kept separate and why the top thread is always on top of the bobbin thread.

How do you put the needle back in a Singer sewing machine?

Take a new needle with the flat side to the back and insert it in the needle clamp Once it’s up as far as it will go, twist it to the left and pull it out. If it’s inserted correctly, the needle will be facing to the right.

This is important because if you don’t insert the needle into the vein at the right angle, you could end up missing the vein entirely and injecting into the surrounding tissue, which would be very painful.

Do needles go all the way in

When giving a shot, it is important to place the syringe at a 90-degree angle to the shot site. The needle should stand straight up from the skin and quickly jab the needle all the way into the skin.

To start sewing, you will need to thread your needle. Pull your thread down toward the sewing machine needle, and thread the eye of the needle from front to back. Keep pulling the end of the thread until there are several inches of thread through the needle.

How do you attach and replace a needle?

There’s a screw up here on the top that needs to be turned to the left in order to loosen the needle. Doing so will give you better access to the needle and make it easier to work with.

You want to just push the button in until it stops. More pressure is needed to compress the air until the little ceiling is hit. That will give you the best results.

Do all needles fit all sewing machines

It is important to know that sewing machine needles are standardized. This means that they are compatible across the range of brands, including Janome, Brother, Husqvarna, Elna, Pfaff, etc. This is important to know because it means that you can easily find the right needles for your machine, regardless of the brand.

Stretch needles have a less rounded point than ballpoint needles, which makes them ideal for use with highly elastic fabrics like spandex and lycra. The eye and scarf of a stretch needle are specially designed to prevent skipped stitches.

Why does the thread keep breaking when I sew?

Threads can break if your needle is not inserted properly. Make sure the eye of the needle is facing the front (not slanted) and that the scarf (indent) of the needle is facing the back. Burrs in the needle may also cause the thread to shred. It’s also important to check up on your needles from time to time.

Right-handed threads run clockwise, and left-handed threads run counterclockwise. The origin of a thread’s handedness is rooted in human physiology: Screws with different handedness are ergonomic for people depending on their dominant hands.

Final Words

There is no one-size-fits-all answer to this question, as the process for installing a sewing machine needle can vary depending on the specific make and model of machine. However, in general, the process generally involves threading the needle through the machine’s needle bar, then placing the needle in the needle clamp and tightening it in place. For more detailed instructions, it is advisable to consult the machine’s manual or an online tutorial.

The process of installing a sewing machine needle is relatively simple and only requires a few supplies. First, gather the necessary supplies including the new needle, a flat-head screwdriver, and a pair of needle-nose pliers. Next, remove the old needle from the sewing machine using the flat-head screwdriver. Be careful not to lose the small spring that is beneath the needle. Once the old needle is removed, take the new needle and insert it into the sewing machine, making sure that the flat side of the needle is facing the back. Finally, use the needle-nose pliers to secure the needle in place and reattach the small spring.