How To Install Walking Foot On Brother Sewing Machine

If you want to take your Brother sewing machine to the next level, you should consider installing a walking foot to your machine. Walking feet are ideal for quilting and sewing multiple layers of fabric or canvas, as well as for attaching various fabrics together for garments and items like curtains and cushion covers. This guide will take you through the steps necessary to install a walking foot on a Brother sewing machine.

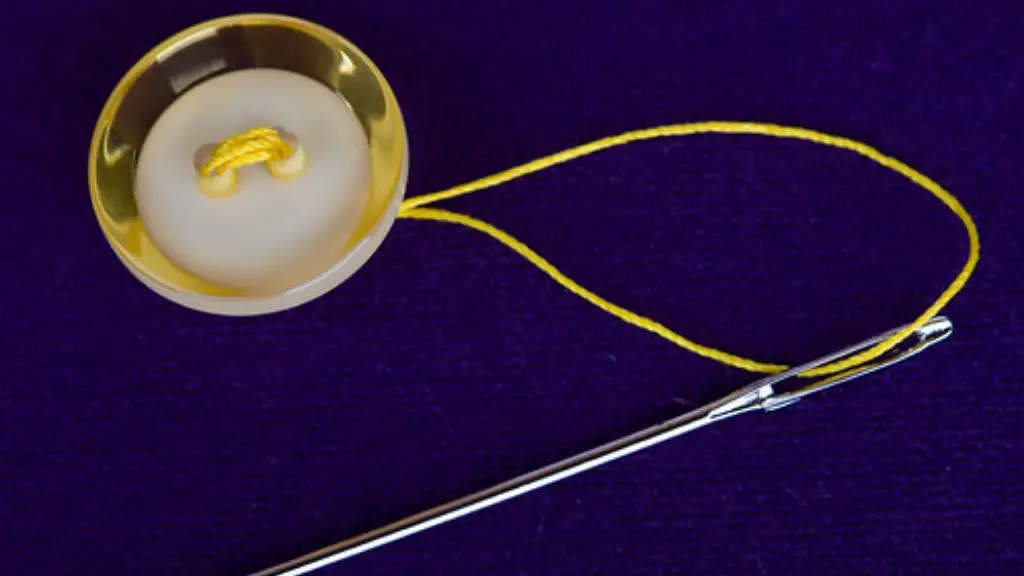

One of the most important things to do before beginning the installation process is to make sure you have the right size walking foot for your Brother sewing machine. You can find the walking foot size in the machine’s manual or by looking at the foot. The size should match the needle bar of your Brother sewing machine. It’s critical to get the right size walking foot, as a sloppy fit can cause thread tangling and skipped stitches.

Begin the installation process by first loosening the screws that hold the walking foot to the machine. Next, insert the foot in the holder and then re-tighten the screws. This helps ensure that the walking foot fits on the machine properly and is secure. Be sure to tighten the screws until they are secure, but not overly tight.

In addition to the walking foot, you may also need a walking foot adapter. This is a metal plate that helps the foot move smoothly on the fabric without slipping. The adapter plate also helps to support the weight of the walking foot and ensures it is not pushed up or down. This can make a huge difference when it comes to the overall performance of your Brother sewing machine.

Before using the walking foot for the first time, practice using it on scraps or spare fabric. This is a great way to get familiar with the new foot and the overall look and feel of your machine. Once you have a handle on things, you can start stitching up any project you have on the agenda.

If you ever experience issues while using the walking foot on your Brother sewing machine, check the feed dogs to make sure they are clean and free of any debris. This is important as it helps to ensure the smooth path of the fabric going through the machine. If the feed dogs are dirty, carefully clean them and then make sure the screws are tightened on the walking foot. This will help the walking foot work effectively on any project.

Finally, it’s important to remember to oil your machine regularly. Not only will this help to keep your machine running smoothly, but it can also help to prevent any issues with the walking foot. If you need help with any of the steps in this guide, make sure to consult your machine’s manual or a qualified professional for assistance.

Steps for Removing a Walking Foot

When it’s time to remove a walking foot from a Brother sewing machine, there are a few easy steps to follow. First, loosen the screws where the foot is attached to the machine. Then, carefully remove the foot, ensuring it doesn’t become bent or twisted. Once it is free, pull the foot off and re-tighten the screws.

If the walking foot needs to be cleaned, make sure to use a soft cloth to gently lift any dirt or debris. Once it has been wiped down, add a few drops of oil to the metal plates and then re-attach the foot to the machine. This is an important step, as it helps the walking foot to move freely and easily when sewing.

If you’re changing to a different style of walking foot, such as a roller or even-feed foot, follow the same steps for removal as outlined above. Make sure to use the same size walking foot for the style or type of fabric you’re working with, as the wrong size can cause skipped stitches or uneven feed.

Walking Foot Maintenance

It is important to take proper care of your walking foot by performing regular maintenance. This should include cleaning and oiling the foot, as well as removing any debris that may have collected in the holder. Make sure to inspect the foot regularly for any signs of wear and tear, as this could lead to problems such as skipped stitches.

In addition to cleaning, it’s important to check the walking foot for any mechanical issues. If the mechanism is broken or damaged in any way, it’s important to replace it as soon as possible. This helps to avoid any further issues down the line.

Finally, it’s also important to make sure the walking foot is properly aligned. This is done by using a small screwdriver to align the feed dogs with the needle bar. When the foot is properly aligned, it will move freely and easily on the fabric, ensuring the stitches are even and neat.

Tips for Installing Walking Foot on Brother Sewing Machine

When learning how to install a walking foot on your Brother sewing machine, there are a few tips and tricks to follow. First, make sure to check that the needles and the feed dogs are aligned properly. This helps to ensure the walking foot will not slip when sewing.

In addition to checking the alignment, it is also important to make sure the screws are tight and secure. Without the screws being tight, the walking foot can move when sewing and this can lead to skipped stitches and other issues. Tighten the screws, but not too tight.

It is also important to oil the walking foot before using it. This helps to keep the walking foot moving smoothly and prevents any issues with it sticking to the fabric. In addition, regular oiling of the foot can also help to improve its overall performance.

Finally, it’s also important to take time to practice using the walking foot. This can be done on scrap fabric or fabric that is not intended for a finished project. Practicing can help you to get more familiar with the foot, as well as how to move it and adjust the tension when sewing.

Difference between a Walking Foot and a Regular Foot

The primary difference between a walking foot and a regular foot is that a walking foot moves simultaneously in multiple directions. This is because it is attached to the machine’s feed dogs, which also move simultaneously. This means that the walking foot helps to evenly feed fabric and other material through the machine without any slipping or bunching.

A regular foot only moves in one direction and is actuated by a knob or lever on the machine. This lever helps to move the regular foot in a forwards and backwards motion to help with stitching and sewing projects. In comparison, a walking foot helps to evenly feed fabrics with ease, eliminating any slipping or bunching.

Another key difference between the two is that a walking foot is typically larger and bulkier than a regular foot. This is because the walking foot needs to be attached to the feed dogs, which are larger than a regular presser foot.

Finally, a walking foot is ideal for projects that involve multiple layers of fabric or heavier fabrics. This type of foot helps to move those fabrics through the machine without any slip or distortion. In comparison, a regular foot is ideal for lighter fabrics and for straight or zig-zag stitching on any fabric.

Benefits of Walking Feet on Brother Sewing Machines

There are a number of benefits to using a walking foot on a Brother sewing machine. First, it helps to keep the fabric moving through the machine without any slipping or bunching. This is ideal for sewing projects that involve multiple layers of fabric, such as quilting projects.

In addition, walking feet help to ensure even stitches when sewing. This means that the stitches are neat and evenly spaced, which helps to give projects a professional, finished look. It also helps to eliminate any unsightly puckers or gaps.

Finally, walking feet can also be used to topstitch fabric along edges, such as clothing or quilts. This helps to ensure the topstitching is even and doesn’t get bunched up along curves or other shapes. The walking foot makes this process much faster, as it helps keep the fabric moving through the machine smoothly.

Frequently Asked Questions About Installing a Walking Foot

Q: How long does it take to install a walking foot on a Brother sewing machine?

A: It should take around 10-15 minutes to install a walking foot on a Brother sewing machine. This includes finding the right size walking foot, loosening and tightening screws, and performing any other maintenance on the foot.

Q: Should I oil my walking foot?

A: Yes, it’s important to oil your walking foot regularly. This helps to keep the foot moving smoothly and prevents any issues with it sticking to the fabric.

Q: Is it difficult to install a walking foot?

A: It is a relatively simple process to install a walking foot on a Brother sewing machine. Just make sure to follow the instructions included in the machine’s manual and make sure the foot is the right size for your machine.

Q: Can I use a walking foot for all types of fabric?

A: Yes, walking feet are designed to work with virtually any type of fabric. However, it is important to use the correct size walking foot for that particular fabric and project.