Are you nervous about loading a bobbin on your Janome sewing machine? It’s actually quite easy once you understand the process. Different machines are slightly different, but these instructions should work for most models. All you need to get started is the bobbin of thread you’re going to use, as well as the scissors or tweezers to help you snag the thread.

First, word level the top tension disk, making sure that it is not too tight. If it is too tight, it can cause the machine to break. There are two knobs on the machine you’ll have to adjust. Then, turn the hand wheel toward the front side of the machine until you reach the spot just before the needle touches the fabric. Simply slip the bobbin on the bobbin case.

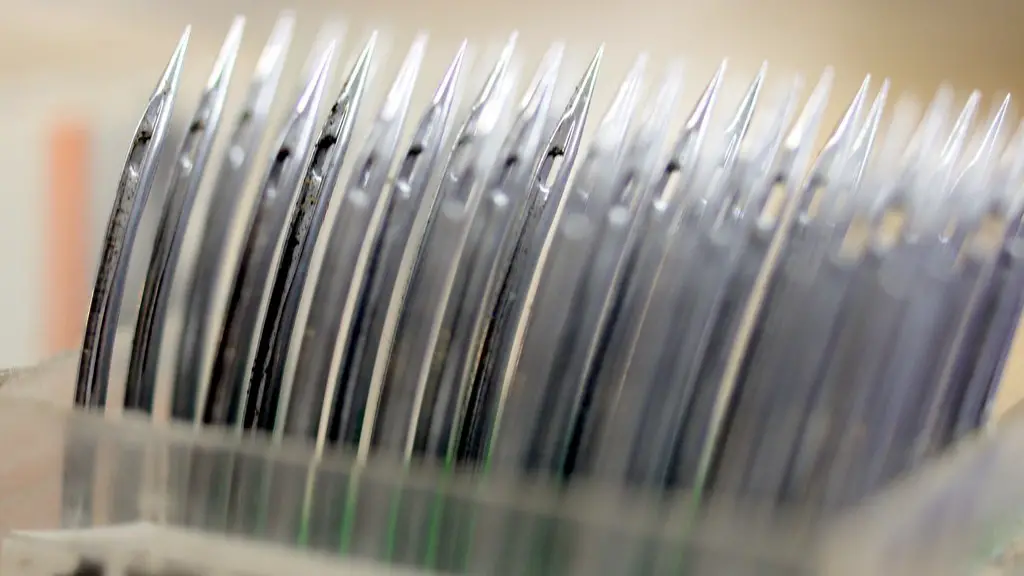

Before you thread, you’ll need to make sure that the bobbin is wound correctly. Look for the arrow on the side of the bobbin case, and make sure it is pointing to the right as you place it inside the machine. Make sure the thread is going clockwise, and that it’s wound evenly and not too full.

After you have the bobbin in place, the next step is to guide the thread through the slit in the bobbin case. Take your tweezers and grab the end of the thread and pull it through the slit. You’ll want to do this tightly, but don’t pull too hard as this could cause the thread to break. Once you get the thread completely through the slit, you’ll want to use the tweezers to grab the loose end and pull it back out, making sure to leave some of the slack in the thread.

Once the thread is all set, you need to pull the thread around the bobbin case, taking care not to cross the thread. Make sure the thread is smooth and not tangled. To test if everything is set up correctly, press the foot pedal and watch the bobbin spin, and make sure that it is spinning the correct direction.

Now it’s time to thread the machine. Pull a loop of thread through the take-up lever, located at the top of the machine. Then slowly guide the thread down to the needle as you turn the hand wheel. When you reach the needle, guide the thread through the first thread guide and then to the last. Then pull the thread up to the spool pin.

Once the thread is in place, you’ll want to take the thread and pull it out towards the right side of your machine, making sure it goes through the tension disks. The disks should remain the same level throughout the process. Then bring the thread back up to the take-up lever, and repeat the same instructions as before until all the thread is wrapped around the take-up lever.

Now your machine is ready to sew! Place your fabric underneath the needle and start sewing. You don’t have to do anything else with the bobbin until you run out of thread. All you have to do then is wind up some more thread and repeat the steps.

Caring for Your Bobbin

Once you get comfortable with your bobbin, you’ll want to be sure to take care of it. Clean it regularly with a dry cloth and be sure to avoid getting it wet. Replace the thread regularly to ensure quality stitching, and always make sure to keep extra bobbins handy in case one ever breaks.

You should also keep a few extra bobbins in case you need to switch out colors. To switch a bobbin, start by releasing the bobbin case and pulling it out gently. Make sure the new bobbin is wound correctly, and then place it in the bobbin case. Make sure the thread is going the correct direction, and then thread the machine in the same way you did for the first bobbin.

Once you’ve gotten the hang of it, loading and switching bobbins is a breeze. Just be sure to be gentle with the machine, and your stitches will be looking beautiful in no time!

Bobbin Troubleshooting

Sometimes your bobbin could get jammed or be set up wrong. If you find your machine is stuck or not sewing properly, the issue could be with the bobbin.

If the bobbin case is loose, this could be the result of repeatedly over-tightening the hand wheel, leading to the bobbin case coming loose. If this occurs, simply look for the screw at the bottom of the case and tighten it a bit more.

Another common issue is the thread becoming tangled or jammed, usually resulting from the thread being too loose or too tight. If you find that the thread is not being pulled up properly, try re-adjusting the tension disks.

Finally, if the thread is still not pulling up correctly, it could be that the thread is not going through the guides correctly. Check the thread guides and make sure the thread is going through each one in the correct order.

If all else fails, it’s probably time to take the machine in for servicing. Bobbin issues can become very complex and you don’t want to risk damaging your machine.

Getting the Best Thread

Your sewing project depends largely on the quality of thread you’re using. If you want the best of the best, try looking for 100% cotton thread. This type of thread is strong and doesn’t stretch, meaning that it won’t wear down quickly.

You’ll also want to look for low-lint threads, as lint from the thread can cause clogs and jams. If you’re unsure about a thread, be sure to look for reviews from other sewers.

When it comes to colors, it pays to have as much variety as possible. Invest in a good selection of spools in each color so you’ll always be ready for any project.

Saving Money on Thread

Thread can start to add up, so if you’re looking to save a few bucks on your next project try buying online. There are many online retailers who maintain an ever-changing selection of thread and they often offer great deals that you won’t find in stores.

If you’re only working on smaller projects, try looking for pre-wound bobbins. These little plastic containers come with a bobbin already pre-wound and they’re perfect for quick repairs or small projects.

Finally, try buying in bulk. Many stores offer discounts when you buy in bulk, so if you’re a serial sewer you might want to check out your local fabric store for more discounts.

Reusing Thread

One of the best ways to save money on thread is to start reusing what you have. Reusing thread is easy, just make sure to keep your spools away from dust and dirt so they won’t get contaminated.

If you’re going to reuse a spool, start by pulling the thread off the spool and run it through a Few passes between your fingers. This helps remove any debris or lint and will make sure the thread isn’t caught up in any knots.

Once you’re sure it’s relatively clean, take the thread and wind it onto a new spool and use it to thread your machine. If you find your thread is still catching, try washing it with soap and water before re-winding it onto your spool.

Reusing thread is a great way to save money and reduce waste, so why not give it a try?