Industrial sewing machines play an important role in all stages of the apparel industry, and although they are quite durable and reliable, they require regular maintenance if they are to last long. Oiling your industrial sewing machine regularly will ensure that it keeps movements smooth and seamless, allowing for maximum production. This guide will explain the steps on how to properly oil an industrial sewing machine, and why it is so essential to its longevity.

The first step to oiling an industrial sewing machine is understanding the different types of oils that it requires. The most common type of oil for industrial sewing machines is mineral oil. This oil keeps the machine lubricated, ensuring that the mechanisms remain efficient and smooth. It also helps to prevent rust and corrosion taking place, prolonging the life of the machine. Depending on the model of sewing machine that you have, it is important to check the user manual to find out what type and grade of oil to use.

Before you oil any machine parts, it is important to make sure the machine is completely switched off and the power cord is disconnected. This helps ensure that no extra damage occurs while oiling. You should then cover the bed, table, or surface where the machine is resting. Make sure to use a protective surface such as a tray or a piece of cardboard. This helps protect the machine from any oil spills and/or dirt.

The next step is to remove the machine covers and any other exterior sections to access the inner workings of the machine. Refer to the manufacturer’s documentation to work out the machine’s mechanical and electrical wiring. This will come in handy when oiling, as you can easily access the parts that need to be lubricated.

Once the covers are off, you need to identify the parts that require oiling and apply it one drop at a time. As a rule of thumb, make sure not to over-oil the parts, as this can lead to a buildup of residual oil that can damage the parts. Also, make sure to oil the parts that are in direct contact with moving parts, as this will help keep them continually lubricated.

Once the parts have been adequately lubricated you can then start to put the machine coverings back in place. When installing the sections, ensure that the bolts or screws are adequately tightened as this helps protect the interior workings of the machine.

Finally, when oiling an industrial machine it is vital to clean it regularly. This is important as any dirt and debris can accumulate over time and cause the machine to jam. Make sure to use an old toothbrush or small brush to clean any excess dust or dirt from the areas which have been oiled. It is also recommended to lubricate the shuttle assembly, the arm and thread plate area and the bobbin winding mechanism.

Sewing Threads

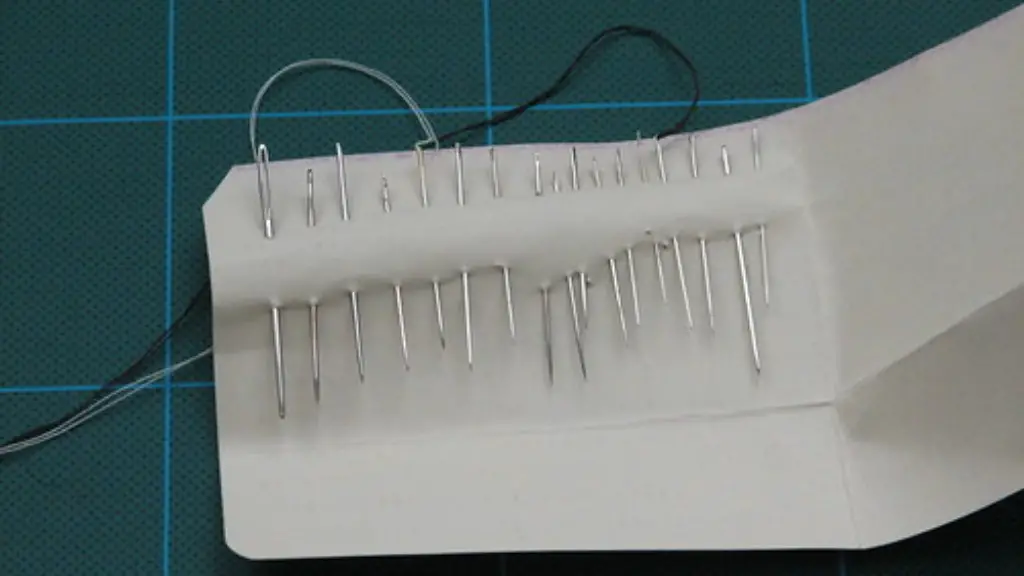

Sewing threads also play an important role in ensuring that the industrial sewing machine functions properly. It is important to always use the correct type of thread for each application. Different fabrics and materials require different types of threads, such as cotton thread, polyester thread, nylon thread, and polyester-cotton blended thread. Additionally, each type of thread has a different gauge, which should be considered when selecting a thread.

When winding the bobbins it is important to select a thread that is the same or closest to the size of the needle. This will help ensure that the thread glides smoothly through the fabric and the machine. Additionally, it is important to regularly check for worn or broken threads, as this can affect the machine performance.

Stitching Settings

Once the machine is properly lubricated and the correct thread is chosen, the final step is to set the stitching settings. Different fabrics will require different stitching settings in order to ensure optimum performance. Make sure to refer to the manual of your machine or the fabric supplier to properly adjust the settings based on the fabric being worked with. Generally, the settings should include the stitch length and width, the type of stitch, the tension of the thread, the presser foot pressure and other details.

Troubleshooting

If, at any point during the sewing process, the machine jams or produces irregular stitching it is important to troubleshoot the issue. Ensure that the machine is correctly threaded and that the tension of the thread is correctly adjusted. Additionally, check that the parts of the machine are correctly lubricated, and that the correct stitch settings have been chosen for the fabric.

Finally, it is important to have a regular maintenance schedule for the industrial sewing machine. Check the user manual to find out what the recommended maintenance schedule and oiling intervals are for your specific machine. This will help ensure the machine continues to perform optimally for years to come.

Preventative Care and Maintenance

Preventative care and maintenance are important if you want your industrial sewing machine to run smoothly and effectively. Regularly clean the machine parts with a soft cloth or brush to remove any dirt and debris. Additionally, cover your machine when not in use and make sure to oil the parts before and after every use.

Also, make sure to regularly check any belts, moving parts and needles. Make sure they are tight and that the tension of the thread is correctly adjusted. Finally, keep all machinery manuals and other related documents in a safe and secure place for quick reference.

Attending seminars and courses is an excellent way of becoming an expert at operating an industrial sewing machine. Such seminars are usually run by experienced professionals and provide valuable insights into proper maintenance, machine operations and best practices.

You will also have the opportunity to ask questions and gain practical experience. Furthermore, attending seminars and courses can be a great way of networking with sewing machine experts and gaining valuable connections. Most importantly, seminars and courses allow you to stay current with the latest technologies and trends within the sewing industry.

Replacement Parts

Although industrial sewing machines are quite reliable and hard wearing, every now and again it is necessary to replace some of the parts due to wear and tear. Therefore, always keep a spare set of parts on hand, including needles, thread, oil, shuttles and other small parts. Additionally, if you find that a part is faulty or worn, make sure to replace it as soon as possible.

We recommend sourcing your replacement parts from the same manufacturer as the machine. This will ensure that you get the right parts with the correct fit and specifications. Moreover, parts from a legitimate source also ensures that you get good quality parts that are designed to last.

Safety Tips

Finally, it is important to always observe safety when operating an industrial sewing machine. This includes ensuring that you are wearing appropriate protective clothing, such as gloves and a muzzle. Additionally, make sure that the area around the machine is well lit and free from any obstacles or hazardous materials.

Keep the power cord away from any liquids, puddles and other potentially hazardous materials. Furthermore, make sure that each bolt or screw is correctly tightened in order to ensure the proper functioning of the machine. Finally, never attempt to repair the machine by yourself, instead ensure that only qualified personnel undertake any repairs or maintenance.