1. Stringing the Bobbin Case

To begin with, you need to get the string wound around the spool of thread that’s located at the top of the sewing machine. Unwind the spool and pull out some of the string – this should be enough to stretch around the bobbin case and the whole length back to the spool. Some sewing machines require you to use their own type of thread – make sure to refer to the instruction manual to see what kind of thread you should get.

Once you have the string, locate the bobbin case, which looks like a rounded dome projecting from either the side or the back of the sewing machine. Take the loose end of the string and wrap it around the bobbin case. Wind it around about five times until there’s no slack in the string that’s wrapped around the bobbin case, then begin winding the string back to the spool.

Make sure that the string is wound around the bobbin case in the same direction and at the same tension as the string on the spool – this is so that the machine won’t get tangled up and start unraveling. Keep wrapping the string back to the spool until the bobbin is fully loaded with a few inches of string left over. Secure the loose end of the string onto the bobbin with a flat screwdriver to prevent it from coming loose.

2. Setting up the Thread Guide

Once the bobbin is ready and loaded with thread, the next step is to thread up the sewing machine. Take the spool of thread and move it to the thread guide, which is usually at the top of the machine – the thread should sit in the guide with no slack or drag on the string. Tighten the tension on the thread guide, so it holds the spool of string in place.

Then, take the string from the spool and run it through the rest of the thread’s guide – from the bobbin case, up to the needle and then through the thread guide on the top of the machine. Pull the string up to the needle until a few inches of thread are showing – this is so you can thread the needle with the string.

3. Threading the Needle

At this point, the machine should be ready to start sewing. But before you begin, you must thread the needle. Lift up the presser foot before you do this and pull up on the thread to make sure it’s not too tight or too loose.

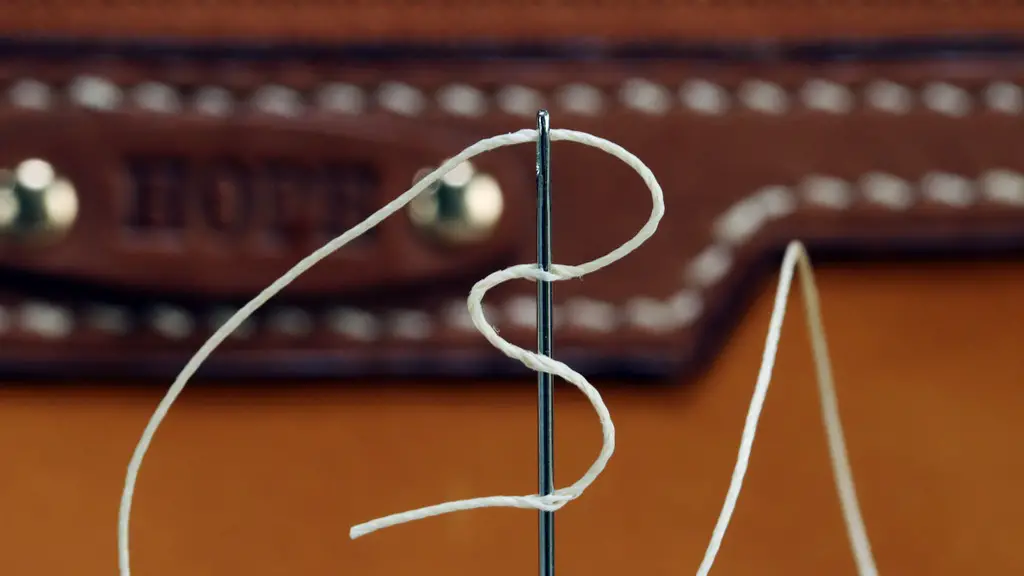

Then, take the loose frayed end of the string and pass it through the hole at the top of the needle. Feed the thread through the hole until it comes out at the other side and pass it down the back side of the needle. Make sure the loose end of the string is several inches long; this allows the machine to sew without tangling the thread.

4. Thread Tension Adjustment

Once the needle is threaded, you’re ready to begin sewing. But first, there’s the important step of adjusting the tension on the string. This can be a tricky process and if the tension isn’t set right, the stitches won’t come out even.

To adjust the string tension, turn the knob on the top of the sewing machine to loosen or tighten the thread. Try a few practice stitches to see how it looks and keep adjusting the tension as needed until the stitches are even and free of tangling. Once the tension is adjusted, you’re ready to start sewing!

5. Troubleshooting

Even if you take all the necessary steps to make sure the string is in the right place and the tension is set properly, it’s still possible for knots to start popping up in the stitches. This can happen if the string is too loose or too tight, or if it’s misaligned in the machine.

If you find yourself struggling with knots and jams in the stitching, try tried-and-true troubleshooting methods such as realigning the thread, using stronger tension, using a different type of string, or making sure the bobbin is wound correctly.

6. Tips and Tricks

Putting string in the machine isn’t always straightforward, so here are some tricks to help you out.

First off, make sure you use the right kind of thread for your machine – some of them require a specific type of thread that’s designed for the sewing machine. Make sure to check the instruction manual for this piece of information. When winding your string, make sure it’s wound in the same direction and at the same tension as the string on the spool.

Also, take the time to adjust the thread tension correctly, as this will save you a lot of trouble if the project you’re working on requires even stitches. Finally, if you ever encounter tangles or knots, make sure to realign the thread, check that the tension is correct, and use the troubleshooting methods mentioned above.

7. Upkeep and Maintenance

Regular upkeep and maintenance of your sewing machine will go a long way towards keeping it functioning properly. Every couple of months, make sure to inspect your machine and check for any damages or wear-and-tear that could be causing problems. Regularly oil and lubricate any moving parts, and take the time to clean out any dirt or dust that may have accumulated in the components.

Just as importantly, make sure the string is always in good shape. After every project, take the time to wind it back up properly and check for any fraying or damage that could affect the quality of the stitching.

8. Different Types Of Thread

When it comes to stringing the machine, you should choose the type of thread to use carefully. Most sewing machines require specific types of thread, such as cotton thread, polyester thread, or metallic thread.

Cotton thread is the most common type of thread, and it’s strong and durable. It’s recommended for use on light to medium fabrics, and it’s ideal for hand stitching due to its flexibility. Polyester thread is strong and resistant to shrinkage and fading, making it a great choice for sewing on heavier fabrics. Metallic thread, on the other hand, is great for decorative work and adds a bit of sparkle and shine to any project.

9.How To Choose The Right Thread

When choosing a thread, it’s important to keep in mind the type of fabric you’ll be using. Heavier fabrics require stronger thread, such as polyester, while lighter fabrics can use cotton thread. Also consider the weight of the thread – the heavier the thread, the more visible the stitching will be.

Make sure you also take the color of the fabric into account. Always try and use a thread that’s close to the color of the fabric and the color of the thread should be darker than the fabric, so that it doesn’t show up too easily.

10. Different Types Of Needles

Needles play a vital role in creating a high-quality stitch, so it’s important to choose the right type of needle for the fabric you’re working with. There are a variety of needles available, including ball-point needles, embroidery needles, and universal needles.

Ball-point needles are designed specifically for knit fabrics, while embroidery needles are designed to work with heavier fabrics. Universal needles can be used on a wide variety of fabrics, so they’re a great choice for projects with multiple types of materials. Make sure to consult the instruction manual to make sure you’re using the right type of needle for the job – it’ll help you create a stronger and longer-lasting stitch.