Can’t remember how to thread a bobbin on a Janome sewing machine? Here’s a handy guide to make sure you never have to deal with that head-scratching moment again.

Threading the bobbin on a Janome sewing machine is an essential skill for everyone with an interest in sewing. Not only essential for creating the perfect stitch, setting up the bobbin the right way is essential for keeping the machine running smoothly.

But getting it wrong can spell disaster! Think wayward stitches, knotting, tangles… no one wants that.

1. Prepare the Machine

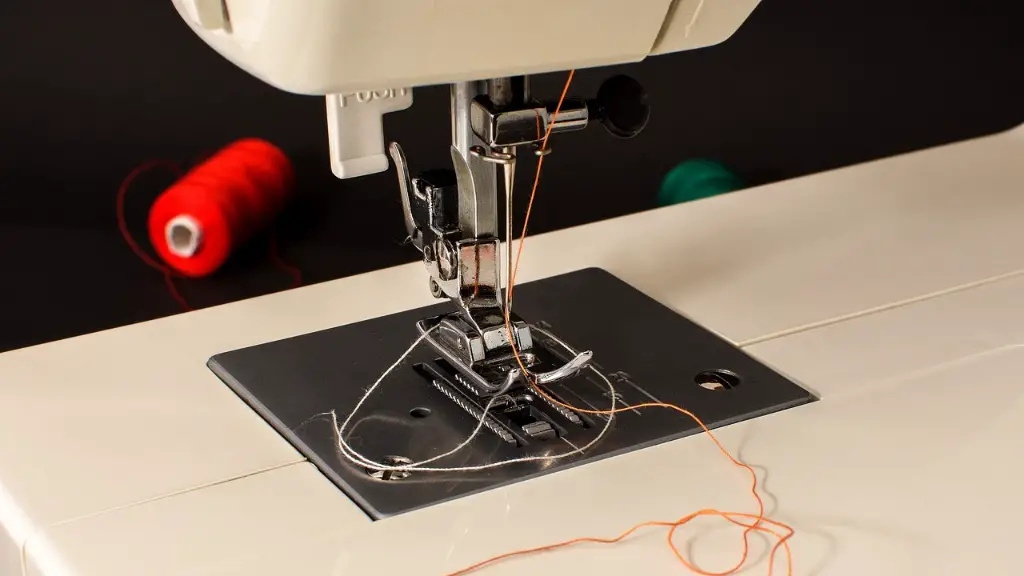

Before threading your Janome, it’s important to make sure the accessories are correctly installed and the thread is set correctly. Check that the presser foot is in position, the foot controller is connected, and the machine is correctly wound.

Next, thread the take-up lever and make sure the spool pin is set correctly. Now you can prepare for bobbin winding.

2. Lifting the Cover Plate

Lift the cover plate before inserting the bobbin and sliding it into the bobbin case. The cover plate should be hinged away from the machine to allow the bobbin to be loaded.

If your Janome has a separate bobbin threader, make sure to use it to feed the thread into the bobbin case. Then, place the bobbin in the machine, with the yarn pointing to the right.

3. Winding the Bobbin

Once the bobbin is in place, the next step is to wind the yarn around the bobbin. To do this, engage the bobbin winding mode by pressing and holding the bobbin winding button and then turn on the power switch. The bobbin should start winding automatically.

Continue winding the bobbin until the thread is snug and secure. When finished, press the bobbin winding button and turn off the power switch.

4. Inserting the Bobbin

Once the yarn has been wound around the bobbin, it’s time to insert the bobbin into the machine. To do this, press the needle down and then turn the handwheel counter-clockwise to raise the bobbin case. Then, pull the bobbin thread under the spring clip and lift up the needle plate.

Before inserting the bobbin, make sure to check if it is aligned correctly with the stem and that the end of the thread is wrapped around the bobbin. Push the bobbin into the machine, then close the needle plate and the bobbin should begin to move clockwise.

5. Threading the Bobbin

Now it’s time to thread the bobbin. You can use the spool pin to thread the needle or you can use the threader for a more precise job. With the spool pin, push the thread through the thread guide, then wrap it around the bobbin a few times. With the threader, insert the threader through the hole of the bobbin and pull the thread through the hole.

Once the bobbin is threaded, you can start to sew. Check that the bobbin is correctly positioned and that the thread is tensioned correctly before you begin.

6. Replacing the Bobbin

If you need to replace the bobbin, make sure it is the correct one for the machine. This is determined by the size and type of bobbin the machine requires. If you are using a plastic or metal bobbin, make sure it is the right length and diameter for your machine.

For some machines, you may also need to adjust the tension nut. Simply use a small screwdriver to adjust the knob and make sure the bobbin winding tension is correct. Make sure you rethread the needle when done.

7. Troubleshooting Common Problems

If you are having problems with threading your bobbin, there are several things to check. Firstly, check if the bobbin is correctly placed and if it is, ensure the thread is wound properly. Then make sure the needle is correctly threaded and the tension is adjusted correctly.

If the thread is still not winding properly on the bobbin, you may need to adjust the bobbin tension. For machines with thread tension disks, you can use the small screwdriver to adjust the disc and adjust the tension.

If the thread is still not winding properly, you may need to disassemble the machine and check if the bobbin winder shaft is misaligned. If so, check the manual for the correct procedure to align the shaft.

8. Tips To Prevent Problems

Finally, here are a few useful tips to help you avoid problems with your Janome bobbin winding. Firstly, make sure to use the correct type and size of bobbin as this can affect the tension. Also make sure the bobbin is correctly aligned in the sewing machine and that the thread is correctly wound on the bobbin.

It’s also important to regularly clean and maintain your bobbin winder to ensure it is free from dirt and lint. Then make sure you practice the process of loading and unloading the bobbin and wound the bobbin correctly.

9. Techniques to Make It Easier

When winding a bobbin on a Janome sewing machine, there are a few things you can do to make the process easier. Firstly, keep your machine well lubricated to reduce wear and tear. Then, use good quality thread and ensure the spool pin is correctly set.

Finally, practice loading and unloading your bobbin to ensure you understand the mechanics of the machine. Once you have mastered loading a bobbin correctly, it will become second nature and you can create perfect stitches time and time again.

10. Safety Precautions

It’s important to remember to use the safety mechanisms on your Janome sewing machines. These include a full-revolution power switch, operational lock-out mechanism and jog dial. The power switch should be in the off position when removing or installing a bobbin, and the operational lock-out can be a useful feature to reduce the risk of accidents.

Finally, make sure to read the manual and follow any safety instructions if you are unsure. And if you are having difficulty, don’t hesitate to get in touch with your local Janome dealer.

11. Bobbin Stitch Quality

The quality of the stitches depends not only on the correct setting of the threads but also on the correct tension of the bobbin thread. Too high or too low bobbin tension can affect the stitches and need to be adjusted.

After adjusting the needle tension and threading the bobbin, take some time to check the stitch quality. Look for skipped stitches and make sure the bobbin thread forms a nice loop on the underside. If not, adjust the bobbin tension until the stitches look perfect.

12. Cleaning the Bobbin Area

To ensure your Janome sewing machine is running smoothly, it’s important to keep the bobbin area of the machine clean. Make sure to regularly check the bobbin case and bobbin — if they become clogged with lint and dust, they can affect the tension or cause the thread to break.

If your bobbin needs cleaning, take it apart and check for dirt or lint. You can use a damp cloth, compressed air or a needle to remove any debris. Then, reassemble the bobbin case and the bobbin and test it on a scrap of fabric to make sure the thread tension is correct.

13. Bobbin Storage Tips

When storing your bobbins, make sure to store them in a dry, dust-free area. This is especially important for metallic bobbins as leaving them in a damp area for too long can cause them to rust.

Also, use a plastic container to store your bobbins and threads separately to avoid any tangling. And if you’re travelling with your Janome, use the special carrying case to ensure your bobbins and threads stay in perfect condition.