Most people don’t think about how complicated it is to get a sewing machine up and running, but it can be quite an involved process. Learning how to raise the presser foot on a Brother sewing machine is an important step and one that shouldn’t be skipped, as it’s essential to many operations. Many rookies trip up on this bit of the setup, so it’s important to understand the nuances.

Today, the process is much simpler than it once was, but that doesn’t mean it’s a no-brainer. This article will help break down the steps, making it easier for anyone to get their machine going with just a few simple steps.

Before attempting to raise the presser foot, make sure that you have powered on your machine. From there, it’s a matter of finding the appropriate control button inside the workspace. Most models have this within arms reach. If your machine doesn’t, you should check the user manual for guidance.

The control button should be labeled and resemble a raised foot. Place your finger firmly upon it and push it away from you. This activates the switch that seamlessly moves the presser foot into place. Most machines will click or beep in response to indicate that the foot has been successfully raised.

It’s worth noting that this process may differ depending on the model of machine being used. Some more modern models feature more automated features, including the ability to raise the foot with the touch of a button. Check your instructions to make sure.

Although it is a simple process, it is important to make sure that the foot has risen to the appropriate level for your specific machine. On some Brother models, this is about a 1/4″ gap between the foot and the material being used. If this isn’t correct, the machine won’t work properly.

It’s also important to make sure that the presser foot is adjusted correctly for the material you’re using. A good rule of thumb is to match the presser foot pressure to the fabric weight. For heavier fabrics, the presser foot should be set higher and for lighter fabrics, it should be set lower. This can be easily adjusted using the appropriate switch on the machine.

Preparing Your Machine For Sewing

Once the presser foot has been raised, it’s time to prepare the machine for the actual sewing. For this step, it’s important to make sure that the spool of thread is correctly loaded onto the machine. This involves a simple process of looping the thread around the bobbin twice, and then winding it around the spool pin below the bobbin case. Make sure that the thread is wound so that it doesn’t cross over itself.

Once the thread is installed, it’s time to insert the bobbin into the bobbin case in the machine. Depending on the model, there may be a small component required here. Make sure to check the user manual if you are unsure of how to do this.

Lastly, it’s important to load the fabric into the machine. Simply place it under the presser foot and adjust the size of the fabric to fit the presser foot. It’s important to note that the fabric should be facing the right way, with the right side facing upwards and the left side facing downwards.

Sewing With Your Machine

Once the presser foot is raised and the machine is ready, the next step is to begin the actual sewing. Make sure that the correct stitch is selected, as this will determine how the sewing will be done. Select a stitch that is suitable for the type of material you are using. Each stitch should be tested on a scrap piece of fabric before starting the actual project.

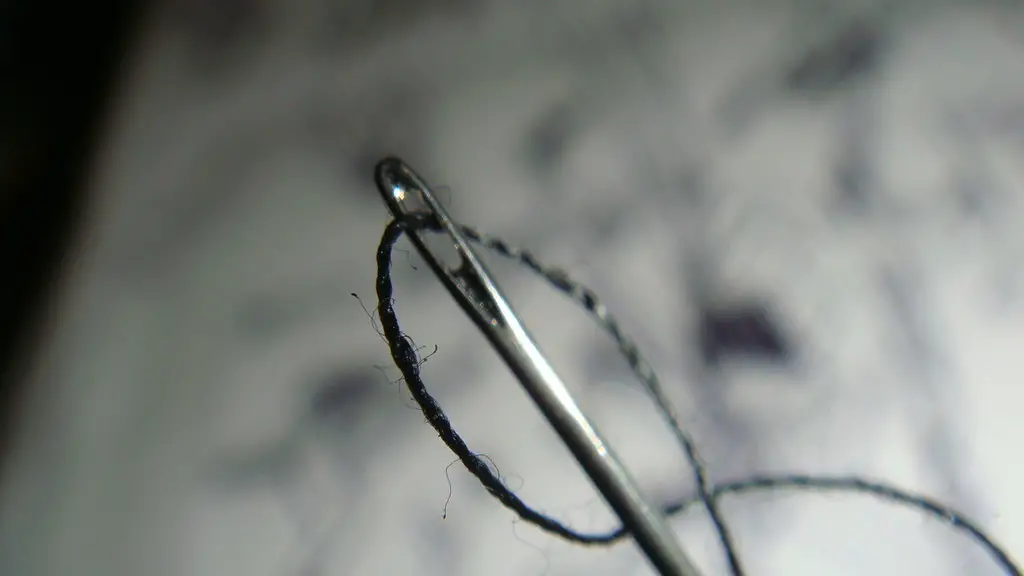

When you are ready, start to sew by pulling the thread from the back of the machine, as this will help ensure an even tension throughout the entire process. Once the thread has been extended to the front of the machine, push it through the eye of the needle and start the stitching by depressing the foot pedal.

Keep a steady pace and make sure that the needle is in the fabric before the sewing starts. A good rule of thumb is to place the needle in the fabric first, then engage the pedal. This is essential to maintain an even stitch and ensure that the fabric is securely in place.

Replacing The Needle

Almost as important as raising the presser foot is replacing the needle. This should be done periodically and as soon as the needle appears to be bent or out of shape. This is important as a dull or bent needle can cause uneven stitching, or even break the thread.

Replacing a needle is a simple process which involves unscrewing the cap at the top of the needle. Make sure to turn it counter clockwise. Once this has been done, open the needle clip, take out the old needle, then replace it with the new one.

Securely attach the new needle by pushing it all the way down until it clicks into place. The click is essential, as this is how you know that the needle is securely in place. With that done, simply reattach the cap, and your machine will be ready to sew with a brand new needle.

Using The Right Presser Foot

It’s also important to use the right presser foot when sewing with a Brother sewing machine. This is because each presser foot has its own purpose, and using the wrong one will not only make sewing difficult, but can also potentially damage the machine or the fabric.

For lighter fabrics, use a traditional presser foot, as this will make it easier to stitch. For heavier fabrics, an embedding presser foot may be necessary. If you are unsure of which presser foot to use, it’s best to consult the user manual for guidance.

Saving Your Stitches

Once the sewing is finished, it’s important to save any stitches that have been made, as this will make the process of hand sewing easier and will also help preserve the fabric. To save the stitching, secure each end with a knot, then use a double thread technique to ensure the stitches don’t come undone.

This should be done by passing the thread through the loop twice at the end of the row and pulling it tightly. This technique should be used when starting and ending a row of stitches, as it will ensure the stitches are securely locked in place.

Making Minor Repairs

Finally, it’s important to make sure that any minor repairs are done in a timely fashion. This includes making sure that any broken threads or needles are taken care of, as well as any loose or incorrect stitches.

To fix a loose stitch, start by taking out the bobbin case. This should be done carefully, as the thread is likely to be pulled or tangled if done too hastily. With that done, carefully untangle the thread, then reinsert the bobbin case and try the stitch again.

If more repairs are required, then refer to the user manual, as it will contain more detailed instructions on how to handle the situation. This could be in the form of a section dedicated to minor repairs, or it may be found in the troubleshooting section.

Storage & Maintenance

Storing and maintaining your sewing machine is also important to ensure that it continues to work properly. Keep it in a dry and dust-free environment and make sure to clean it after every use. Also, it should be oiled once every few months and serviced once a year.

When traveling, make sure to pack the machine carefully and keep it out of direct sunlight. It’s also a good idea to wrap it in