Removing a needle threader from a Brother sewing machine can be tricky and complex. For this job, you will need to understand how to work with the device and all of its accompanying parts and pieces. It is also important to wear safety goggles and gloves, as the needle on the machine can cause extensive damage to your eyes and hands. Before attempting to remove the threader, make sure that the Brother machine is turned off, the needle is in the stopped position, and the bobbin area is uncovered.

When ready, place the machine in a position that allows you to access the needle threader and have adequate light. With the needle threader in sight, gently press down on the bobbin section’s needle plate hook. While keeping the hook pressed down, hold down the needle threader’s holder lever and pull the threader away from the hook. This is the primary step for removing the threader on a Brother sewing machine.

Additionally, if you are having difficulty removing the threader, there are other methods you can use to get it off. First, if the threader seems stuck, try to press down on the back of the holder lever, as that may dislodge the part. Second, both the hook and threader may require cleaning – try using a soft cloth to wipe away dirt. Third, if mechanical issues persist, use a pair of needle-nose pliers to pull the threader away from the hook. Finally, if necessary, consult the Owner’s Manual or the sewing machine technician.

Reattaching the needle threader requires patience and precision. To begin, hold the threader at a 45°angle – this positioning is critical in the reinstallation process. Then slide the pointed end of the threader into the hook on the bobbin section, with the thread hole lined up with the hook opening. Finally, while keeping the threader at the given angle, press the holder lever forward until it snaps into place.

With the requirement of precision and a relatively small space to do the job, taking off and putting on a Brother sewing machine’s needle threader can be complex and time-consuming. To simplify the process, you can purchase small, 45°angled tweezers to both remove the threader and properly hold it for reinstallation. Furthermore, keep the machine well-maintained, as dirt and dust around the needle and threader can also cause problems.

Understanding Your Machine

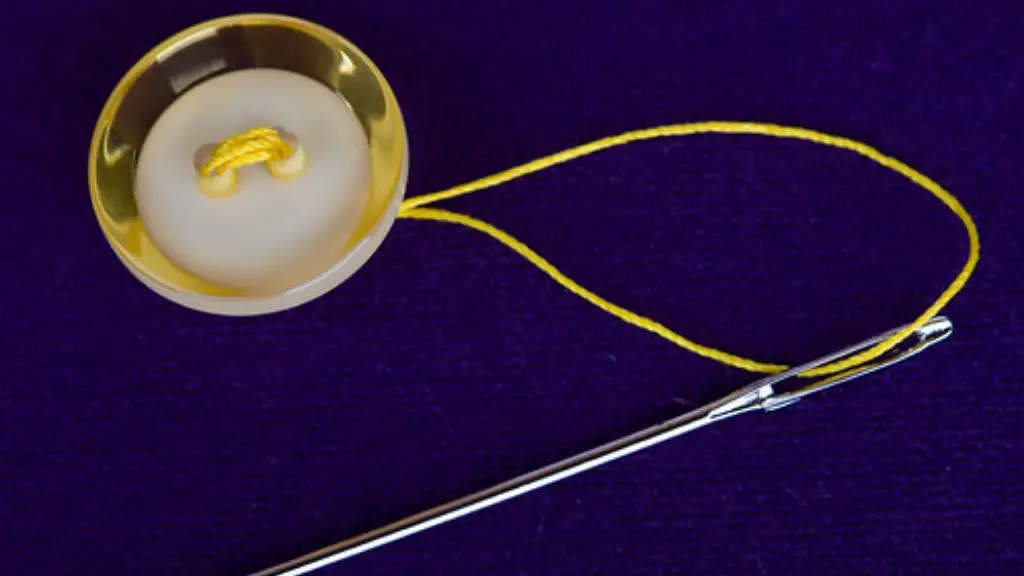

In any complex task, the first step is understanding the components and how they work together. When it comes to a Brother sewing machine, the needle threader is the mechanism which holds the thread and inserts it into the needle eye. It is a vital part of using a machine, as it is muh easier to thread the needle by simply using the threader.

In addition to knowing what the threader is, it’s important to understand the needle plate hook, bobbin section, and holder lever as well. These pieces are essential in the installation and removal process, so they must be handled correctly.

Moreover, be sure to distinguish between the various models of Brother sewing machines. Some of the company’s devices are the CS6000i and the XR3774. If a tutorial works for one of these models but not the other, it is likely because the threader has been differently designed. It is important to check the Owner’s Manual for a detailed description of the machine’s threader.

Safety Considerations

It is always advised to wear safety gear when working with a sewing machine, as the needle can cause significant injury. Although it is not possible to thoroughly protect oneself when handling the machine, it is still beneficial and necessary to put on safety goggles and gloves. Further, make sure that the needle and needle plate hook are both in the stopped position, meaning they are not in a ready-to-hook current.

As previously mentioned, it is also important to keep the machine clean. Dust and dirt can accumulate around the needle and threader, ultimately causing mechanical problems. Use a soft cloth to wipe away some of the dirt,, but be sure not to disrupt the placement of any parts. Finally, avoid using extra force, as doing so can damage existing pieces.

Tips for Success

Removing and reinstalling a Brother sewing machine’s needle threader can be a complicated process. To ensure the best outcome possible, follow these basic tips: read the Owner’s Manual, maintain a clean machine, always pay attention to safety, and purchase a pair of angled tweezers. Additionally, if mechanical issues occur, consult a sewing machine technician.

Moreover, doing trial runs and practicing before attempting a project is beneficial. This allows you to know the machine and become more familiar with the components, making resolution more efficient. Furthermore, it’s best to carry out the task in well-lit areas, as that can aid in locating all of the parts.

Preventive Maintenance

Aside from learning how to take off and put on the threader, preventive maintenance can also help to avoid future difficulties. Some of these management methods include dusting off the parts from time to time, oiling the joints, and making sure that the thread is properly inserted into the spool and the needle.

Additionally, keep track of the machine’s functionalities; if your machine stops performing at its peak, it probably needs to be oiled or maintained. In addition, be mindful of the thread width; while various types can be used with a Brother, each device has its own recommendations or limits as far as thread size goes.

Finally, it is important to add proper waste disposal to the list of preventive maintenance habits. When working with a machine, it is very likely that small scraps and threads accumulate, so they must be thrown away properly.

More Tips and Tricks

Of course, every machine and its individual settings can cause a different experience. As such, here are some other tips and tricks you can use when working with a Brother sewing machine: if the bobbin becomes loose, try tightening it. Additionally, some threaders require additional manipulation; try lightly pushing down on the back of the holder lever if it is stuck. Further, check the winder for any obstructions which could prevent the threader from operating properly.

Moreover, be sure to trim any excess thread from both the bobbin and its holder. Most Brother sewing machines also have an automatic rethreading feature, so in the event of an automatic feed jam, you can use this to quickly resolve the issue. Lastly, when threading the machine with thick thread, use the needle threader twice to increase the thread’s strength.