Sewing machines are a great way to save time and energy when sewing. But, like any machine, they require regular maintenance and occasional repairs. One of the most common problems sewing machine users face is a broken or bent needle. If you find yourself in this situation, don’t worry! Replacing a needle in a sewing machine is a relatively easy task that anyone can do.

To replace a needle in a sewing machine, first remove the presser foot and throat plate. Then, loosen the needle clamp screw and remove the old needle. Insert the new needle into the needle clamp, making sure that the flat side of the needle is facing the back of the machine. Lastly, tighten the needle clamp screw and replace the throat plate and presser foot.

Is it easy to replace sewing machine needle?

If you want to achieve professional results, it is important to change your needle frequently. Waiting for your needle to break or become blunt can lead to subpar results. While it may seem wasteful to change your needle so often, it is worth it in the long run.

The needle clamp screw is the screw that helps us to secure the needle in place. To do this, we can use our l-shaped wrench to tighten or loosen the screw as needed. By doing this, we can ensure that the needle is properly secured and won’t come loose during use.

Can you replace a broken needle on a sewing machine

Most sewing machine manuals come with instructions for replacing the needle, but here are the basics:

1. Loosen the needle set screw

2. Pull the needle downwards and out of the needle bar

3. Insert a new needle

When inserting a needle into a sewing machine, it is important to ensure that the needle is inserted with the flat side facing the back of the machine. This will ensure that the rounded side of the needle is facing forward, which is the correct orientation for sewing.

Do all needles fit all machines?

Sewing machines needles are standardised, which means they are compatible across a range of brands. This includes Janome, Brother, Husqvarna, Elna, and Pfaff. When choosing a needle, be sure to check the compatibility chart to ensure it will work with your machine.

If you are using needle pliers to remove a needle, make sure to hold the needle securely with the pliers. To dislodge the needle, you can either unscrew it or pull it off. Once the needle is dislodged, discard it immediately into a sharps container.

How do you put a needle in an old sewing machine?

There’s a screw up here on the top that needs to be turned to the left in order to loosen it. Once it’s loose, you can easily remove the top and access your needle.

Our screwdriver is a versatile tool that can be used for a variety of tasks. In this instance, we’ll use it to loosen a screw. To do so, simply insert the screwdriver into the head of the screw and turn it to the left.

How do you remove a singer needle plate

To remove the base plate, first lift it up at the back. Then push it backwards. There’s a little lip at the front that you need to lift up in order to completely remove the base plate.

If you have been bitten by an animal, it is important to seek medical attention as soon as possible. If you are able to, firmly but carefully rub your hand over the injection area to locate the needle. If it is found, remove it ensuring that the entire needle is retrieved before seeking veterinary services.

What happens when a sewing machine needle breaks?

If your sewing machine needle breaks, it is important to take the proper steps to fix it. This includes making sure you recover all parts of the needle, as even the tiny broken point can become lodged in the wrong place and cause issues with the machine. Additionally, you may need to adjust the timing on your machine, as a broken needle can thrown it off.

Needle embolism is a rare complication of intravenous drug users. Retained broken needles can lead to local complications, such as infection, but they also have the potential to embolize to heart or lung, and lead to serious complications.

What is the correct way to insert a needle

If you are administering a injection, it is important to hold the syringe in one hand and to pinch up the skin around where you will give the shot with the other hand. The needle should be inserted at a 45- to 90-degree angle. Once the needle is in, you can let go of the skin.

You must make sure that the bobbin is in correctly before you start sewing. If it’s not in correctly, the thread will get tangled and the sewing machine will not work properly.

Does the flat side of the needle go to the front or back?

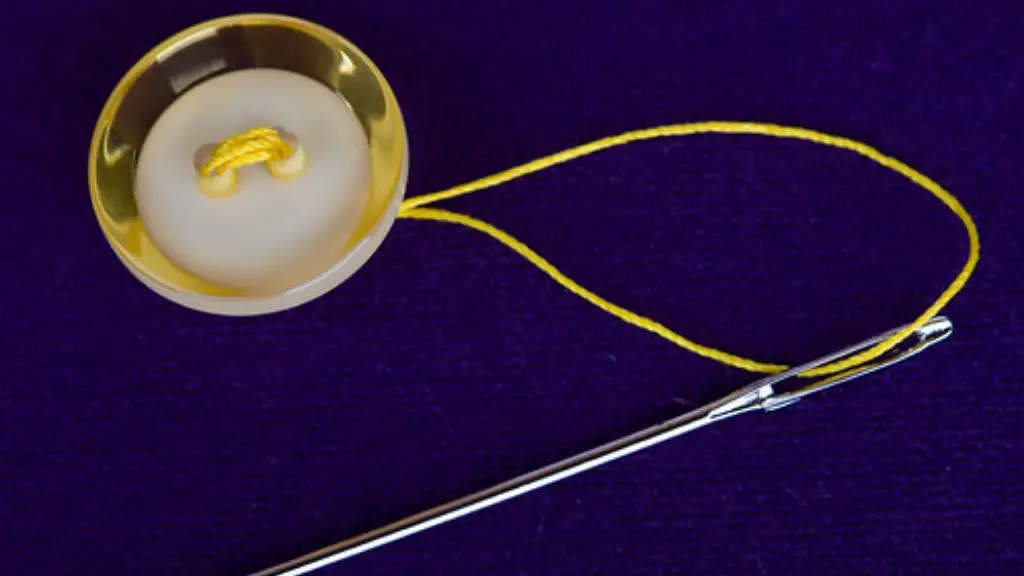

A sewing machine needle is composed of two main parts: the shank and the shaft. The shank is the part that seats into your sewing machine, with the flat side usually facing the back and the rounded side facing the front. Some specialty needles may have a completely round shank. The shaft is the part of the needle that tapers down from the shank. It is where the eye and the point are located. The eye is the small opening near the tip of the shaft through which the thread is fed. The point is the sharp tip of the needle that penetrates the fabric.

This is a good rule of thumb to keep in mind when choosing a needle size for your project. The lighter the fabric, the smaller the needle size you will need. The heavier the fabric, the larger the needle size you will need. The thread you use for your project will also play a role in determining the type of needle you choose.

Warp Up

To replace the needle in a sewing machine, first remove the presser foot and any other attachments. Next, unscrew the needle plate and remove the old needle. Insert the new needle into the machine, making sure that the flat side is facing the back, and then screw the needle plate back on. Finally, reattach the presser foot and any other attachments.

With a few tools and a little bit of know-how, replacing a needle in a sewing machine is a simple process. First, remove the old needle by unscrewing the needle clamp and carefully pulling it out. Next, insert the new needle into the needle clamp and tighten it securely. Be sure to check that the needle is installed correctly before sewing. With a new needle in place, your sewing machine will be ready to tackle any project.