Threading a bobbin in a sewing machine may seem like a daunting task, however with the right knowledge and technique it can be accomplished in minutes. A bobbin is an important component in the functioning of a sewing machine and learning how to thread it correctly is essential for getting the best results from the machine.

The first step in threading a bobbin is to determine what type of machine you have. Different types of machines require different techniques for threading and tensioning the bobbin, so it’s important to familiarise yourself with the one you own. Once you’ve determined the type of machine, you’ll need to locate the bobbin and bobbin holder.

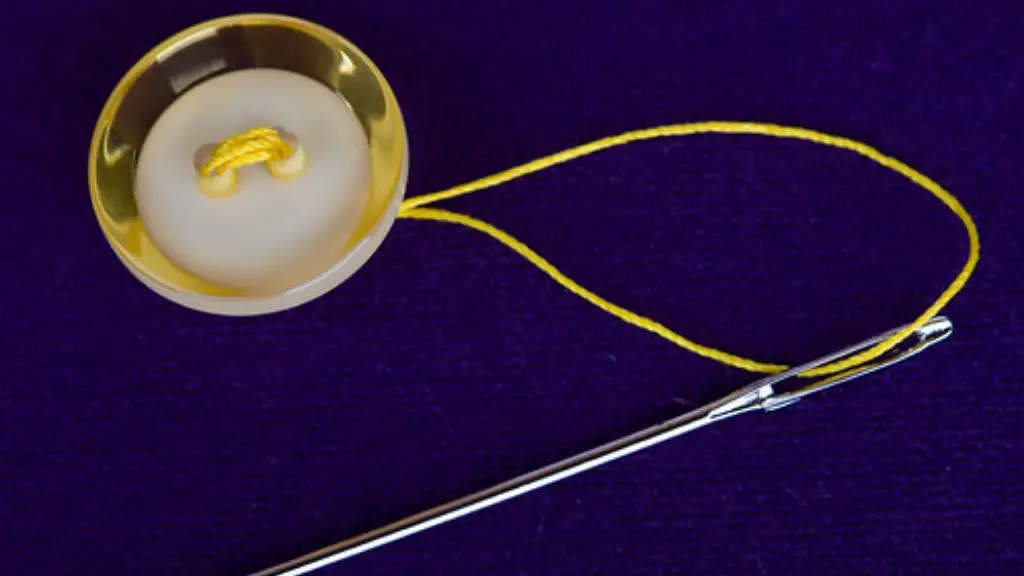

After locating the bobbin and holder, the next step is to place the bobbin in the holder. Make sure that the ribbons or tapes that hold the bobbin in the holder line up with each other. After the bobbin is secure in the holder, place the bobbin into the machine and secure it with the bobbin retaining screw.

The next step is to draw the thread through the bobbin and up to the needle plate. Be sure to thread the needle plate in a clockwise direction, as this will ensure that the bobbin thread is also threaded in a clockwise direction and that the thread will loop properly. Once you have threaded the needle successfully, it is important to check the tension of the bobbin thread.

Tension is essential for the sewing machine to function properly and is the main contributing factor to the overall quality of the stitch. To check the tension, hold the end of the thread from the spool and thread it through the tension disks. If the tension is too tight, loosen the disk until the thread pulls through easily. If the tension is too loose, tighten the disk until the thread pulls through without slack.

Once the tension has been adjusted, it is time to insert the bobbin into the machine. Before inserting the bobbin, be sure to pull the thread taut through the needle plate and the bobbin case. Carefully insert the bobbin into the machine and make sure that the thread is correctly placed in the notch of the bobbin case.

The final step is to engage the bobbin in the machine. This will vary depending on the model of machine, but in general you will need to turn the hand wheel until the needle touches the bobbin thread. Once the bobbin thread has been engaged, you will be ready to start sewing!

Troubleshooting Bobbin Threading Issues

Even with the best care, issues can arise when threading the bobbin in a sewing machine. If the bobbin thread is not looping properly or the stitch is uneven, here are a few common troubleshooting techniques to try.

One of the most common issues is the bobbin winding too tightly or too loosely. If the bobbin is wound too tightly, the stitches won’t form correctly and the thread can break easily. If the bobbin is wound too loosely, the thread can unravel when sewing and create an unattractive, uneven stitch. To fix this problem, make sure to rewind the bobbin with the correct tension and test the thread tension again.

Another common issue is the incorrect thread path. Be sure to thread the thread through the needle plate correctly. If the thread is threaded incorrectly, it can cause the needles and the thread to become tangled and affect the quality of the stitching.

If the problem persists, it may be necessary to make a minor adjustment to the tension discs or the tension screw. When adjusting the tension, it is important to make changes in small increments, testing the stitches after each adjustment.

Important Considerations While Threading Bobbin

When threading a bobbin, there are a few important considerations to keep in mind for optimal sewing results. First, make sure that you are using the correct type of thread for the type of fabric you are working with. If you are using a heavyweight fabric, be sure to select a heavyweight thread. If you are using a lightweight fabric, be sure to select a lightweight thread.

Second, always use a high-quality thread. High-quality threads will last longer, reduce the risk of the thread tangling, and result in a more attractive finished product.

Finally, make sure to use the correct size needle for the thread you are using. Threads come in a variety of sizes, so it is important to select the needle that matches the size of the thread. If the needle is too large for the thread, the stitches will not be as secure and may unravel. If the needle is too small, the thread may break or become distorted.

Care and Maintenance of Bobbin

Not only is it important to learn how to thread a bobbin in a sewing machine, it’s also important to think about how to maintain the bobbin. Over time, the bobbin can become worn and damaged if not handled properly. Here are a few tips for proper bobbin care and maintenance.

First, always make sure to store the bobbin in its original box or packaging. This will protect the bobbin from dust, dirt, and debris that can build up on the metal. Second, make sure to regularly clean and oil the bobbin as needed. Oiling the bobbin helps to keep it in working condition and reduce wear and tear. Finally, be sure to replace the bobbin as needed. Over time, the metal of the bobbin can become worn and will need to be replaced.

Tips for Avoiding Common Mistakes

Threading the bobbin in a sewing machine can be a daunting task, but with a few tips and tricks it’s easy to master. First, make sure to read the manual that came with the machine. This will provide important information about the correct way to thread and use the machine. Second, always thread the needle correctly. Incorrect threading can result in the needle, thread, and bobbin becoming entangled. Third, always use high-quality thread, as this will reduce the risk of tangling and breakage. Finally, make sure to test the thread tension on a scrap piece of fabric and make adjustments as needed.

Conclusion

Threading a bobbin in a sewing machine is a relatively easy process. With the right knowledge, technique, and care, it can be accomplished quickly and without any issues. It is essential for getting the best results from the machine, so it is important to be familiar with the process and to practice regularly. With a bit of practice and patience, threading the bobbin in a sewing machine will become second nature.