Understanding the Nesting Machine

Bird nesting sewing machines are an equipment used in industries for making soft furnishing, home textiles and a variety of fabrics. It has the rotating arbor or needle bar that passes through a set of upper threads which catch the fabric and create a locking stitch. It also uses a pattern wheel that passes through the lower threads which form the loops, thus creating structured and layered designs on the fabric. The tension between the two sets of threads can be adjusted by a regulator.

Hence, the nesting machine requires careful management and handling to ensure that the threading and the tension is right so that the fabrics are not damaged and the patterns and designs are created to perfection. A faulty machine can cause fabrics to bunch up, threads to break and the stitching to become irregular.

How to Identify an Issue with the Nesting Machine

The first step in resolving any issue with the nesting machine is to properly identify it. This can be done by visual inspection or by listening for unusual noises. For example, if the pattern wheel is not catching the fabric or if the arbor or needle bar is moving erratically, then there may be an issue with the nesting machine.

Another way to identify an issue is to look for any loose clamps or nuts that may have become loose due to wear and tear. If any of these have become loose, then it can cause the nesting machine to work inefficiently or not work at all.

One should also check for any thread breaks and ensure that the holes in the fabric are properly spaced. Poorly spaced holes are a sign that the machine may be functioning irregularly and may need maintenance or repairs.

Diagnosing the Problem and Troubleshooting

Once the problem has been identified, it needs to be properly diagnosed. This can be done by opening up the machine and looking for signs of damage or malfunction. One should look at the various components such as the shuttle, the tension regulator and the clamp devices to determine what needs to be repaired or replaced.

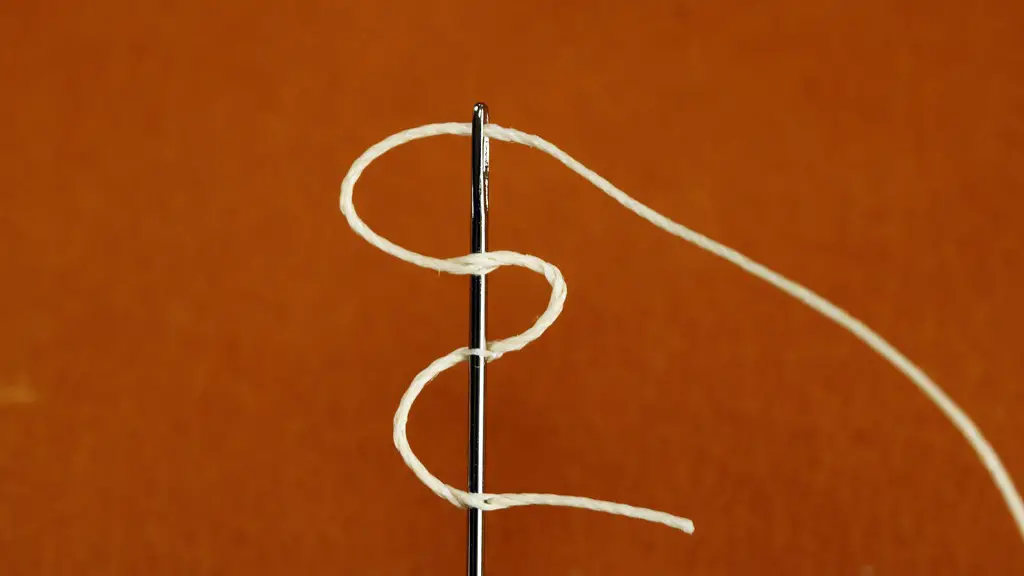

Troubleshooting the machine may involve cleaning it or adjusting settings such as the thread tension or the pressure. If the problem is related to the needle or threading, then rethreading and making sure the threading is correct can help resolve the issue.

If the problem is due to loose or broken parts, then replacing these parts is the best solution. Furthermore, if the machine is making unusual noises then lubricating it may be necessary. Lastly, recalibrating the machine or changing the settings may also be required if it isn’t functioning properly.

Maintenance Tips

Regular maintenance and inspection is important to ensure that the nesting machine is functioning efficiently and is creating excellent quality products. This can be done by properly lubricating the parts, checking the settings and adjusting them if needed, and making sure that all the parts are tightened.

Furthermore, one should also look for any wear and tear that may have occurred due to prolonged use. If wear and tear has occurred, then replacing the parts as soon as possible is important to maintain the overall quality and performance of the machine.

Lastly, it is important to read the manual provided with the nesting machine and consult with a professional if necessary to ensure the safe, efficient and proper functioning of the machine.

Important Safety Measures

When performing maintenance, repairs or adjustments on a nesting machine, it is important to exercise caution. This includes wearing protective gear such as gloves, eye goggles, and face masks. Furthermore, one should make sure that the machine is unplugged before opening it to prevent any electrocution or injury.

It is also important to not force any part of the machine and to install any replacement parts correctly. The manual provided with the machine should be consulted for proper installation instructions. Lastly, the nesting machine should be aligned correctly following any maintenance or repairs.

Summary

Issues with a nesting machine can occur due to wear and tear or improper management. To ensure that this does not affect the efficiency of the machine, one should regularly inspect it and make sure that all the components are in proper working order. Furthermore, regular maintenance should be done to ensure that the nesting machine is performing as intended. Finally, it is also important to exercise caution when performing repairs, adjustments or maintenance on the nesting machine.

Cleaning and Replacing Parts

It is important to keep the nesting machine clean and well maintained to ensure optimal performance. This includes cleaning the machine regularly and replacing any broken or worn out parts. Furthermore, it is important to check the alignment of the stitch wheel and the pattern wheel to make sure that they move in the right direction.

Adjusting the settings of the machine is another important part of keeping the nesting machine running smoothly. This includes adjusting the tension of the threads, the pressure of the wheel, and other settings to make sure that the fabrics are being sewn properly.

Tools for Adjustment and Repair

The nesting machine requires the use of special tools for making adjustments and repairs. These include the hex keys, screwdrivers, wrenches and other tools that are required for opening, adjusting and replacing parts. It is important to use the proper tools to ensure that the parts are installed correctly and that the nesting machine is running properly.

Furthermore, it is also important to use the correct thread for the nesting machine. Thread thickness and type can affect the performance of the machine and hence, one should match the thread type with the nesting machine’s specifications to ensure smooth functioning.

Preventative Measures While Sewing

It is important to take some preventative measures to ensure that the nesting machine is functioning properly while sewing. This includes checking the thread tension regularly and adjusting it as necessary. Furthermore, it is also important to pay attention to the fabric and to identify any areas that may be bunching up or not sewing properly.

It is also important to not overload the machine and to space out the patterns properly. Patterns that are too close together can cause the machine to sew irregularly and can also affect the overall stitch quality. It is also important to change the needle regularly to ensure that the fabrics are being sewn properly.

Finally, it is important to have spare threads and needles to replace any damaged or worn out threads and needles. This can help prevent unnecessary delays and ensure that the stitching is always of the highest quality.