What is a Bobbin on a Sewing Machine?

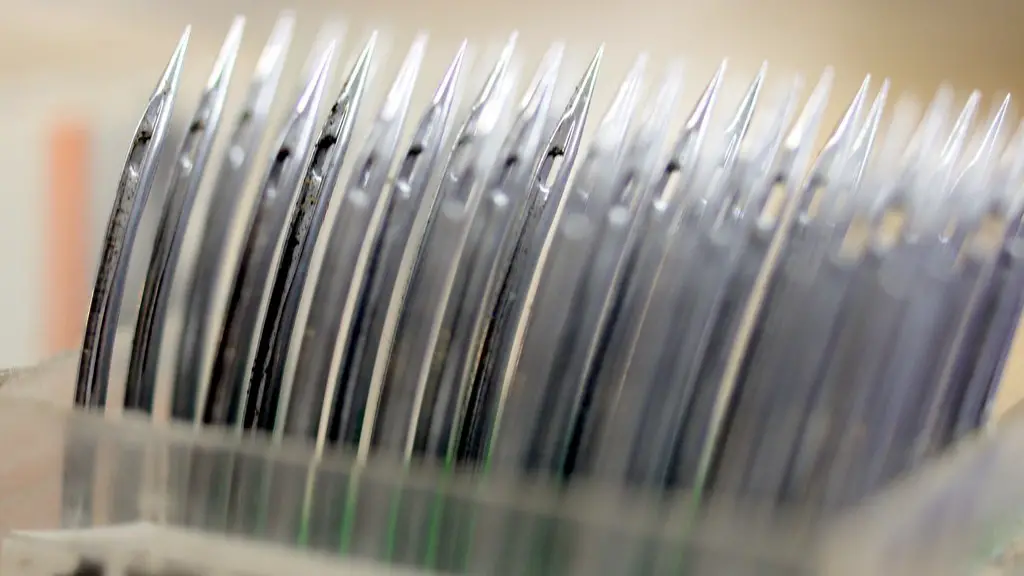

Bobbins are a fundamental element of any sewing machine. Generally made of metal or plastic, they are the little cores that are set below the sewing machine needle, spinning rapidly to assist threading. Without the bobbin, it would be impossible to sew.

Any type of machine needs to be able to thread itself; bobbins are an essential part of this process. On a sewing machine, the bobbin is a tiny spindle, usually constructed from plastic or metal, that is placed beneath the needle. It is this bobbin that is responsible for threading the fabric in a consistent, regular fashion.

Bobbins often come with their own separate spools. The thread is drawn from the spool and is looped onto the bobbin first, before being fed into the needle. It is this loop that is responsible for creating even stitches when sewing.

Bobbins can be inconveniently small and require careful handling. If they become unthreaded while sewing, they need to be rethreaded before use. Depending on the machine, a screw may be required to fasten the bobbin in place. It is important to make sure that the bobbin is securely attached, otherwise it may damage the machine.

In addition to the needle’s thread, the bobbin also provides tension to the fabric. Proper tension requires both the top and bottom threads to be pulled in the same direction at the same time. When this happens, the stitches should look smooth and even with no kinks or loops.

Undoubtedly, the bobbin is a necessary component of the sewing process. Without bobbins, it would be impossible to achieve consistent stitching, and the sewing machine as we know it today would be very different.

Understanding Bobbin Sizes

Bobbins come in a range of different sizes, and the right size needs to be chosen for the specific machine. Generally, the larger the needle size, the larger the bobbin size required.

The most common bobbin size is the Class 15, which is compatible with most domestic machines. However, larger machines require larger bobbins, such as the Class 66 or the Class 125. Widely used on industrial sewing machines, these bobbins come in a variety of shapes and sizes.

If a bobbin is too small for a particular machine, it may not fit in the bobbin case or it may not be able to spin fast enough to provide proper tension. Equally, using a bobbin that is too large for the machine may lead to poor tension, breakage or jamming.

To avoid these issues, it is important to only use the bobbin size that is specified for the particular machine and thread. Most domestic machines come with selector dials that allow the user to adjust the size of the bobbin.

At the same time, it is also important to check that the spool and bobbin are of the same type. Generally, the spool and bobbin should be the same material, the same size and they should be treated with the same type of lubricant.

Reasons for Bobbin Problems

If bobbins are not properly installed, problems can arise. Some of the most common issues include loosening of the thread, breaking of the thread, poor tension and excessive friction.

Usually, improper threading is the culprit. If the bobbins are threaded correctly, these issues should not occur. For example, if the bobbin isn’t threaded correctly, it can cause the needle to catch on the thread and cause it to break.

Similarly, if the bobbin is over-tightened, it can cause the thread to pull too tight, resulting in poor tension and tension problems. If the bobbin is too loose, it can result in gaps in the fabric and may even cause the needle to break.

Incorrect installation is not the only reason for bobbin problems. Over time, bobbins can wear out or become filled with dust, lint and dirt, which can interfere with the threading process. Therefore it is important to keep the bobbin clean and lubricated to prevent issues with tension.

Properly maintained bobbins can be used for a long time without experiencing any problems. Nonetheless, some bobbins may need to be replaced after a certain amount of use.

Tips for Sewing with Bobbins

Using bobbins is a simple process but it is important to get it right. Start by threading the bobbin according to the machine’s manual. Make sure to use the right size bobbin and to thread the bobbin and spool in the same direction.

After threading, it is important to adjust the tension. The tension needs to be tight enough to keep the threads from unwinding but not so tight that it causes problems with the stitch. To adjust the tension, it may be necessary to loosen or tighten the bobbin itself.

It is also important to keep the bobbin and spool clean and lubricated. Lubricating the bobbin can help to reduce tension issues and improves the machine’s overall performance.

Finally, it is important to replace the bobbin when necessary. If the bobbin is worn out, deformed or its thread has unravelled, it is time to replace it. Worn out bobbins can cause tension problems and can also damage the machine.

Benefits of Bobbins

Bobbin–based machines are useful for creating intricate garments and fabric decorations. The most common uses of bobbins include creating quilts, making buttonholes and creating hems. In addition, bobbins can be used to create elaborate decorative patterns, such as lace edges and floral patterns.

Bobbins are also useful for creating garments with multiple layers. With bobbins, it is possible to switch threads quickly and easily, making it a very convenient sewing method. Additionally, most bobbins come pre-threaded, so there is no need to manually thread the bobbin.

In conclusion, bobbins are an essential part of any sewing machine. They provide tension to the fabric and keep the thread in place. Understanding how bobbins work and how to thread them correctly is key to achieving consistent stitches with good tension.

Using Bobbins to Create Professional Finishes

Bobbins enable users to create professional finished garments and fabrics. Intricate embroidery and decorative patterns are possible when using a bobbin. In addition, bobbins can be used to create numerous layers in fabric, making it easy to create a variety of garments.

In terms of quality, bobbins are ideal for creating straight, even stitches. Furthermore, when used correctly, bobbins can help to create tight and professional hems. Overall, bobbins are a great way to achieve professional results in a short amount of time.

However, it is important to make sure that the bobbin is of the right size and tension. Incorrectly threaded bobbins can cause tension issues and may result in poor stitch quality. Therefore, it is important to take the time to thread and adjust the bobbin correctly.

When using bobbins, it is also important to pay attention to specialty bobbins. Specialty bobbins are designed with specific fabrics in mind and may be required to ensure a proper finish. For example, using a metallic bobbin can help to create better stitch patterns with metallic threads.

Advantages of Buying Pre-threaded Bobbins

Buying pre-threaded bobbins can be a great way to save time when sewing. Pre-threaded bobbins come with the thread already wound and are therefore ready to use. The thread is secured in place with a stopper and the user only needs to attach the bobbin to the machine.

Time and effort can be saved using pre-threaded bobbins, as the user does not need to manually thread the bobbin themselves. This is especially useful for time-consuming projects, such as quilting and embroidery, as it can leave more time for creative activities.

However, pre-threaded bobbins are generally made of plastic and may not be compatible with all machines. Additionally, they may not be as durable as metal bobbins, and they may need to be replaced more frequently.

All in all, pre-threaded bobbins are a convenient way to save time and effort when sewing. They can be compatible with a variety of different machines, and they can be useful for more complicated projects. Nevertheless, it is important to choose a durable bobbin that will last.

Factors to Consider When Buying Bobbins

When buying bobbins, it is important to consider a number of factors. Firstly, it is important to choose a bobbin which is compatible with the type and size of the machine. Secondly, consider the type of thread that will be used. Different threads require different tension, and therefore different bobbins.

In addition to this, it is important to consider the type of fabric that will be used. Heavier fabrics require heavier bobbins; otherwise the thread may pull too tight and snap. Moreover, some fabrics require specialty bobbins, such as metallic or stretch bobbins.

Generally, metal bobbins are considered to be more durable than plastic bobbins. Metal bobbins are also less likely to rust, which can be an issue with plastic bobbins. Nevertheless, plastic bobbins are often lighter and easier to thread.

Finally, the price should also be taken into consideration. The cost of bobbins can vary, and it may be worth investing in higher quality bobbins, as they will be more reliable and last longer.

When buying bobbins, it is important to consider the type and size of the machine, the type of thread, the type of fabric, the material of the bobbin. and the price. Choosing the right bobbin can make a huge difference to the quality and the durability of the finished garment.