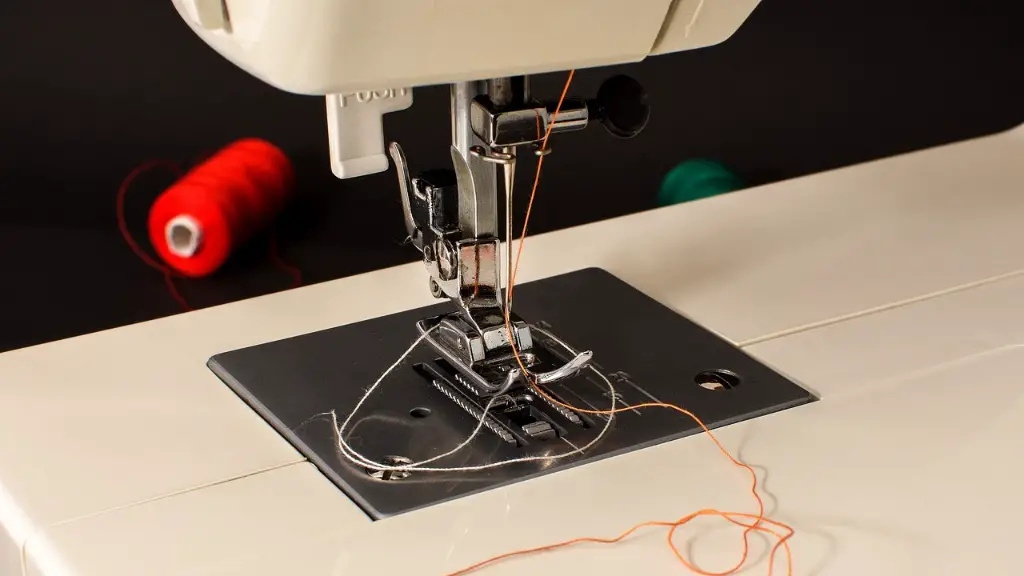

Sewing machines are one of the most important tools in a seamstress’s arsenal, and y they can be pretty finicky beasts. Yes, even the best of them can act up from time to time. So, why do needles break on sewing machine?

Needles break on sewing machines for a variety of reasons. Sometimes it’s because the needle is not compatible with the fabric you’re trying to sew. Other times, it could be that the needle is dull or damaged. And then there are those times when the machine just isn’t properly threaded.

Whatever the reason, it’s always frustrating when a needle breaks in the middle of a sewing project. But don’t worry, we’re here to help. In this article, we’ll walk you through the most common reasons needles break on sewing machines and what you can do to prevent it from happening again.

The most common reason that needles break on sewing machines is due to hitting a pin or other object while sewing. Needles can also break if they are installed incorrectly, or if the machine is not properly maintained.

What is the most common cause of needle thread breaks?

If your needle is not inserted properly, your threads can break. Make sure the eye of the needle is facing the front, and that the scarf (indent) of the needle is facing the back. Burrs in the needle may also cause the thread to shred. It’s also important to check up on your needles from time to time.

If your sewing machine needle gets damaged or bent, it can hit your feed dogs, throat plate, or bobbin case and break. To avoid bending your needle, try to slow down while you’re sewing or use a sharper needle.

What are some things that can cause a needle to break

There are a few reasons why a sewing machine needle may break. The most common reason is that the thread catches on the spool or wraps around the spool cap. This can cause the needle to break or bend. Other reasons include the thread wrapping itself around a thread guide more than once, the fabric being “helped” through the machine, or the sewing machine needle being too small. If the needle is not inserted all the way, this can also cause it to break. Finally, the needle screw may not be tight enough, causing the needle to come loose and break.

There could be several reasons why the needle keeps breaking:

– Make sure the needle is correctly inserted with the flat side facing the back and pushed up into the machine as far as possible

– The needle could have been damaged or bent

– Make sure the fabric is not pulled excessively when sewing

How common is needle breakage?

Needle breakage during an infiltration is uncommon, but can occur if the needle used is of inferior quality. If only one needle breakage is found during an infiltration, it is not typically a cause for concern.

The dial settings on a sewing machine typically range from 0 to 9, with 45 being the “default” position for most straight-stitch sewing. This setting should be suitable for most fabrics. However, it’s always a good idea to test the stitch on a scrap piece of fabric before sewing on your project, just to be sure.

What to do if a needle breaks off?

If you find a needle in your pet’s injection area, carefully remove it and bring it to your vet. It is important to make sure that the entire needle is retrieved.

Sewing needles typically last between 6 and 10 hours before they need to be replaced. This varies depending on the thickness of the fabric being used. It is important to change needles often to avoid problems such as tugs in the fabric, uneven stitches, and other common sewing headaches.

How do you fix a broken needle on a sewing machine

If you need to change the needle on your sewing machine, follow these steps:

1. Loosen the needle set screw.

2. Pull the needle downwards and out of the needle bar.

3. Insert a new needle. If using an industrial sewing machine, turn the needle so the scarf is on the same side as the hook assembly on the machine.

4. Tighten the needle set screw.

This is an idiom that means the song was very loud.

What is the biggest cause of needle stick injury?

Needlestick injuries are a serious problem in the healthcare industry. They can be caused by a number of factors, but the most common ones are syringe needle heads and angiocatheter. Providing safe medical equipment should be a priority in order to prevent these injuries from happening.

If you have a wound that is taking longer than 2 weeks to heal, you should watch for signs of infection. Symptoms might include swelling, redness, pain, or pus coming from the wound. If you notice any of these signs, you should call the doctor.

Should needles be bent or broken

According to the OSHA Bloodborne Pathogens Standard, needles must not be bent, sheared, broken, recapped, removed from disposable syringes, or otherwise manipulated by hand before disposal when used with infectious or potentially infectious materials. This is to prevent the spread of bloodborne pathogens.

The correct bobbin tension will allow the thread to unwind easily and the bobbin case to drop a few inches. If the thread unwinds without resistance and the bobbin case slips to the floor, your bobbin tension is too loose. If the bobbin case doesn’t budge, your bobbin tension is too tight.

What number should bobbin tension be?

Proper bobbin tension is essential to good embroidery. If tension is too tight, unwanted bobbin thread may begin to show on top of your garment and you may begin to experience frequent thread breaks which wastes time and money. Bobbin tensions should be 18 to 22 grams (up to 25 grams when embroidering caps).

The most common stitch lengths used are 8-10 stitches per inch (25-30 mm) for standard stitch length, 4-5 stitches per 50-70 mm for basting, and 12-8 stitches per 15-20 mm for stay-stitching. The best stitch length to use depends on the stability of the fabric, the weight of the thread, the type of sewi

The most common stitch lengths used are 8-10 stitches per inch (25-30 mm) for standard stitch length, 4-5 stitches per 50-70 mm for basting, and 12-8 stitches per 15-20 mm for stay-stitching. The best stitch length to use depends on the stability of the fabric, the weight of the thread, the type of sewing machine needle used, and the desired look of the finished project.

Warp Up

Needles break on sewing machines for a variety of reasons. The most common reason is that the needle is not properly inserted into the needle bar. If the needle is not properly seated, it will rub against the side of the needle bar and eventually break. Other causes of needle breakage include using the wrong type of needle for the fabric being sewn, sewing too fast, or sewing over pins.

Needles break for a variety of reasons, the most common being incorrect installation, Foreign Objects inside the Machine, Believe it or not,Hand Fatigue, and lastly, Manufacturers Fault. While there are many possible explanations, the most important thing is to take care of your machine and make sure you’re using the correct needle for your project.