Whether you’re an experienced sewist or just learning the basics of sewing, you’re likely to appreciate the value of taking good care of your tools. When it comes to sewing machines, maintenance is key in order to extend the longevity of the appliance. Oiling is one of the regular maintenance tasks that you should do for your sewing machine.

It’s recommended to oil your sewing machine every 6 months or at least once a year. However, anytime you notice squeaking, a lack of power and torque, or if your machine starts running hotter than normal, it’s likely time for some tuning up and oiling.

In general, many sewing machine manufacturers recommend that you oil a sewing machine every time you change the needle. Additionally, for a high-volume or commercial-grade sewing machine, you may need to oil it on a monthly basis

Oiling your sewing machine is a simple, straightforward process that can be done at home. Before you start, however, always make sure to disconnect your machine from power source, then remove any fabric or thread that may be in the machine. It’s also important to refer to your machine’s manual to make sure that you’re using an appropriate sewing machine oil.

Most sewing machine oils will do an effective job at lubricating your machine’s moving parts. To apply the oil, take a drop on your fingertip and carefully put a thin layer of oil inside the bobbin case, around the tension discs, on the sewing needle bar, the needle bar bushing, the rotary hook, and any other visible moving parts.

To go even further, you can use a small paintbrush to gently dab little drops of oil onto tight or hard-to-reach places. It’s important to remember that sewing machine oil shouldn’t come into contact with any electrical components as it may cause a fault. You should also take care to not overfill your machine as it could affect its performance.

Additionally, it’s important to keep a few other things in mind when maintaining your sewing machine with oil. For instance, never apply oil while the sewing machine is running. Since there are few oils that are safe to use with the lubricating system of computer-controlled machines, always check the appropriate manual before getting started. Finally, after you finish oiling, run your sewing machine for 2-3 minutes to ensure everything is lubricated.

Different Sewing Machine Oils

Before oiling your sewing machine, it’s important to consider which type of oil to use. Slightly different types of oils are available on the market, including specialized sewing machine oil and multi-purpose lubricant.

Sewing machine oil is formulated with a light viscosity that makes it effective for quickly delivering lubrication inside small, delicate machine parts. It also resists gumming up, so you won’t have to worry about having to clean your machine more often. On the other hand, multi-purpose lubric with a higher viscosity may not provide the same degree of protection.

In any case, make sure to test a small portion of the oil before using it on your entire machine. Also, never use motor oil, WD-40, or 3-in-1 oil as a substitute for a high-grade sewing machine oil.

Machine Cleaning

It’s also good practice to clean your sewing machine at least once a year or, if you’re using the appliance a lot, every six months. Proper cleaning of your machine is essential for its performance and for a better-sewn project, as it will remove any dust, debris, and build up of lint around the bobbin and feed dog.

Like oiling, machine cleaning is a simple process. Begin by removing the needle, bobbin, and presser feet, then wipe the lint off the feed dogs with a lint brush. Make sure to collect lint and dust from inside the bobbin case and use a damp cloth to gently clean the machine’s exterior before moving onto the oiling process.

When wiping the machine, avoid water superheat and never use abrasive cleaning products. All you’ll typically need is a lint brush, a soft cloth, and a little bit of soapy water for a thorough clean.

Upkeeping Your Sewing Machine

Aside from oiling and cleaning your sewing machine, you’ll also need to regularly check for other common issues that can occur. Over time, the screws may loosen, so check them for tightness and ensure that the machine’s knives and needles are in proper working order.

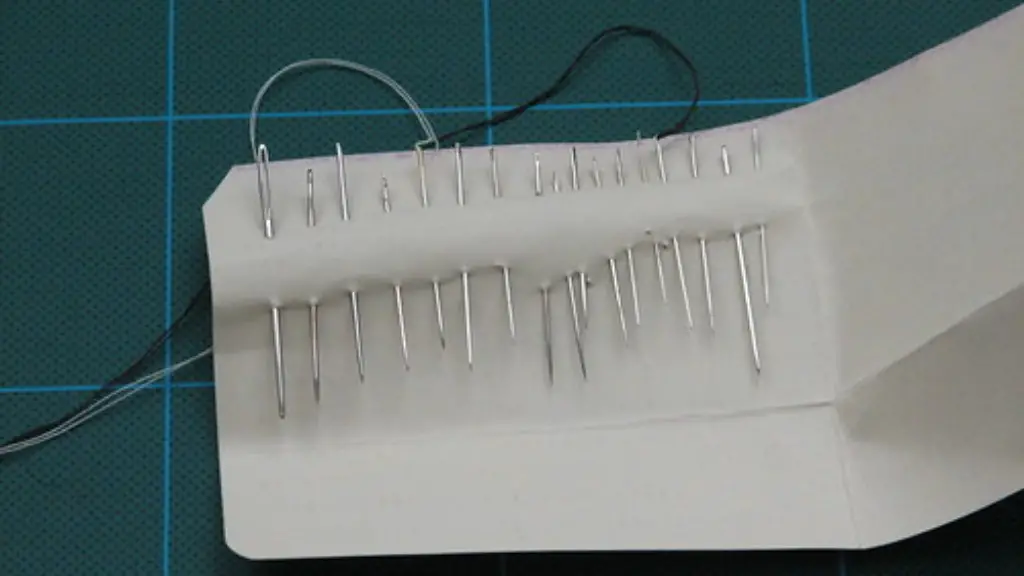

Periodic check-ups are especially critical after using your machine to sew heavy materials. It’s also recommended to always remove the fabric from the machine and adjust the tension before changing the needle.

Lastly, always make sure to use the right type and size of needle for the fabric. Needles can get bent, worn, or deformed as well, which could cause skipped stitches, puckered fabric, or even breaks in the thread.

Keeping Your Machine Running

At the end of the day, a well-maintained sewing machine will give the best performance. Taking care of the machine is the most important step for anyone who wants to make sure their projects look great. Making sure to oil your machine regularly and after each use, cleaning it consistently, and adjusting the tension are essential for ensuring a smooth sewing experience.

It’s also a good idea to keep a record of when you perform cleaning and oil maintenance tasks. This will help you to remember when it’s time to move on to the next task and make sure you do the necessary, scheduled check-ups.

Sewing Machine Brands and Models

Not all sewing machines are the same, so you should always refer to your machine’s manual before oiling. Different brands may require more frequent oiling, fewer drops, or a different type of oil—for instance, while Brother sewing machines generally recommend oiling every 10 hours of use, Janome’s machines may require less frequent oiling. Make sure to check the manual to determine the specific requirements.

It’s also crucial to make sure that the oil you purchase is compatible with the type of sewing machine you have. This means you need to select the right oil for the right type of machine. Since some models are more complex than others, always double-check the manual for specific oil recommendations for your machine.

Tips for Applying Sewing Machine Oil

It can be easy to over-oil a sewing machine, so it’s important to take a few precautions. Make sure to apply the oil carefully and in small amounts as too much oil can cause the machine parts to malfunction or even short out the system.

Additionally, it’s recommended to pour the oil onto a soft cloth, like a microfiber towel, instead of directly onto the machine parts. This will help to avoid over-oiling and ensure that the oil is evenly distributed.

When cleaning the sewing machine, always remember to only use water- based cleaning agents and to never use cleaning products that contain petroleum or petroleum distillates. These could leave a sticky residues or damage the machine, so it’s best to avoid them altogether.

Conclusion

In conclusion, it’s essential for sewists and quilters to oil their sewing machine periodically to ensure it is working properly. Most machines require oiling every six months or so, although this amount may vary according to the machine and the amount of use. Additionally, it’s important to use only sewing machine oil and to take safety precautions when oiling, such as never applying the oil with the machine on and pouring the oil onto cloth instead of applying it directly.