It is common to encounter issues with a Singer sewing machine from time to time, including problems with the timing. The timing of your machine is not only important for its functionality but also for cogency in stitching. The fact is that the timing can easily get disrupted and must be carefully corrected to get the job done well. Most people may be unaware of this fact but fixing the timing on a Singer sewing machine is not complicated.

The timing on a Singer sewing machine can be fixed by simply adjusting the upper tension. This is one of the main settings on the machine and must be adjusted to ensure the machine’s timing is as accurate as possible. Start off by loosening the upper tension scheduler. Then, slowly begin increasing tension with the help of a tension adjuster. Make sure to slowly increase the tension to ensure that the threading tension is set correctly.

It is also important to remember that some machines require a full reset to effectively re-time the machine. A full reset may take some time and should only be done if all previous settings have failed. With a professional approach from a qualified technical engineer, a reset of the machine should not cause any damage.

In addition to resetting the machine and adjusting the tension, all of the threading should be inspected for wear and tear. If any part of the threading appears to have come loose, it should be rethreaded correctly and tested to see if it has been done correctly. It is also important to check for any oiling or lubrication. Some Singer sewing machine models require regular oiling to keep them running smoothly.

Given the variety of models that Singer produces, it is always wise to consult the manual or an expert to determine how best to reset and re-time the machine. The manual contains clear instructions on how to do this safely and accurately; however, if the user is unfamiliar with the machine, it may be best to seek out help and guidance from an expert.

Checking the Drive Gear and Retainer Nuts

Another important step in fixing the timing on a Singer sewing machine is to check the drive gear and retainer nuts. Ideally, all gears should run at the same speed to keep the machine running smoothly and in time. If any retainer nuts have come loose, they must be checked and tightened and all of the gears must be inspected for wear and tear.

Next, it is necessary to check the belt that runs between the drive gear and the motor. The tension of the belt must be steady and the belt must be in good condition – if not, it must be replaced. Finally, check the type of needle being used. If it is the wrong type or size, it can also cause issues with the timing of the machine.

Testing the timing after repair

Once all repairs have been completed, it is important to fully test the Singer sewing machine to see if it is in working order. It is important to remove any fabrics or threads from the bed of the machine before testing. Next, make sure to test the settings. Adjust the settings so that the machine is running at the right speed and at the right timing.

Also, make sure to check the bobbin threading. Thread the bobbin correctly and pull it out to make sure it has been threaded correctly. Finally, test the machine stitching by actually using the machine to sew together a piece of fabric. If the stitch appears even and consistent, the timing is likely correct.

Preventative maintenance

Preventative maintenance is the best way to take care of your Singer sewing machine and make sure the timing is always correct. Regularly oiling and cleaning the machine is essential in keeping it running smoothly and avoiding any issues with the timing. It is also a good idea to try and limit any abrupt movements as they can easily cause disruption to the timing.

Following these steps can also help to ensure that your Singer sewing machine runs in time, with consistent and accurate stitching. Inspect all the parts of your machine regularly and most of all, make sure that the tension is set properly before and after any major threading job.

Threading and Threads

Before getting started, it is important to verify that the threading and threads used on the machine are all in good condition. Threads that are too old will cause the thread to shred and this can cause timing issues. It is also important that the correct thread is used for the particular job being done. The wrong size thread can affect the timing of the machine, so be sure to use the correct thread for the job.

Some models of Singer sewing machines also use different machines for threading. Be sure to use the right machine for the particular thread you are using so that the thread is molded to the specifications of your Singer sewing machine. This will ensure that it runs smoothly and in time.

Storing the Machine properly

As with all machines, it is important to store the Singer sewing machine properly when not in use. If the machine is not stored properly, it can easily rust and this may cause timing issues. In order to avoid this, make sure to always dust the machine and oil the components regularly. It is also important to store the machine in a cool and dry place to prevent moisture damage.

As you can see, fixing the timing on a Singer sewing machine is not overly complicated. However, it is important to approach the job in a professional manner. This means understanding the machine, taking all the necessary precautions, and remembering to regularly clean and oil the machine.

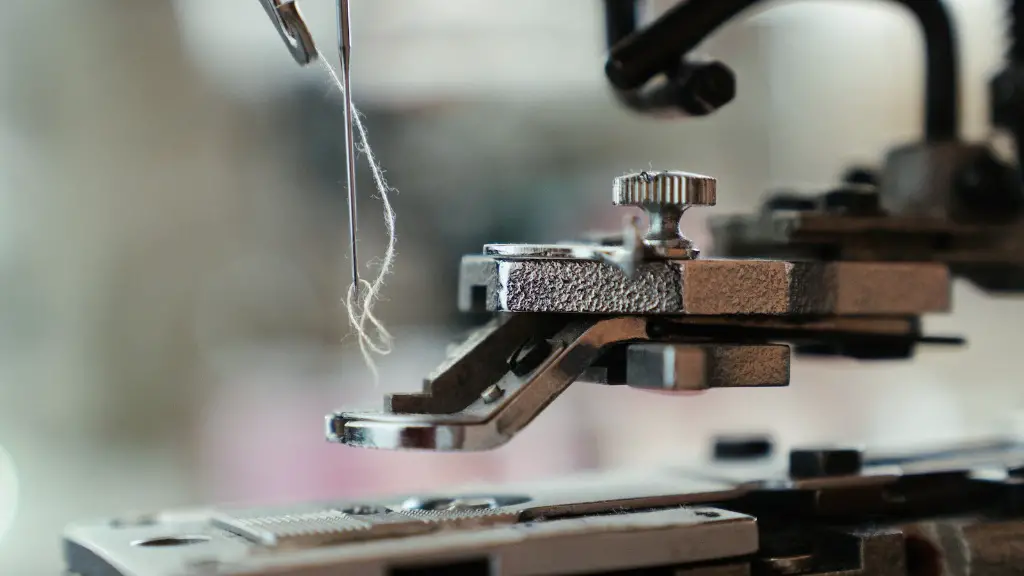

Calibrating the Hook and Needle Settings

Once all of the above steps have been checked, the next step to fixing the timing on a Singer sewing machine is to calibrate the hook and needle settings. This is perhaps the most important step in the process. If the gap between the hook and the needle is too small or too big, the machine’s timing will be off. Therefore, it is important to adjust the tension dials so that the gap between the hook and the needle is set correctly.

Furthermore, it is also important to make sure that the needle is properly guided when stitching. If the needle is not moving in a consistent and regular pattern, its timing will likely be off. To fix this, the needle must be re-calibrated and the tensions must be adjusted.

Finally, if any other parts of the machine have been replaced, it is also important to make sure that all the settings are in line with the original settings. If these settings have been changed, it can easily cause the timing to become off and it must be reset accordingly.

Switching to a Different Model

Sometimes the issue with the timing of a Singer sewing machine may be due to the model itself. Some machines may be outdated and unable to keep up with the current trends. When this is the case, it may be necessary to switch to a different model. When picking out a new model, it is important to ensure that the timing is adjustable and that the machine has all the necessary features to keep it running in time.

In summary, fixing the timing on a Singer sewing machine is not overly complicated. However, it does require a bit of knowledge and patience. Start by adjusting the upper tension, testing the drive gear, checking the type of needle, calibrating the hook and needle settings, and performing regular maintenance. If a full reset is necessary, consult a professional. Of course, if the issue is related to the model itself, a switch to a different model may be necessary.