Sewing machines are great tools that require skill, precision, and knowledge to master. Knowing how to use a needle properly, in industrial sewing machines in particular, is essential for any professional. With the right technique and practice, it’s possible to become an expert and get the perfect stitch every time.

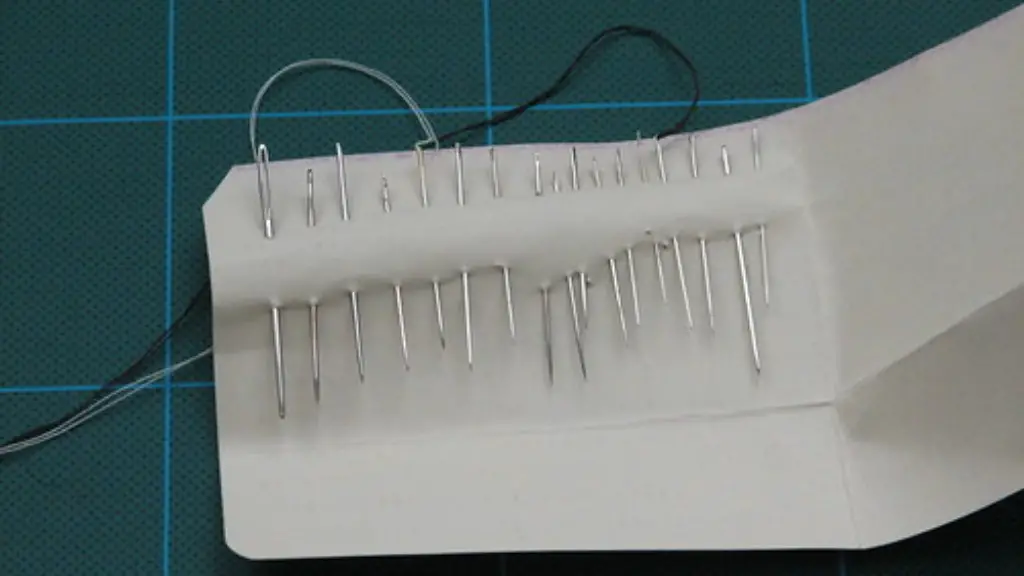

To get started, the most important part of inserting a needle in a industrial sewing machine is to make sure that it is the right type and size for the project. There are many different types of needles that can be used depending on fabric, thread and the application. For example, a smaller needle is more suitable for light fabrics, while a larger one is needed when working with thicker materials.

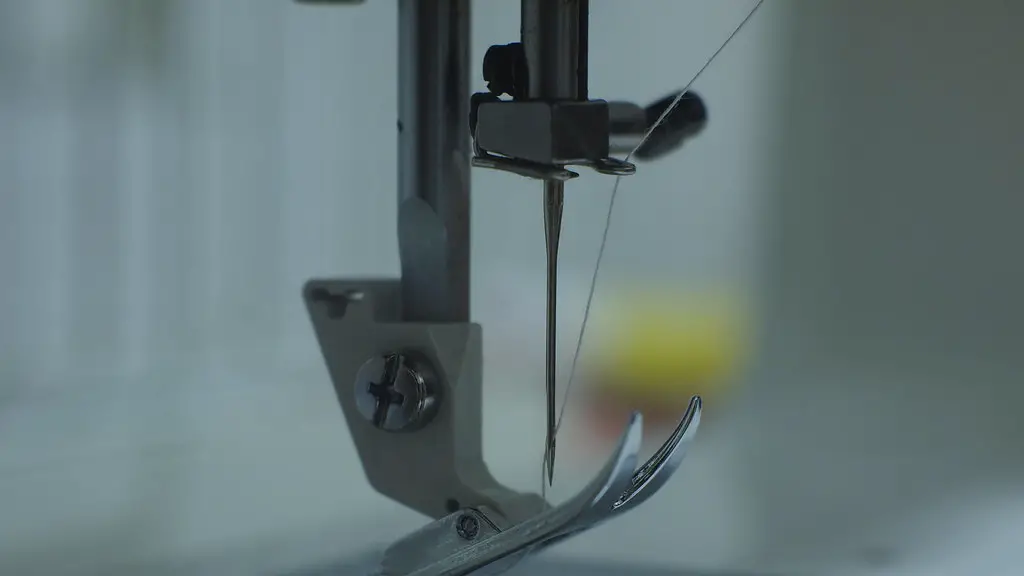

Once the appropriate needle is chosen, the next step is to properly place it. First, the needle must be lined up straight with the throat plate, which is the flat surface of the machine. This is done to make sure that the needle doesn’t damage the material during sewing. Secondly, the flat part of the needle should be facing left when inserted so that the stitching appears properly. Additionally, make sure the needle is properly seated in the needle-cutting bay.

Thirdly, the needle must be securely fastened with the needle clamps. This is done by rotating the hand-wheel or motor of the machine and pushing the needle up into the throat plate. The needle clamps should then be tightened with a screwdriver. Be careful not to over-tighten, as this can damage the needle.

Fourthly, when attaching the needle to the machine, the bobbin tension must be checked. For this, use the bobbin tension gauge. When the gauge’s needle points to the red guide line on the dial, it indicates that the bobbin is properly tensioned; if it is too far away, it means that the bobbin is incorrectly tensioned and needs to be adjusted before sewing.

Finally, when everything is correctly aligned and tensioned, the needle can be tested by pressing the “hand wheel” or motor switch. The needle should rise and fall without any difficulty and without any vibration. If the needle is inserted correctly, it will move smoothly. If it vibrates or causes noise, the needle must be re-inserted.

Threading the Bobbin and Needle

Once the needle is correctly inserted and tensioned, the next step is to thread the bobbin and needle. To do this, the bobbin must be attached to the bobbin-case holder, which is located beneath the needle plate of the machine. The thread should be placed in the needle-threading hole, which is found just above the needle plate. It is important to tightly wrap the thread around the part of the needle that is closest to the thread-guide.

Once the thread is pulled through the thread-guide, it should then be threaded through the eye of the needle. A loop should be made on top of the needle which will help to secure the thread. Lastly, the thread should be drawn up through the needle plate towards the hand wheel and the machine is ready for sewing.

Regular Maintenance and Cleaning

Regular maintenance and cleaning of industrial sewing machines is essential in order to get the best results. A regular cleaning can help to prolong the life of needles and other parts, as well as improve their performance. Disassemble and clean the parts regularly, and make sure that any thread remains is completely removed.

It is also important to check that the needle is still tight, and that it is properly lubricated. Keep an eye on the pulleys and other moving parts to make sure that there are no frayed threads or loose screws. In addition, make sure to inspect needles regularly for signs of wear and tear, and replace them if necessary.

Tension Adjustment and Troubleshooting

The tension of a industrial sewing machine is a key factor for achieving the best results. If the tension is too loose, the stitches may be looser or pucker. On the other hand, if the tension is too tight, it can lead to thread breakage and poor fabric manipulation. To adjust the tension, use the appropriate tensioning device and adjust it slowly until the desired tension is achieved.

If there are problems while sewing, read the machine’s user manual and check the tension, needle and thread. Adjusting the tension is the most common way to troubleshoot a sewing machine. If this does not solve the issue, consult a professional.

When to Replace a Needle

Replacing a needle can be tricky. Not only is it important to know when to replace the needle, but also to make sure that the right type of needle is used for the project. Generally, the needle should be replaced when it shows signs of wear and tear or if its tip is blunt. It’s also important to remember that a needle should never be reused.

Apart from the obvious signs of wear and tear, other indicators of needing a new needle may include skipped stitches, broken threads and uneven stitches. If any of these problems arise, it’s best to replace the needle.

Practice and Patience

Mastering the technique of inserting a needle in a industrial sewing machine requires practice, patience and attention to detail. By following the steps outlined above and consistently practicing the process, it’s possible to become an expert. With the right tools and techniques, it’s possible to achieve perfect stitching results every time.

Other Accessories Required

When working on industrial sewing machines, it’s important to have the right accessories. This includes thread clippers, threaded bobbin winder, fabric scissors and thread stand. Additionally, crease-resistant marking pencils and tailoring chalk can also be helpful. In addition, a cutter blade sharpener and a needle threader can make threading the needle and adjusting the tension much easier.

The Mechanism of the Stitch Formation

When the needle moves up and down to stitch the fabric, it creates a loop of thread around the needle. This loop passes through the fabric when the needle moves down and is locked in place when the needle moves up. The thread from the needle creates the top thread of the stitch, while the thread from the bobbin creates a loop underneath the fabric, forming the bottom thread of the stitch.

The thread tension and speed must be in balance to create the perfectly balanced stitch. Too much tension will cause the thread to be too tight and the stitches to be too close together; too little tension will cause the stitches to be loose and messy. Finally, the needle’s size and shape must be suited to the project, as this will determine the size, type and shape of the stitch.

Types of Stitches Used in Industrial Sewing Machines

The type of stitch used in industrial sewing machines is usually determined by the type of fabric, type of thread and the application. Some popular stitch types include straight stitch, zigzag stitch, quilting stitch and bartack stitch. The straight stitch is the most common and versatile stitch, whereas the zigzag stitch is mostly used for decorative purposes. Finally, the bartack stitch is used to reinforce the fabric and add durability and strength to the seams.

The quilting stitch on the other hand, is used to sew together multiple layers of fabric. This type of stitch requires a specially designed needle and foot to create an even, precise and durable stitch. Finally, when using industrial sewing machines to create patterns, a three-step zigzag stitch can be used to achieve the desired effect.

Conclusion

Inserting a needle in a industrial sewing machine is a precise and intricate process that requires skill and knowledge. With the right techniques and practice, it’s possible to become an expert. Knowing how to select an appropriate needle, properly placing and tightening it, and threading it correctly are key steps for successful stitching. Regular maintenance and cleaning, as well as using the right accessories, will also help to get the best stitching results.