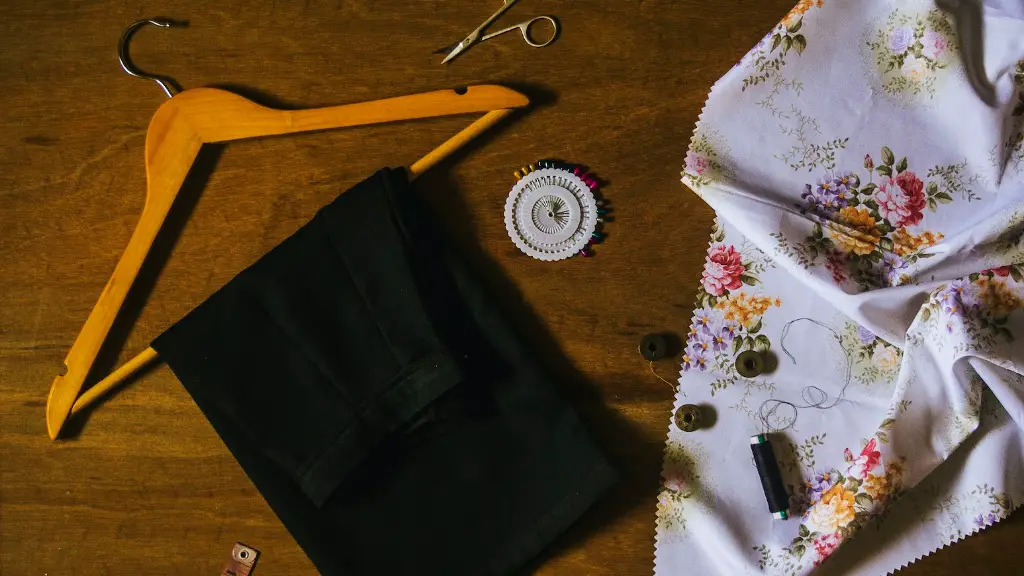

The first step in loading the bottom of a sewing machine is to make sure you have the necessary supplies. The necessary supplies include fabric, thread, a needle, and a machine bobbin. If you have all these items, you can begin to load the sewing machine. The steps to load the bottom of a machine are simple, but must be followed carefully.

Firstly, make sure that the needle is inserted correctly into the machine. You will want to double check that the needle is in the correct spot and that the thread is threaded properly through the needle. Once the needle is correctly placed, it is time to thread the machine bobbin. To do this, you will need to locate the bobbin winding spindle. The bobbin winding spindle allows you to wind thread onto the bobbin.

After you have found the bobbin winding spindle, you will need to find the thread guide. The thread guide is a small slot that runs along the top edge of the bobbin. Once you have located the thread guide, you will need to drop the bobbin itself into the bobbin case. This can be done quite easily by pressing the bobbin case into the bobbin winding spindle.

Next, you will need to thread the machine bobbin correctly. This is where the thread guide comes in. Once you have located the thread guide, you can thread the bobbin by inserting the thread into the slot and wrapping the thread around the bobbin. Once you have threaded the bobbin correctly, the thread will then evenly be wound around the bobbin case.

Once the bobbin is correctly threaded, you will then need to place the bobbin case into the machine. This is done by inserting the bobbin case into the machine until it is secure. You will then need to place the bobbin case onto the needle plate. Once the bobbin case is in place, you can then begin to sew.

To ensure your sewing is accurate, you will need to ensure that the thread is properly tensioned. To do this, you will need to adjust the stitch tension dial. This is done by turning the stitch tension dial until you achieve the desired amount of tension. Once the thread is tensioned correctly, you can sew away.

In conclusion, loading the bottom of a sewing machine is a relatively straightforward process. It is important to ensure that you have all the necessary supplies and that you thread the bobbin correctly. Once the bobbin is correctly tensioned, you can begin to sew.

Bobbin Storage

In addition to loading the machine bobbin correctly, it is also important to consider the storage of the bobbins. When considering storage, there are several options available.

Firstly, the bobbins can be stored in a cotton-lined box or drawer. This allows for easy access to the bobbins when they are needed. Additionally, the bobbins can also be stored using bobbins boxes and thread organizers. These boxes and organizers allow for easy access and storage of the bobbins and thread.

Furthermore, there are also thread stands and spool holders that can be used to store the bobbins. These stands and holders help to keep the bobbins neat, organized and secure. Additionally, the stands and holders help to prevent the bobbins from becoming tangled and damaged.

The bobbins can also be stored in plastic bags and in pincushions. The bags and pincushions allow for easy access and storage of the bobbins. However, it is important to make sure that the bobbins are placed in an airtight container or bag when not in use to prevent them from becoming dust or dirt.

Bobbin Type

When it comes to loading the bottom of a sewing machine, it is also important to consider the type of bobbin that is being used. Different types of bobbins require different types of loading.

For instance, there are standard bobbins which need to be manually loaded. These bobbins can simply be dropped into the bobbin case. Then, the bobbin must be securely attached to the needle plate. After that, the bobbin should be firmly tightened with the bobbin winding spindle.

There are also drop-in bobbins which require a specific type of loading. These bobbins have a slit which allows for the thread to be placed into the bobbin. Then, the bobbin is dropped into the bobbin case. Then, the bobbin will be secured by the bobbin winding spindle.

In addition, there are also magnetic bobbins. These bobbins are designed with a magnet that allows for the bobbin to be dropped into the bobbin case without the use of the bobbin winding spindle. Once the bobbin is dropped into the bobbin case, the magnet will secure the bobbin in place.

Bobbin Winding

In addition to loading the bobbin correctly, you will need to make sure that the bobbin is wound correctly. This can be done by adjusting the bobbin winding spindle. To make sure the bobbin is wound correctly, you will need to adjust the tension of the thread that is being wound around the bobbin. If the thread is too tight, it will cause the bobbin to be wound too tightly. If the thread is too loose, the bobbin will be wound too loosely. Once the bobbin is wound correctly, it can then be securely attached to the needle plate.

To ensure that the bobbin is wound correctly, you will need to check the thread tension. To do this, your will need to press the thread tension disc. This will allow the bobbin to get the correct amount of tension. Once the thread tension is correct, you can begin to sew.

In addition to this, you will need to make sure the bobbin is wound evenly. This can be done by checking the bobbin winder periodically. If the bobbin winder is not winding the bobbin evenly, you will need to adjust the tension knob on the bobbin winding spindle to increase or decrease the tension of the thread winding on the bobbin.

Cleaning the Bobbin Area

When it comes to loading the bottom of a sewing machine, it is also important to consider the cleanliness of the bobbin area. To keep the bobbin area clean, you will need to regularly clean it. This can be done with a soft brush or damp cloth.

In addition to this, it is important to not use any harsh cleaning chemicals on the bobbin area. This can damage the machine and harm the user. Also, it is important to not use any hard objects to clean the bobbin area as this can scratch or damage the bobbin case or other parts of the machine. Instead, it is best to use only soft brushes, rags or damp cloths.

Furthermore, it is important to periodically check the bobbin case for any signs of wear or damage. This can be done by carefully inspecting the bobbin case for any broken or bent parts. If any parts of the bobbin case are broken or bent, you may need to replace the entire bobbin case. Additionally, it is important to regularly oil the bobbin area to ensure that it is functioning properly.

Conclusion

In conclusion, loading the bottom of a sewing machine is an important aspect of sewing. It is important to make sure that you have all the necessary supplies and that you thread the bobbin correctly. Additionally, it is important to consider the type of bobbin and the bobbin winding when loading the bottom of the machine. Finally, it is important to make sure the bobbin area is kept clean and oiled to ensure that it is working properly.