Gathering Parts and Preparing the Machine

Preparing your sewing machine for a bobbin threading is a critical, but straightforward process. You will want to start by gathering all the parts of your bobbin, such as threading hooks, the bobbin holder, and the bobbin thread. Once you have all of these parts, it is important to make sure that each part is properly lubricated and clean. If the parts are not properly maintained, then it can cause tension problems and possible breakage. Once you are sure that all the parts are clean and properly lubricated, you can proceed to threading your sewing machine.

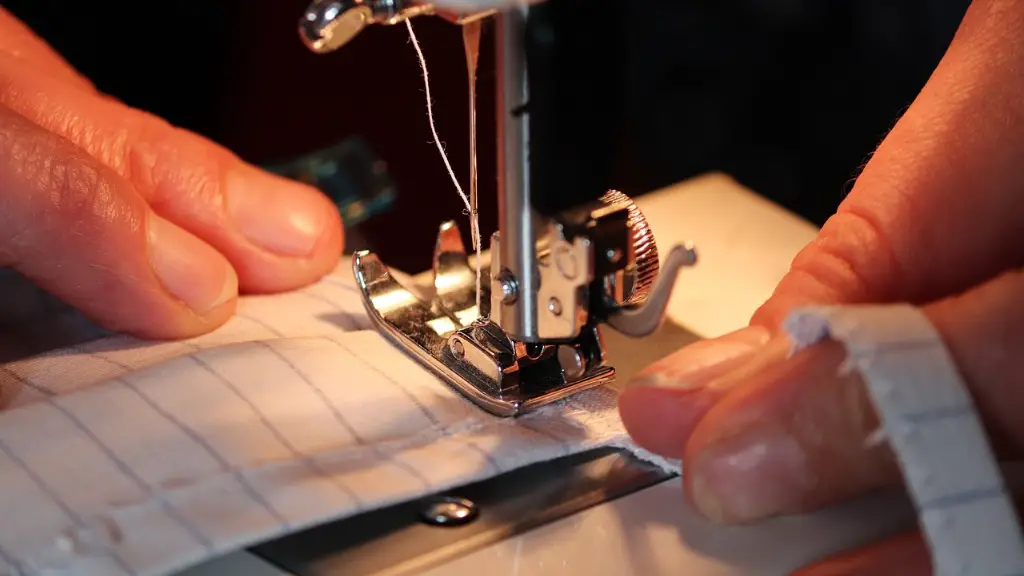

The first step in threading your sewing machine is to remove the bobbin holder and place the bobbin into the holder. The bobbin should fit snugly into the holder and should not require any additional support. Once the bobbin is in the holder, you can then take the thread hooks and attach them to the pins located on the bobbin holder. The hooks should be threaded through each pin and then tightened to ensure that the bobbin holder is securely attached to the sewing machine.

Threading the Upper and Lower Loops

Now that the bobbin holder is secured to the sewing machine, it is time to thread the upper and lower loops of the bobbin holder. To do this, you will want to find the hole located on the side of the bobbin holder that is closest to the back of the sewing machine. This hole is usually labeled as “top” or “Upper” on the bobbin holder. The threading hook should then be inserted into the hole and released after a few turns. This will create a small loop of thread that will be used to thread the upper loop of the bobbin holder.

Once the thread is looped through the hole, it is then time to thread the lower loop of the bobbin holder. To do this, you will want to locate the hole labeled as “Bottom” or “Lower” on the bobbin holder. Insert the threading hook into this hole and release it after a few turns. This will create a larger loop of thread that will be used to thread the lower loop of the bobbin holder.

Threading the Bobbin

Once the lower loop has been created, the bobbin can now be threaded. To thread the bobbin, manually wrap the thread around the bobbin several times in a clockwise direction. Make sure that the thread is wrapped around the bobbin spindle as well. Once the bobbin is fully threaded, it can be inserted back into the bobbin holder. Make sure to place the bobbin holder in the correct direction and then press down. This will secure the bobbin in place.

Adjusting Thread Tensions

The final step in threading the bobbin on a sewing machine is to adjust the thread tensions. To do this, you will want to locate the tension screws located on the bobbin holder. These screws should be loosened so that the bobbin can be moved freely in the holder. Beginning with the lower loop, you will want to adjust the tension knob until the bobbin loop is slightly tight when pulled with the threading hook. After the tension has been adjusted for the lower loop, adjust the tension for the upper loop in the same way.

Verifying The Threading

Now that the bobbin holder has been secured, the bobbin has been threaded and the tensions have been adjusted, the bobbin can now be tested. To do this, you will want to manually spin the bobbin several times with your hand. Be sure to pay close attention to the thread as it stretches around the bobbin holder. If the thread pulls away from the bobbin holder when it is tightened, then this indicates that the tension is too tight. If the thread pulls away from the bobbin holder when it is twisted, then this indicates that the tension is too loose. Both of these issues can be adjusted by adjusting the tension screws located on the bobbin holder.

Threading The Take-Up Lever

Once the threading of the bobbin has been verified, the final step is to thread the take-up lever. To do this, you will need to locate the hook on the take-up lever and thread it through the slot located on the side of the bobbin holder. Once the hook is in place, you can then use the threading hook to attach the yarn to the hook on the take-up lever. Make sure to check the direction that the thread is going as it is threaded onto the hook. Once the thread is on the hook, you can then wind the take-up lever several times to ensure that the thread is properly secured.

Checking The Results

Once the thread has been attached to the bobbin holder and the take-up lever has been wound, you can now test your results. To do this, you will want to turn the wheel on the sewing machine so that the needle is in the up position. Be sure to pay close attention to the thread and make sure that it is looping correctly around the bobbin holder and the take-up lever. After the bobbin thread and the take-up lever have been tested, you can then start sewing.

Changing Bobbins

Bobbins will need to be changed periodically in order to ensure that your projects run smoothly. If you are using a single bobbin machine, then you will need to remove the bobbin holder, empty the current bobbin, refill it with new thread, and reattach the bobbin holder. If you are using a double bobbin machine, then you will need to remove the first bobbin and reattach the second. It is important to note that when changing bobbins, you should always make sure that the thread is properly tightened and securely attached to the bobbin holder and the take-up lever.

Learning The Basics of Bobbin Threading

Learning how to set up a bobbin on a sewing machine can be a daunting task. However, once you understand the basics, it is a fairly straightforward process. Make sure to follow all the steps outlined above, and to always check the threading and tension settings to ensure that your projects run smoothly. With a little practice, you will soon become an expert at threading bobbins on a sewing machine.

Practice Makes Perfect

As with any new skill, practice is essential when it comes to learning how to properly thread a bobbin on a sewing machine. Before beginning any project, it is important to take some time and practice threading the bobbins. This will allow you to become familiar with the process and will give you an opportunity to troubleshoot any potential issues before beginning your project. With a little bit of practice and patience, you will soon be an expert at threading bobbins on a sewing machine.

Troubleshooting Common Bobbin Issues

When it comes to threading a bobbin on a sewing machine, there are certain issues that can cause problems. If you find that the thread is not looping around the bobbin holder properly, then this could be an indication that the tension is too tight. Additionally, if the thread keeps coming off the bobbin holder, then this could be an indication that the tension is too loose. Both of these issues can be corrected by adjusting the tension on the bobbin holder.

Safety Tips to Keep in Mind

When it comes to threading a bobbin on a sewing machine, it is important to keep safety in mind. Always wear appropriate safety glasses or goggles when handling small parts and sharp needles. Additionally, make sure to take your time and pay close attention to the threading process. Doing so will help to eliminate any potential problems that could occur if the thread is not properly looped around the bobbin holder.